My Shopping Cart

My Shopping Cart

Kickstart BIO 25 is a balanced soil-applied starter containing Nitrogen, Phosphorus, and Potassium combined with a comprehensive range of micronutrients and a humic-based biological soil ameliorant. This formulation promotes strong root establishment and efficient nutrient uptake during the critical early stages of crop growth. Its unique fermented humic base, enriched with proteins, carbohydrates, vitamins, and amino acids, helps stimulate soil biology and plant metabolism for healthy, vigorous development.

Designed for both in-furrow and fertigation applications, Kickstart BIO 25 rapidly delivers essential nutrients into the root zone and enhances nutrient translocation throughout the plant. The humic and fulvic acid base ensures nutrients are retained in the soil and remain plant-available, making it ideal for improving early crop performance and establishment across a wide variety of soils and crops.

| Component | % w/v | % w/w |

|---|---|---|

| Nitrogen (as Urea) | 8.5 % w/v | 7.2 % w/w |

| Phosphorus (as Phosphoric Acid & Monobasic Phosphate) | 6 % w/v | 11.8 % w/w |

| Potassium | 2 % w/v | 2 % w/w |

| Sulphur (as Sulphate) | 4.2 % w/v | 3.6 % w/w |

| Magnesium (as Sulphate) | 1.4 % w/v | 1.2 % w/w |

| Zinc (as Sulphate) | 3 % w/v | 2.6 % w/w |

| Iron (as Sulphate) | 0.2 % w/v | 0.17 % w/w |

| Manganese (as Sulphate) | 1 % w/v | 0.8 % w/w |

| Copper (as Sulphate) | 0.2 % w/v | 0.17 % w/w |

| Boron (as Boric Acid) | 0.5 % w/v | 0.4 % w/w |

| Molybdenum (as Molybdate) | 0.03 % w/v | 0.026 % w/w |

| Biostimulant (as Seaweed Ferment & Fulvic Acid) | 25 % w/v | 21 % w/w |

| Characteristic | Value |

|---|---|

| Colour | Clear |

| Specific Gravity | 1.14 - 1.20 |

| pH | 1.5 - 2.5 |

| Sizes Available | 20 Litre, 200 Litre, 1000 Litre |

| Crop Type | Rate / ha | Application |

|---|---|---|

| Cotton | 8 L | Apply in furrow at planting using 30 - 100 L of water per hectare |

| Maize, Soybean, Sorghum, Navy Bean, Mung Bean, Cereals, Canola | 10 L | Apply in furrow or through dripper immediately after planting |

| Turf | 3 L / 1000 m² | Apply via irrigation as required |

| Cucurbits | 5 - 10 L | Apply via fertigation immediately after planting to assist establishment; can be tank mixed and applied by waterwheel at transplanting |

| General Foliar Application | 1 L / 100 L water | Apply over foliage as required |

| Container Type | Dimensions (mm) | Weight | Pallet / Load Details | Notes |

|---|---|---|---|---|

| 20 Litre Drum | 280 × 220 × 420 | 30 kg per drum | — | Used for smaller AgroBest product batches or specialty formulations. Compatible with standard freight and pallet shipments. |

| 200 Litre Drum (on Pallet) | Individual Drum: 590 × 590 × 920 Pallet Pack: 1200 × 1200 × 1050 |

260 kg total per pallet | 1–4 drums per pallet configuration | Ideal for bulk quantities of AgroBest crop nutrition or protection products. Provides safe, stable transport on standard pallets. |

| 1000 Litre IBC | 1200 × 1000 × 1160 | 1300 kg total | Forklift and pallet-jack compatible | Preferred for large-scale AgroBest liquid fertiliser, brine, or nutrient storage. Suitable for high-volume distribution. |

*All sizes and weights are approximate and may vary slightly depending on the specific AgroBest formulation and packaging batch.

Kickstart BIO 25 provides the ideal nutrient foundation for young plants, combining a complete NPK and trace element package with humic and fulvic acids for enhanced soil and plant performance. Its fermented humic base stimulates microbial activity and root growth while improving nutrient retention and availability. Designed to complement granular fertilisers, Kickstart BIO 25 helps crops establish quickly, strengthens early plant vigor, and ensures uniform growth. Suitable for use across cereals, cotton, vegetables, legumes, and turf, it is an essential starter fertiliser for improving yield potential from the ground up.

How does Kickstart BIO 25 improve early root development and nutrient uptake?

