An advisory update outlining recent Chinese export tax changes affecting glass bottles and jars, and what the removal of VAT rebates means for olive oil packaging costs and supply chains.

My Shopping Cart

An advisory update outlining recent Chinese export tax changes affecting glass bottles and jars, and what the removal of VAT rebates means for olive oil packaging costs and supply chains.

A professional comparison of the Guardian Gas Gun and Vinetech Electronic Bird Scare Gun, outlining operation, sound coverage, control features, compliance, and suitability for agricultural bird control.

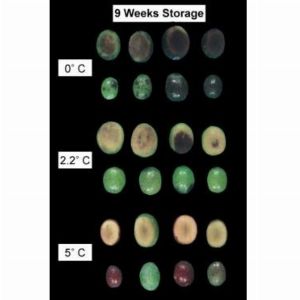

An in-depth guide to CO₂ chilling injury in fresh olives, explaining physiological disorders, storage risks, cultivar sensitivity, and practical strategies to minimise postharvest quality loss.

When planning irrigation for olive groves, it is important to understand the minimum water requirements needed to support healthy tree growth and fruit production.

Sansone stainless steel silos deliver premium, hygienic storage for olive oil, wine, honey, and liquid foods. Built with conical bases for complete drainage, they offer superior cleanliness, durability, and flexible capacity—trusted by producers who demand quality and long-term performance.

Sansone stainless steel containers deliver premium, food-safe storage for olive oil, honey, wine, and ferments. With airtight seals, light protection, and long-lasting durability, they maintain freshness and purity far better than plastic or glass.

Olive oil producers can enhance extraction efficiency and oil quality with the strategic use of processing aids. These materials, including talc, enzymes, salt, and citric acid, improve oil release, reduce paste viscosity, and help separate oil from water.

Reliable labelling machines are essential for accurate product identification, smooth production flow, and consistent packaging quality. This article explains how precision label feed, clean application, correct tension, and expert calibration directly influence reliability.

Pruning is one of the most powerful tools olive growers have to protect tree health, stabilise annual yield, and maintain efficient harvesting systems. This guide breaks down the core principles of training young trees, managing mature production canopies, and performing essential post-harvest clean-up to keep olive groves productive and balanced.

AgroBest’s range delivers a full, science-backed approach to olive grove nutrition and plant health, combining foliar feeds, soil conditioners, trace elements, adjuvants, and biostimulants into one integrated program. This review breaks down how each product works, which problems it solves, and when growers should use it for maximum effectiveness.