My Shopping Cart

My Shopping Cart

| Specification | Value |

|---|---|

| Model | DLE Junior |

| Production Capacity | 500 kg per hour |

| Water Consumption | 50 L per hour |

| Power Requirement | 1 kW |

| Dimensions | 100 cm × 150 cm × 200 cm (H) |

| Weight | 230 kg |

| Main Functions | Leaf removal, fruit washing, elevator transfer |

| Construction | AISI 304 stainless steel, food-grade components |

OLIVE OIL PROCESSING MACHINERY

Barigelli olive oil machinery installations detail the complete journey from fruit preparation to final oil extraction. Each installation shows how individual components-crushers, malaxers, decanters, and clarification systems - work in synchrony to deliver consistent, high-quality olive oil. The following sections summarise each functional stage of the production line, referencing installation examples.

This installation combines olive crushing and paste malaxing in a compact continuous system. The crusher prepares the olive paste uniformly before transfer to the malaxing tanks, where controlled mixing optimises oil separation. Integrated control settings manage paste temperature, timing, and batch flow to maximise extraction efficiency.

Image: Vertiical Separator with Stand, Malaxing Unit with Crusher, Decanter & Control Panel all connected with raceway.

This installation showcases the Barigelli BVD 6-10 olive oil extraction system equipped with an integrated control panel. The setup includes a crusher, malaxing system, and decanter, designed for continuous olive oil processing. The control panel allows operators to manage temperature, timing, and extraction parameters for optimal oil yield and quality.

Barigelli stainless steel vertical separator in operation, showcasing freshly extracted olive oil flowing smoothly from the outlet into the collection tank. The design ensures efficient liquid separation of oil while preserving aroma, colour, and quality of extra virgin olive oil.

Barigelli’s high-capacity decanter systems designed to separate oil, water, and solids in a single continuous process. The horizontal design ensures high separation efficiency, reduced energy consumption, and easy maintenance access for operators.

Barigelli Early Decanter Models and First Olive Oil Plant

Barigelli’s pioneering olive oil extraction technology - from the early B/D 400 (1995) and B/D 500 (1998) decanters to the B/DF 400H hydraulic version and the first complete olive oil plant (1998). These models mark the foundation of Barigelli’s innovation in continuous olive oil processing systems.

Barigelli Decanter and Mobile Extraction Units (2005 - 2009)

Barigelli’s advanced range of decanters and mobile olive oil extraction units developed between 2005 and 2009. The models include B/DF 125 (2007), B/DF 800H (2005), and B/DF 650 XLH (2009), alongside mobile versions such as the B/DF 125H (2008) and B/DF 400LH (2007). These systems represent a leap in continuous extraction technology, combining high efficiency, portability, and precision oil separation.

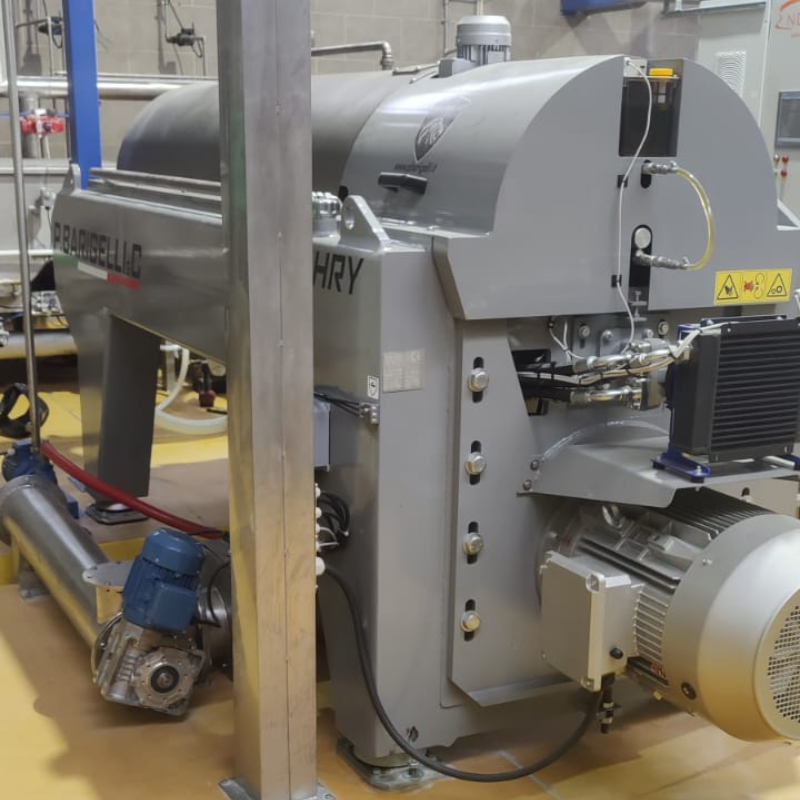

Barigelli 4.50 HRY olive oil extraction setup featuring stainless steel decanters, pumps, and separator units. The continuous line integrates crushing, malaxing, decanting, and final clarification, designed for high-capacity and consistent extra virgin olive oil production.

Barigelli CA 5.10 HRY decanter, a high-efficiency centrifuge designed for large-scale olive oil extraction. Built with precision stainless steel, the system separates oil, water, and solids in a continuous process, ensuring maximum yield and superior oil quality.