Kickstart BIO 25 enhances root establishment and nutrient use efficiency through its unique biological and chemical composition. It contains humic and fulvic acids that boost soil microbial activity and nutrient availability, helping plants develop stronger roots and improved early vigor. Key benefits include:

By providing a fast, balanced nutrient boost with biological soil stimulation, Kickstart BIO 25 ensures crops get the strong start needed for sustained growth, yield, and productivity.

| File | Title | File Description | Type | Section |

|---|---|---|---|---|

| Kickstart_Bio25_2022.pdf | Kickstart BIO 25 - Soil Applied NPK + Trace Elements for Root and Crop Establishment | Kickstart BIO 25 is a soil-applied NPK starter with trace elements and humic acids that enhance root growth, nutrient uptake, and early crop establishment. | Catalogue | Document |

Phytophthora root rot is a destructive soil-borne disease of olive trees caused by Phytophthora species (water-mould pathogens). At least seven Phytophthora species have been identified attacking olives in Australia . These pathogens infect roots and can extend into the lower trunk, causing root decay and crown cankers that girdle the tree. If left untreated, Phytophthora root rot can kill olive trees, either through a rapid collapse or a slow decline over several seasons . The disease has been observed in many olive-growing regions worldwide, often linked to periods of excessive soil moisture.

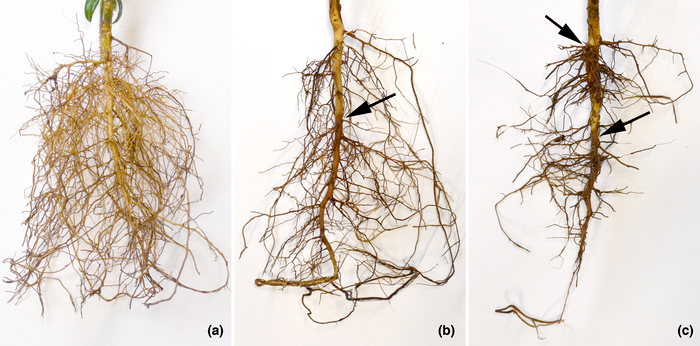

Symptoms: Infected olive trees typically show a loss of vigour and drought-like symptoms even when soil moisture is adequate. Foliage becomes sparse as leaves wilt, turn yellow, and drop prematurely . Shoot dieback starts at the tips of branches and progresses downward. In advanced cases, entire limbs or the whole canopy may wilt suddenly, especially under stress conditions like hot weather, flowering or heavy fruit load . Root and trunk symptoms include soft brown rot of feeder roots and lesion-like cankers at the crown or lower trunk; peeling back bark at the base often reveals reddish-brown discoloration of the wood. Affected trees may respond by shooting new suckers from the lower trunk or roots as the upper canopy dies back . Over time, the trunk can exhibit cracks or distortions due to the underlying canker damage . In some cases, trees can decline gradually over years, whereas in other cases they collapse quickly when the compromised root system can no longer support the canopy (for example, during a heatwave or late summer) .

Waterlogging and Poor Drainage: Excess soil moisture is the single biggest contributing factor to Phytophthora root rot in olives. Phytophthora thrives in saturated, oxygen-deprived soils. Australian conditions have consistently found Phytophthora outbreaks correlated with waterlogged conditions, claypan soil layers, or generally poor drainage in groves. Even a short period of waterlogging (as little as 24 hours) in warm temperatures can kill fine olive roots and predispose trees to infection. Low-lying orchard areas, heavy clay soils that drain slowly, or sites with a high water table create ideal conditions for the pathogen. It’s important to note that while waterlogging is a common trigger, Phytophthora can sometimes cause problems even in well-drained soils if the pathogen is present and environmental conditions (temperature, soil moisture) become favourable. In high-rainfall climates or during unusually wet seasons, otherwise well-drained olive blocks may still experience Phytophthora issues if drainage cannot keep up with prolonged rainfall.

Susceptible Rootstocks: Most olive trees in Australia are grown on their own root stock (i.e., not grafted), but in cases where different rootstocks or wild olive (Olea europaea subsp. africana) seedlings are used, susceptibility can vary. Caution is advised when using feral/wild olive trees as rootstocks or nursery stock. These plants can originate from areas where Phytophthora is present in the soil and may introduce the pathogen or be less tolerant to it. There is currently no widely available Phytophthora-resistant olive rootstock, so all varieties should be assumed susceptible. Research by Spooner-Hart et al. noted that the emergence of Phytophthora problems in Australian olives has coincided with the expansion of plantings into non-traditional (non-Mediterranean) climates and heavier soils. This underscores the role of environment and rootzone conditions in disease incidence.

Warm, High-Rainfall Climates: Olives are traditionally adapted to Mediterranean climates (winter rain, dry summers). In parts of Australia with warm temperatures and summer-dominant rainfall (e.g., coastal Queensland and northern New South Wales), the risk of Phytophthora root rot is higher. The pathogen is widespread in soils and waterways in these regions and can easily infect olive roots when wet, warm conditions persist. Growers in such climates must be especially proactive with prevention measures. High humidity and frequent rain not only favor the pathogen but can also mask early drought-stress symptoms - an infected tree might not show obvious distress until a dry period or heat event reveals the extent of root loss.

Disease Spread: Phytophthora produces motile spores (zoospores) that swim in free water, so the pathogen spreads with water movement through soil and runoff. It can be introduced or spread in a grove via infected nursery stock, contaminated soil on equipment, flood irrigation water, or even the boots of workers moving from an infested wet area to a clean area. Once in the soil, Phytophthora can persist for years in root debris or as resilient spores. Thus, any practice that moves soil or water (e.g., tractor(s) and farm equipment, drainage flows) from an infected zone to an uninfected zone can facilitate the dissemination of the disease. Growers should avoid transferring mud and material from known infested blocks and ensure any new trees planted are from disease-free sources (pathogen-free).

Successful management of Phytophthora root rot in olives relies on an integrated strategy. This includes preventative chemical treatments, supportive nutritional therapies, and cultural practices to improve soil conditions and reduce pathogen spread. The goal is to protect healthy roots from infection, eradicate or suppress the pathogen in soil where possible, and help affected trees recover. Below are the current industry best practice:

Phosphorous acid (also known as phosphonate or phosphite) is a key fungicide for mana PhozGuard 620 Phytophthora in many tree crops and is a cornerstone of preventative treatment in olives. Phosphonate does not act like a typical fungicide that directly kills the pathogen on contact, instead, it works by inhibiting Phytophthora growth and stimulating the tree’s own defense mechanisms. This dual mode of action makes it most effective as a preventative treatment, applied before or at the very early stages of infection, to help the plant resist invasion. Phosphorous acid is available under various trade names (e.g., Phosguard620) with different concentrations of active ingredient. Always confirm that the product is permitted for use on olives and follow the label or permit directions.

Application timing and rates: On woody perennial crops like olives, foliar sprays of phosphonate are typically applied approximately every 6 weeks during the growing season for ongoing protection. This ensures a consistent level of the fungicide within the plant, as it is systemic and will move into the roots. Label rates depend on product concentration; for example, products with around 600 g/L a.i. are used around 2.5 mL/L, 400 g/L formulations at 5 mL/L, and 200 g/L formulations at 10 mL/L (when applied with an air-blast sprayer to fully cover the foliage). For young or small olive trees, high-volume spraying to runoff ensures good coverage. Crucial timing is just before periods of high risk - e.g., before winter rains or summer wet spells - so that the roots are protected in advance.

In situations where an olive tree has very little foliage left (severe defoliation from root rot), phosphonate can be applied as a bark spray or trunk injection. Spraying a ~10% phosphorous acid solution directly on the trunk or injecting the solution into the lower trunk can deliver the fungicide to the vascular system when leaves are insufficient. Trunk application is usually done in autumn or spring when the tree is actively translocating, to maximise uptake. Always exercise caution with concentrated trunk sprays to avoid phytotoxicity and adhere to recommended concentrations carefully.

Mode of action and benefits: Once absorbed, phosphonate is translocated downward with the sap flow, reaching the roots and inhibiting Phytophthora in infected tissues. It also primes the tree’s immune response. Treated trees often show not only disease suppression but also improved new root development in some cases. Phosphonate is valued for being relatively inexpensive and having low toxicity to humans and non-target organisms, making it a practical choice for routine preventative use. In warm, high-rainfall regions of Australia where Phytophthora is endemic, applying phosphonate prophylactically to young olive trees can protect them until their root systems establish. Many agronomists recommend an initial phosphonate spray or injection soon after planting in such regions, followed by periodic treatments during the wet season.

It’s important to remember that phosphonate is a suppressive, not an eradicant, treatment. It significantly reduces Phytophthora levels and activity in the tree but does not eliminate the pathogen from the soil. Therefore, repetitive or at least annual reapplications are needed to maintain protection. If treatments are stopped, Phytophthora can rebound if conducive conditions return. Also, phosphonate works best on preventing new infections and halting early disease - severely diseased trees (with the majority of roots already rotted) may not recover with fungicide alone. In those cases, phosphonate can only prevent further spread while other measures support the tree’s regrowth.

Other fungicides: Another chemical option is metalaxyl-M (e.g., Ridomil Gold), a systemic fungicide specifically targeting oomycete pathogens like Phytophthora. Ridomil can be applied as a soil drench or via injection to kill Phytophthora in the root zone. It has shown effectiveness in olives, but similar to phosphonate, it does not sterilise the soil and must be reapplied periodically to keep the pathogen in check. Phosphonate is often preferred for long-term management due to lower cost and resistance risk, but Ridomil drenches can be useful as a curative kick-start in heavily infested soils or to protect newly planted high-value trees. Always rotate or mix chemical modes of action as allowed, to prevent the development of fungicide resistance in the Phytophthora population.