Different malaxing setups can be offered in a linear system, stacked or as a bank setup.

Barigelli Olive Oil Processing Installation

Barigelli Olive Oil Processing Installation on working

Oil clarification are critical steps that can help to maintain the purity, stability, and quality of extra virgin olive oil. Once oil has been separated in the decanter, it still contains microscopic solids, waxes, and water traces. Vertical separators separate unwanted parts to minimise fermentation and cloudiness, ensuring that the oil remains bright, aromatic, and longer-lasting. Barigelli systems feature stainless-steel food-grade modules integrated directly into the processing line, allowing continuous operation without halting production or creating bottlenecks. Their modular construction supports single or multi-stage malaxation.

Barigelli stainless-steel feed system with inline sight-glass valves and transparent inspection panels. Designed for continuous olive oil feed.

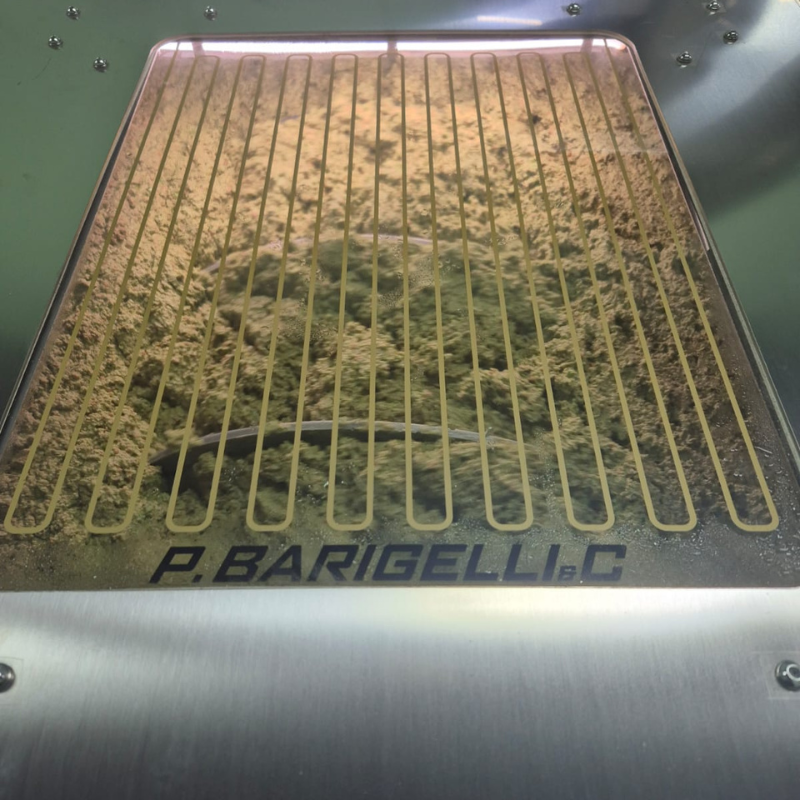

Barigelli Malaxing tank showing olive paste during the malaxation phase. The transparent inspection lid allows operators to monitor flow and sediment removal, ensuring consistent oil purity before final separation.

Barigelli transparent sight chamber showing paste flow during malaxation. The precision assembly allows real-time visual monitoring of paste flow.

Barigelli multi tank malaxing facilitating automatic paste transfer with solenoids.

Barigelli’s complete olive oil processing lines integrate every stage of production into a single automated system. From olive crushing to oil clarification, each unit ensures precision control, continuous flow, and consistent extraction results tailored to the producer’s scale.

A fully installed Barigelli line featuring the CA 510 HRY horizontal decanter and automated control system. This configuration offers real-time process monitoring, stable separation, and high extraction efficiency within a compact plant layout.

A series of mobile Barigelli units designed for flexible deployment in field or facility operations. Available in multiple capacities (6, 25, and 80 m³/h), these compact systems provide full olive oil extraction and clarification capability on-site for portable or remote production environments.

|

Type |

Decanter Type | Working Capacity | Installed Power | Power Consumption | Water Consumption | L/hr | ||

|

|

|

Kg/hr | kW | kW | 2 Phase | 3 Phase | ||

| 6 - 10 Junior | B/D 300 | 300/500 | 22.5 | 15 | 0 | - | ||

| 20 - 25 | B/D 400 | 800/1100 | 50 | 28 | 0 | 160/250 | ||

| 35 - 45 |

B/D 400L |

1400/1800 | 50 | 34 | 0 | 160/250 | ||

| 50 - 60 |

B/D 500 |

2000/2500 | 75 | 55 | 0 | 200/350 | ||

| 70 - 95 |

B/D 500L |

3000/4000 | 90 | 75 | 0 | 250/350 | ||

| 115 - 150 |

B/D 650 |

6000/7000 | 140 | 110 | 0 | 500/700 | ||

| 150 - 200 |

B/D 650L |

7000/9000 | 170 | 125 | 0 | 700/900 | ||

|

|

|

|

|

|

|

|

||

Each Barigelli installation demonstrates efficient integration of key processing stages—crushing, malaxing, decanting, clarification, and control - within a single automated framework. The result is precise, continuous olive oil production tailored to modern operational standards. These installations reflect the reliability and scalability essential for both boutique and industrial olive oil processors.