As an example for conventional application... Calcium nitrate at 10 g/L plus Solubor (boron) at 1.5 g/L, mixed in water, applied as a fine foliar spray every 6 - 8 weeks. Calcium nitrate provides a readily absorbed form of calcium (along with some nitrogen to spur growth), and Solubor is a common soluble borate fertiliser that assists to correct boron deficiency. These can be tank-mixed and sprayed to cover the foliage; ideally, apply in the cooler part of the day (morning or late afternoon) to reduce the risk of leaf burn. Liquid boron applications like Agrodex Boron are usually recommended.

In addition to fungicides, nutritional support plays a critical role in managing Phytophthora root rot - especially for helping infected trees recover. Two nutrients in particular, calcium (Ca) and boron (B), have been observed to assist olive trees suffering from root rot. Calcium and boron are closely associated with the growth of new shoots and root tips; they are essential for cell wall strength (Ca) and cell division/floral development (B). Some olive varieties have relatively high requirements for Ca and B compared to other fruit trees, and deficiencies of these nutrients often manifest as dieback of shoot tips (boron deficiency can cause tip death and poor new leaf growth, while calcium deficiency leads to weak stems and twig dieback).

When roots are compromised by Phytophthora, the tree’s ability to uptake nutrients from the soil is severely impaired. Ailing roots mean even if fertilisers are in the soil, the tree may still suffer from nutrient deficiencies. Foliar feeding can bypass the damaged root system and deliver nutrients directly to the leaves and young shoots. Foliar sprays of calcium and boron have shown positive results in reducing twig dieback and stimulating new growth on moderately affected olive trees. The recommended practice (from field experience in Australia) is to apply calcium and boron together on a regular schedule during the active growing season:

It’s worth noting that while calcium and boron are the focus for tip dieback, other nutrients should not be neglected. Trees battling root rot might also benefit from magnesium (for chlorophyll), zinc (for hormone production), and other micronutrients if deficient. However, over-applying any one element can cause imbalances or toxicity (boron, for instance, can be toxic above recommended rates). Stick to label rates and recommended concentrations for all foliar feeds, and monitor leaf nutrient levels if possible. The Ca+B foliar program should be seen as one component of a broader nutritional management plan for stressed trees. Start with Soil and/or Leaf Analysis to ascertain data from your grove.

Beyond calcium and boron, a complete foliar nutrient program is advised for olive trees with significantly impaired root systems. Because root rot limits uptake of both macro- and micro-nutrients, foliar applications of a balanced fertiliser can supply the tree with essential nutrients until roots recover. Many agricultural suppliers offer soluble foliar fertiliser blends (NPK plus Trace Elements) that can be sprayed on the canopy. These blends often contain nitrogen, phosphorus, and potassium, as well as micronutrient like zinc, manganese, iron, copper, molybdenum, etc., in plant-available forms. Applying such a foliar feed can green up a chlorotic, declining tree and promote new leaf and root development while bypassing the diseased root system.

A suggested regimen is to spray a complete foliar fertiliser (for example, an NPK 20-20-20 with trace elements, or a product formulated for orchard foliar feeding) on a monthly or bi-monthly schedule during the growing season. This can often be done in conjunction with the calcium nitrate and boron sprays - either by alternating them or, if compatibility is confirmed, combining them in one tank mix. Be cautious when mixing fertilisers with fungicides: phosphonate is generally compatible with many fertilisers, but always jar-test combinations or consult product labels.

Foliar nutrient programs should be tailored to the grove’s specific deficiencies. If leaf analysis or visual symptoms indicate particular nutrient shortages (e.g., yellowing between veins might indicate magnesium or iron deficiency, small, distorted new leaves could indicate zinc deficiency), include or emphasise those nutrients in the foliar mix. Maintaining good overall nutrition will improve the tree’s resilience. Stronger, well-nourished olive trees have a better chance to compartmentalise Phytophthora infections and resume normal growth once conditions improve. Remember that these sprays supplement but do not replace soil fertilisation; once roots recover function, reinstating a normal soil fertiliser program (adjusted for any residual soil fertility and the tree’s regained capacity) is important for long-term production.

Cultural controls that improve the soil environment are fundamental to managing Phytophthora - no chemical or nutrient can fully substitute for a well-drained root zone. Growers should evaluate their grove for any conditions that contribute to waterlogging or poor root health and take corrective action:

Both phosphonate fungicides and calcium-boron foliar feeds are important tools in managing Phytophthora root rot, but they serve different purposes and have distinct advantages and limitations. It’s not an either/or choice - in fact, they are complementary in a comprehensive management program. Below is a comparison to clarify their roles for growers:

It’s also worth comparing phosphonate with the other fungicide option, metalaxyl (Ridomil). Phosphonate and Ridomil both suppress Phytophthora, but in different ways. Ridomil is more of a curative, directly toxic to the pathogen, whereas phosphonate has those immune-boosting properties. Ridomil can knock back an active infection faster, but it has a higher cost and a risk of resistance development in the pathogen population with overuse. In practice, phosphonate is often used for regular protection, and Ridomil (if used at all) might be reserved for spot-treating severe cases or as a pre-plant soil drench in known infested sites. Both chemicals require reapplication; neither provides permanent protection. Always follow an Integrated Disease Management philosophy when using these tools - they are most effective when combined with the cultural and nutritional strategies described above.

Managing Phytophthora root rot requires an Integrated Disease Management approach, especially in Australia’s warm, high-rainfall olive-growing regions. No single intervention is a silver bullet; instead, growers should implement a suite of preventive and remedial measures that together minimise disease impact. Below is a summary of IDM practices for Phytophthora root rot in olives:

Managing Phytophthora root rot in olives is challenging, but with vigilant management, it is possible to minimise losses and even restore affected groves to health. The keys are prevention (through site selection, drainage, and preventative fungicides) and support (through nutrition and careful cultural care for stressed trees). Australian olive growers should view Phytophthora management as an ongoing part of grove management, much like pruning or pest control, especially in regions prone to heavy rainfall. By implementing the integrated strategies outlined above, growers can significantly reduce the impact of Phytophthora root rot, protecting their trees and investment. Remember that every grove is different - monitor your olive trees closely and adapt these recommendations to local conditions, and always reference current guidelines from olive industry research and local agricultural authorities. With a proactive, informed approach, even the threat of “root rot” can be managed, and olive trees can continue to thrive and produce in the Australian landscape.

AgroBest is an Australian manufacturer with a wide range of crop protection and liquid fertiliser products to help keep your olive trees healthy and productive. This guide gives you a practical overview of the AgroBest range available through The Olive Centre and how they can fit into your nutritional grove program across the season. We’ll walk through foliar feeds, soil conditioners, pest and disease support products, spray adjuvants and biostimulants, explaining when to use, and how to help with common olive problems. Whether you’re dealing with nutritional needs or tired trees that just aren’t performing, this guide is designed to help you quickly match the right AgroBest product to the needs of your grove. A soil and leaf analysis are recommended to narrow down the correct product(s).

Foliar nutrition is critical for addressing immediate nutrient needs and boosting olive tree productivity. AgroBest offers several NPK foliar fertilisers and trace element sprays designed for quick uptake through leaves. These products provide balanced macronutrients (nitrogen, phosphorus, potassium) often enhanced with micronutrients or biostimulants to improve efficacy.

Healthy soil is the foundation of productive olive groves. AgroBest offers products that improve soil fertility, structure, and microbiology - ensuring roots have access to nutrients and water. These soil conditioners and granular/liquid fertilisers are applied to the soil (via drench, fertigation, or banding) rather than sprayed on foliage.

Using these soil-oriented products, olive growers can address issues like poor soil fertility, low organic matter, or imbalanced nutrients in the root zone. For instance, if an olive grove is suffering from nutrient lock-up or weak root growth, a combination of humic-enriched Kickstart and organic GroMate can rebuild soil life. If soil calcium or pH is an issue, products like CarboCal can supply calcium in a plant-accessible form that strengthens soil and trees alike. Healthier soil translates to stronger, more resilient olive trees with better uptake of nutrients and water.

While AgroBest’s focus is on nutrition, some of its products also play a role in crop protection - either by directly deterring stresses or by strengthening the plant against pests and diseases. Olive growers face challenges such as black scale insects, fungal diseases like peacock spot and anthracnose, as well as environmental stresses (frost, heat) that can predispose trees to problems. AgroBest products can be part of an integrated strategy to tackle these issues.

It’s important to note that AgroBest does not produce synthetic pesticides or fungicides - instead, their offerings focus on prevention and plant strength. For active infestations like a severe black scale attack or an anthracnose epidemic, growers would still use specific registered pesticides (e.g. a petroleum spray or an IGR for scale, or a copper fungicide for anthracnose/fungal issue). However, integrating AgroBest products could mean fewer such interventions are needed. By using nutritionals and protectants like Envy and Spraytech Oil proactively, olive growers can reduce stress and pest pressure on their groves. This integrated approach leads to a more sustainable pest and disease management, leveraging plant health to fight off challenges naturally. Always test product compatibility before mixing.

Adjuvants are “helper” products that improve the performance of agrochemical sprays - ensuring that nutrients or pesticides stick as intended. AgroBest’s adjuvants are especially valuable in olive production, where the undersides of leaves and the waxy surfaces of olive foliage can make spray coverage difficult. Using the right adjuvant means more of your spray actually reaches the target and stays there, rather than bouncing off or drifting away. Two key adjuvant products in the AgroBest range are:

AgroBest AgroChelate - An organic acid concentrate used as a water conditioner, compatibility agent, and nutrient uptake enhancer. Agro “Chelate” is essentially a blend of organic acids and amino acids. When added to a spray tank or fertigation system, it acidifies the solution slightly (bringing pH to a plant-friendly level), chelates micronutrients (preventing them from reacting with other chemicals or getting locked up), and improves the mixing of otherwise incompatible inputs. For example, olive growers often want to tank-mix calcium with phosphorus fertilisers or combine multiple trace elements - this can cause precipitation or antagonism. AgroBest’s Chelate product helps keep such mixes stable and ensures the nutrients remain in a form the plant can absorb. It also acts as a mild biostimulant due to its amino acid content, so foliar feeds with AgroChelate might show improved uptake into leaves. In summary, Agro Chelate is used as an adjuvant to condition spray water (especially if it’s alkaline or hard), to prevent clogging and leaf burn, and to facilitate smooth absorption of nutrients through the leaf cuticle. It’s particularly useful in foliar trace element programs and fertigation systems. (Available in liquid form; e.g. 5L and 20L containers.)

Using adjuvants like these is highly recommended in olive spray programs. Olives have small, waxy leaves and a dense canopy; getting sprays to penetrate and stick can be challenging. By using Spraytech OIL, growers report more uniform coverage and better results from both pest control and foliar feeding efforts (the improved uptake means you might achieve desired results with lower application rates, saving cost). Similarly, with AgroBest’s chelating adjuvant, complex tank mixes become more stable - meaning you can, for instance, mix your zinc, boron, and magnesium foliar feeds with confidence that each will remain available to the tree. In sum, AgroBest adjuvants ensure you get the maximum benefit from every spray, an important consideration given the time and cost involved in spraying an olive grove.

Biostimulants are products that don’t fit the traditional “fertiliser” mould of simply providing N-P-K, but instead contain natural compounds (like seaweed extracts, humic acids, beneficial microbes, etc.) that enhance plant growth and resilience. AgroBest has embraced this technology by offering several biostimulant products that can give olive trees an extra edge - improving root growth, boosting stress tolerance, and increasing nutrient uptake efficiency. These are especially relevant to olives, which often face stresses like drought, high salinity, and poor soils.

By integrating biostimulants into their regime, olive growers can tackle challenges like nutrient-poor soils, irregular bearing, or climate stress in a more natural way. For example, facing a scenario of “off-year” in an alternate-bearing olive grove, one might apply SeaFil or Fulfil to reinvigorate the trees and potentially improve the next bloom. In drought-prone areas or saline irrigation conditions, biostimulants help olive trees maintain growth and yield where they otherwise might suffer. These products do not replace standard NPK fertilisers but rather supplement the nutrition program by ensuring that the plant can make the most of nutrients and overcome growth hurdles. They are akin to vitamins and probiotics for your olive trees - not absolutely required, but when used properly, they often lead to healthier, more productive plants.

Product Sizes & Usage Note: Most AgroBest biostimulants are available in various sizes to suit different scales of operation - from 1-5 L bottles for small groves up to 200 L drums for large farms. They are generally applied at low concentrations (e.g. a few litres per hectare as a foliar spray). It’s important to follow recommended timing - many biostimulants show best results when applied at specific growth stages (like root flush, pre-flowering, or stress events).

In Australian agriculture, understanding the hidden nutrients in your soil and plants can make the difference between an average harvest and a thriving one. Leaf and soil analysis give farmers, agronomists, olive growers, and even hobby gardeners a scientific window into their crops’ health. By regularly testing both the soil and the leaves (foliage) of your olive trees or other plants, you gain precise data to fine-tune fertiliser use, correct deficiencies, and boost overall productivity. The result is healthier olive groves, higher yields of quality fruit, and more sustainable soil management - an investment that pays off in both the short and long term through improved crop performance and soil health.

In Summary, AgroBest’s range of products on The Olive Centre spans everything from core fertilisers to innovative biostimulants, all geared toward improving plant nutrition and resilience. By grouping products into foliar feeds, soil conditioners, protection aids, adjuvants, and biostimulants, we see that each category addresses different aspects of olive grove management:

Sources: The information in this article is from The Olive Centre’s product listings and knowledge base, including technical descriptions of AgroBest products and their recommended uses. Each product mentioned is available through The Olive Centre; for detailed application rates and guidelines, please refer to the specific product pages and labels. By reviewing these resources and field experiences, we’ve provided an integrated overview to help you make informed decisions about which AgroBest products can best address the needs of your olive grove.

Introduction

Managing a professional olive production enterprise requires a holistic operational system that covers every aspect of grove management – from seasonal field practices to financial tracking and technology integration. This report outlines a comprehensive system designed for professional olive producers in Australia (with relevance internationally), detailing best-practice management structures, cost tracking methods, data monitoring and decision-support tools, forecasting techniques, and ready-to-use workflows and templates. By implementing a structured approach with clear planning, recordkeeping, and modern tech integration, olive growers can improve productivity, sustainability, and profitability. The following sections break down the components of this system with practical guidelines and examples.

Effective olive grove management is multi-faceted, involving year-round planning and execution of tasks. It is helpful to organise these tasks by season and category, ensuring nothing is overlooked throughout the year. Table 1 provides an overview of key seasonal activities in an Australian context (southern hemisphere), which can be adjusted for other regions (the timing of seasons will differ in the northern hemisphere ). Each activity should be supported by detailed record-keeping and adherence to best practices for orchard maintenance, irrigation, nutrition, pest control, pruning, and harvest.

Proactive seasonal planning is vital. By mapping out activities month-by-month, growers can ensure each critical task is done at the right time. Many producers use a yearly task calendar or planner to schedule operations. For example, the Australian Olive Association’s Yearly Orchard Planner outlines monthly tasks ranging from machinery servicing in the off-season to timely fertiliser applications and harvest prep. Such a planner ensures cross-over tasks (e.g. tractor maintenance benefiting both grove and other farm enterprises) are efficiently scheduled. It’s important to adjust the calendar to local climate patterns and whether the grove is in the southern or northern hemisphere. Regular planning meetings (e.g. before each season change) can help assign responsibilities and resources for upcoming tasks.

Accurate record keeping underpins all aspects of the operational system. Every activity – from spray applications to harvest yields – should be logged. This not only aids internal decision-making but also is often required for compliance (e.g. chemical use records) or quality assurance programs (such as the OliveCare® code of best practice ). Key records to maintain include:

General orchard maintenance activities ensure the grove’s long-term health and accessibility. These include ground cover management, upkeep of equipment, and maintaining the orchard environment:

Efficient water management is crucial for olive production, especially in Australia’s climate, where seasonal droughts are common. Olives are relatively drought-tolerant, but strategic irrigation greatly improves yield and oil quality in most Australian growing regions. Key components of irrigation management include:

Overall, irrigation in an olive operational system should be proactive and precision-focused. Given water scarcity concerns, Australian producers in particular benefit from these efficient practices – a fact evidenced by large groves like Boundary Bend investing heavily in irrigation technology research to “use less water but retain optimum productivity”. Well-managed irrigation not only saves water and energy, but also directly contributes to consistent yields and oil quality.

Proper fertilisation of olive trees ensures they have the nutrients needed for vegetative growth, fruiting, and recovering after harvest. The nutrition program should be based on soil and leaf analysis plus the grove’s yield goals. Key points include:

Pest and disease management in olives should follow an Integrated Pest and Disease Management (IPDM) approach. This means using a combination of monitoring, cultural practices, biological controls, and chemical controls when needed. Key elements for a professional group include:

Pruning is a cornerstone of olive grove management, directly influencing yield, tree health, and harvest efficiency. A well-structured pruning program in a professional system includes:

Harvest is the culmination of the season and requires careful logistical planning to execute efficiently and preserve fruit quality. A comprehensive operational system addresses harvest in several ways:

By detailing harvest logistics in the operational system, a grower ensures that this critical period is handled smoothly. It’s often said that in olives, “90% of the quality is influenced by what happens on the farm” – timely harvest and proper handling are a big part of that. Thus, the comprehensive plan treats harvest not as a rushed event but as a well-orchestrated project each year.

Understanding and controlling the cost of production is essential for a sustainable olive business. This part of the system involves setting up templates and tools to track all costs, from orchard inputs to labour and equipment, and calculating metrics like cost per hectare and cost per tonne of olives (or per litre of oil). A professional approach includes:

| Cost Category | Example Items | Cost (AUD/ha) | Share of Total (%) |

|---|---|---|---|

| Labour – Harvest | Picking crew wages or harvester contract, supervision, and fuel | $1,200 | 35% (highest single cost) |

| Irrigation | Water purchase, pumping energy (diesel/electric), irrigation maintenance parts | $600 | 18% |

| Fertilisation | Fertilisers (N, P, K), soil amendments, and application labour | $550 | 16% |

| Pruning | Labour or contract pruning, tool maintenance, brush mulching | $450 | 13% (varies by manual vs mechanical) |

| Pest & Disease Control | Pesticides, fungicides, traps, application labour (spraying) | $300 | 9% |

| Other Labour (non-harvest) | Irrigation management, mowing, and general supervision (portion of manager wages) | $200 | 6% |

| Machinery & Fuel | Tractor fuel, maintenance, depreciation (portion allocated) | $150 | 4% |

| Miscellaneous | Monitoring tech, insurance, admin, etc. | $100 | 3% |

| * Total (per hectare per year) | $3,550 | 100% | |

Table Note: The above breakdown is illustrative. Actual costs will differ by grove and system (e.g. superintensive groves might have higher harvest costs due to machinery leases but lower per-unit labour, etc.). The IOC study figures in the table (italicised) are from a traditional system example and show the relative importance of harvest, irrigation, and fertiliser inputs. Tracking your own costs allows you to refine these numbers for your operation.

Modern olive farming can greatly benefit from data-driven decision support, using sensors and information technology (the realm of IoT – Internet of Things and smart farming). Integrating such systems into daily operations turns raw data (weather, soil moisture, pest counts, etc.) into actionable insights. In this comprehensive system, the following integrations are recommended:

To run a sustainable olive operation, one must not only react to the present conditions but also anticipate the future. Forecasting tools help in predicting yields, planning resources and finances, and strategising for the long term. This section details how to incorporate forecasting into the operational system:

In the operational system, it’s wise to formalise yield forecasting. For instance, schedule a “yield forecast review” meeting mid-season (maybe 6–8 weeks post flowering) to discuss all available info (fruit set, tree health, etc.) and come to a forecast. Update it again just before harvest with more solid numbers (e.g. from sample picking an olive bin from a tree or small plot and weighing). Document these forecasts and later compare them to actual yield to improve your methods over time.

Forecasting is not only about yield – it’s equally about financials. A robust operational system will include:

By treating budgeting and financial forecasting as an integral part of the operational system (rather than an afterthought at tax time), professional growers ensure that agronomic decisions are grounded in financial reality. It also impresses stakeholders (banks, investors) when the business can show proactive financial planning.

Beyond the annual scale, a comprehensive system should guide strategic planning over the long term:

To translate all the above components into day-to-day action, the system should provide clear workflows and ready-to-use templates. These resources ensure consistency, save time, and serve as training tools for staff. Below are some of the key templates and checklists recommended, along with their purpose:

In the resources library of industry organisations, many of these templates are available. The Australian Olive Association, for instance, provides resources like the Yearly Orchard Planner, an IPDM manual, and other guides which include checklists and record sheets (often accessible to members). International bodies like the IOC or FAO have Good Agricultural Practices manuals that contain sample record forms. The key is to adopt and customise these to your farm’s needs, then consistently use them.

By having structured workflows and templates, the operation runs in a systematised way rather than relying on memory or ad hoc decisions. This reduces risk (e.g. missing a spray or forgetting to service something) and improves training – new staff can quickly learn the ropes by following established formats. Moreover, in the event a manager is away, the existence of clear checklists and templates means the team can continue to function with minimal disruption, since the “recipe” for tasks is documented.

To support the comprehensive system described, certain technologies and software tools are highly beneficial. Below, we provide recommendations for tools that are either commercially available or emanate from credible research institutions, ensuring they are reliable and suitable for professional use. These cover farm management platforms, specialised olive cultivation tools, and general agtech solutions:

In conclusion, a comprehensive operational system for professional olive producers weaves together agronomic best practices, detailed record-keeping, cost management, and technology integration and planning into one coherent framework. By implementing a structured management calendar, maintaining meticulous records of both activities and expenses, and leveraging modern sensors and software, growers can achieve a high level of control and insight into their operations. This system is designed to be holistic – covering the soil beneath the trees to the finances underpinning the enterprise – and adaptive, allowing for localisation (Australian conditions in this context, but with practices applicable globally) and continuous improvement as new knowledge or tools emerge.

Crucially, the system emphasises that planning and monitoring are as important as doing. Seasonal checklists and annual planners ensure proactive management rather than reactive firefighting. Cost templates and forecasting tools ensure that production is not just good in the grove but also economically sustainable. Meanwhile, data from IoT sensors and decision support models enable precision farming – applying the right intervention at the right time and place, which is both cost-effective and environmentally responsible.

Implementing this comprehensive system may require an initial investment in time (to set up templates, train staff) and capital (for technology or new equipment), but the returns are seen in higher yields, better quality, lower wastage of inputs, and improved ability to cope with challenges (be it a pest outbreak or a drought year). As demonstrated by progressive growers and supported by research, the integration of traditional olive cultivation wisdom with cutting-edge agtech forms the blueprint for the future of olive production.

By following the structured approach outlined in this report, professional olive producers in Australia – and those in similar olive-growing regions worldwide – can enhance the productivity and sustainability of their groves. They will be well-equipped to produce olive oil and table olives of the highest quality, with an operation that is efficient, resilient, and ready to capitalise on innovations and market opportunities. The ultimate goal of this system is to ensure that every aspect of the olive orchard, from bud to bottle, is managed with excellence and foresight – securing both the profitability of the enterprise and the legacy of the grove for years to come.

Sources: