| File | Title | File Description | Type | Section |

|---|---|---|---|---|

| BARIGELLI_DECANTER-BROCHURE.pdf | Barigelli Decanter Brochure | High Performance Decanter for Olive Oil Production | Brochures | Document |

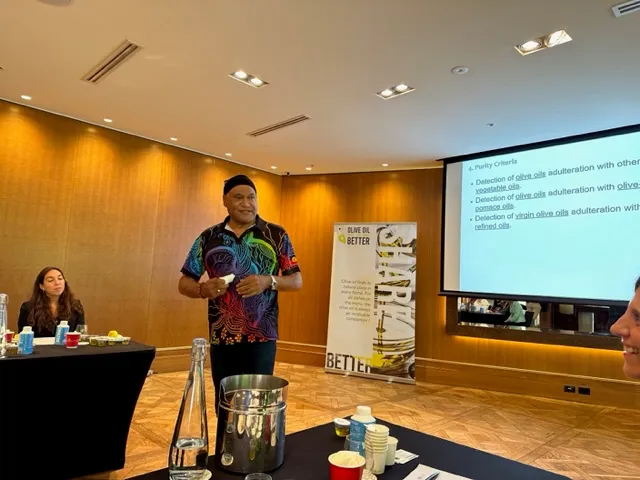

Sydney, Australia — October 20: In recent days, Sydney welcomed a delegation from the International Olive Council, comprising Maria Juarez, Head of Promotion and Economic Affairs; Dr. Imene Trabelsi Trigui, Head of Promotion; and Dr. Wenceslao Moreda, Principal Scientist and IOC specialist.

Their visit was intended to deliver a program of events in Sydney, including a two-day technical tasting workshop and a formal networking cocktail reception.

The objectives of these events were twofold. The workshop sought to strengthen collaboration between Australian growers, producers, and the International Olive Council, while the networking cocktail reception united key stakeholders — including government officials, media representatives, chefs, and producers — in a dynamic exchange. A highlight of the evening was the introduction of the newly appointed Ambassador, Mark Olive, who captivated guests with a specially crafted menu featuring Australian Indigenous ingredients such as saltbush, kangaroo, bush tomato, and native peppers, elegantly paired with a selection of Australian Extra Virgin Olive Oils.

“Advancing sustainability in olive oil production is essential to tackling climate change. We encourage producers to embrace sustainable methods that not only reduce environmental impact but also help optimize production costs. Australia’s strengthened partnership with the IOC represents a step toward a healthier and more sustainable future. Our mission is to promote greater awareness of olive oil’s benefits and sustainable practices, fostering improved and healthier consumption.” — Dr. Imene Trabelsi, Head of Promotions, International Olive Council

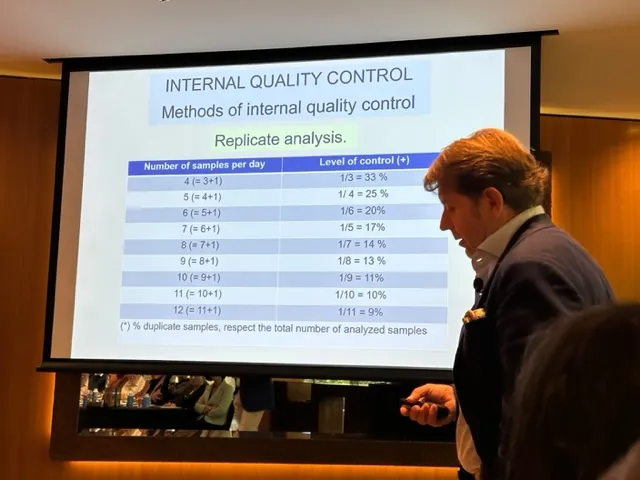

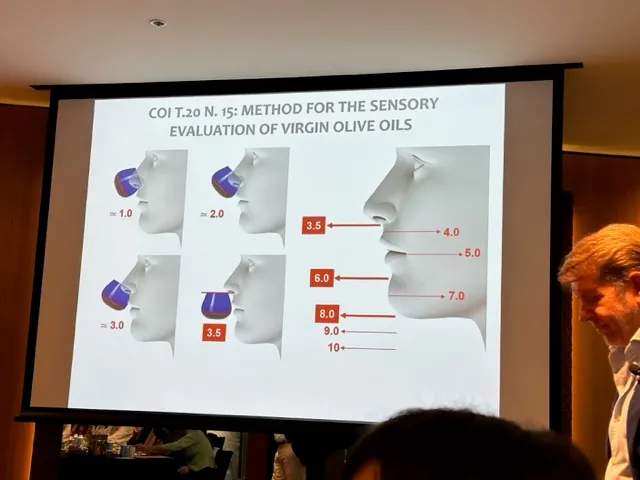

The two-day technical workshop was led by Dr. Wenceslao Moreda, an IOC specialist and Chair of the eWG of the Codex Committee on Fats and Oils (CCFO). A distinguished member of the Spanish National Research Council, Dr. Moreda holds an impressive record of over 75 research publications dating back to 1995. The opening day of the workshop focused on sensory evaluation, addressing both the physical and psychological dimensions of the organoleptic process while emphasizing the importance of proper production conditions in compliance with the rigorous standards established by the International Olive Council. The discussions provided valuable insight into the rationale behind these standards and the allowances for specific variances, reinforcing their role as the overarching global benchmark.

On the second day, the workshop focused on the quality and purity of Extra Virgin Olive Oil, examining internal quality control measures and evaluation criteria. The program concluded with an in-depth review of health-related parameters associated with olive oil, attended by nutrition experts. The breadth of technical knowledge shared proved highly valuable, offering participants a holistic understanding of the journey from production to final product from an organoleptic perspective. During the session, the IOC also announced the development of a new website dedicated to communicating the extensive health benefits of olive oil.

The International Olive Council continues to be a steadfast leader in shaping the global olive oil sector, establishing standards and fostering international collaboration essential to the industry’s advancement. As these remarkable events draw to a close, they leave a lasting impression of unity, progress, and shared commitment to the treasured ‘liquid gold’—extra virgin olive oil.

Beyond celebrating the richness and versatility of olive products, these gatherings underscored the critical importance of cooperation and knowledge exchange within the global olive community.

The International Olive Council (IOC) functions as the leading intergovernmental organization responsible for establishing the regulatory framework governing the global olive oil sector. Although Australia is not yet an official IOC member, it actively supports the organization by assisting emerging industries in adopting and applying international standards. The cooperation demonstrated during recent events underscored the IOC’s global significance and lasting impact.

The IOC also recognizes the diversity of growing conditions worldwide, which may lead to parameter variations outside of established guidelines in certain producing regions. Importantly, the IOC administers the only legally binding international standard for olive oil, reinforcing its critical role from a legislative and regulatory perspective. Complementing this, the Australian Olive Oil Association (AOOA) is acknowledged for its collaborative work with the IOC, further highlighting the importance of sustained international cooperation within the sector.

IOC Membership Process

The International Olive Council maintains strict criteria for membership. Participation is reserved exclusively for governments or international organizations empowered to negotiate, conclude, and implement international agreements, particularly those relating to commodities.

When a country seeks to join the IOC, its government must formally apply to the Council of Members, typically through its Ministry of Foreign Affairs, another relevant ministry, or its Embassy in Spain. The Council then reviews the application, establishes terms and conditions of accession — including financial contributions to the IOC budget — and sets a deadline for depositing the instrument of accession with the Secretary-General of the United Nations in New York, who serves as the official depository of the Agreement.

Upon successful deposition, the applicant nation becomes a full IOC Member. Private companies and individuals are not eligible for membership. Additionally, all European Union Member States are automatically represented in the IOC through the EU’s membership, without the need for separate applications.

In Australia’s case, stronger collaboration between national associations, government agencies, and the IOC will be essential for achieving closer alignment with international standards. Leadership from within the Australian olive oil industry itself will be critical in driving forward discussions on potential membership.

IOC Health Website

The IOC has recently launched a new website serving as a comprehensive reference hub on olive oil and health.

IOC Standards, Methods, and Guidelines

The IOC continues to provide the latest updates on trade standards for olive oil and table olives, as well as official testing protocols, sensory (organoleptic) assessment methods, and quality management practices.

OLIVE OIL PROCESSING MACHINERY

Barigelli olive oil machinery installations detail the complete journey from fruit preparation to final oil extraction. Each installation shows how individual components-crushers, malaxers, decanters, and clarification systems - work in synchrony to deliver consistent, high-quality olive oil. The following sections summarise each functional stage of the production line, referencing installation examples.

This installation combines olive crushing and paste malaxing in a compact continuous system. The crusher prepares the olive paste uniformly before transfer to the malaxing tanks, where controlled mixing optimises oil separation. Integrated control settings manage paste temperature, timing, and batch flow to maximise extraction efficiency.

Image: Vertiical Separator with Stand, Malaxing Unit with Crusher, Decanter & Control Panel all connected with raceway.

This installation showcases the Barigelli BVD 6-10 olive oil extraction system equipped with an integrated control panel. The setup includes a crusher, malaxing system, and decanter, designed for continuous olive oil processing. The control panel allows operators to manage temperature, timing, and extraction parameters for optimal oil yield and quality.

Barigelli stainless steel vertical separator in operation, showcasing freshly extracted olive oil flowing smoothly from the outlet into the collection tank. The design ensures efficient liquid separation of oil while preserving aroma, colour, and quality of extra virgin olive oil.

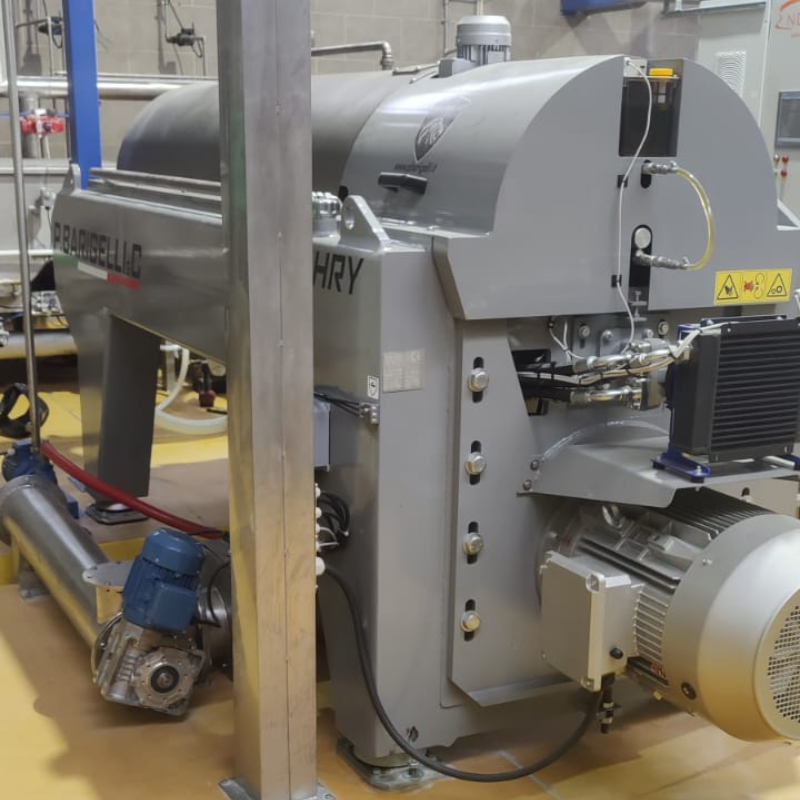

Barigelli’s high-capacity decanter systems designed to separate oil, water, and solids in a single continuous process. The horizontal design ensures high separation efficiency, reduced energy consumption, and easy maintenance access for operators.

Barigelli Early Decanter Models and First Olive Oil Plant

Barigelli’s pioneering olive oil extraction technology - from the early B/D 400 (1995) and B/D 500 (1998) decanters to the B/DF 400H hydraulic version and the first complete olive oil plant (1998). These models mark the foundation of Barigelli’s innovation in continuous olive oil processing systems.

Barigelli Decanter and Mobile Extraction Units (2005 - 2009)

Barigelli’s advanced range of decanters and mobile olive oil extraction units developed between 2005 and 2009. The models include B/DF 125 (2007), B/DF 800H (2005), and B/DF 650 XLH (2009), alongside mobile versions such as the B/DF 125H (2008) and B/DF 400LH (2007). These systems represent a leap in continuous extraction technology, combining high efficiency, portability, and precision oil separation.

Barigelli 4.50 HRY olive oil extraction setup featuring stainless steel decanters, pumps, and separator units. The continuous line integrates crushing, malaxing, decanting, and final clarification, designed for high-capacity and consistent extra virgin olive oil production.

Barigelli CA 5.10 HRY decanter, a high-efficiency centrifuge designed for large-scale olive oil extraction. Built with precision stainless steel, the system separates oil, water, and solids in a continuous process, ensuring maximum yield and superior oil quality.

Different malaxing setups can be offered in a linear system, stacked or as a bank setup.

Barigelli Olive Oil Processing Installation

Barigelli Olive Oil Processing Installation on working

Oil clarification are critical steps that can help to maintain the purity, stability, and quality of extra virgin olive oil. Once oil has been separated in the decanter, it still contains microscopic solids, waxes, and water traces. Vertical separators separate unwanted parts to minimise fermentation and cloudiness, ensuring that the oil remains bright, aromatic, and longer-lasting. Barigelli systems feature stainless-steel food-grade modules integrated directly into the processing line, allowing continuous operation without halting production or creating bottlenecks. Their modular construction supports single or multi-stage malaxation.

Barigelli stainless-steel feed system with inline sight-glass valves and transparent inspection panels. Designed for continuous olive oil feed.

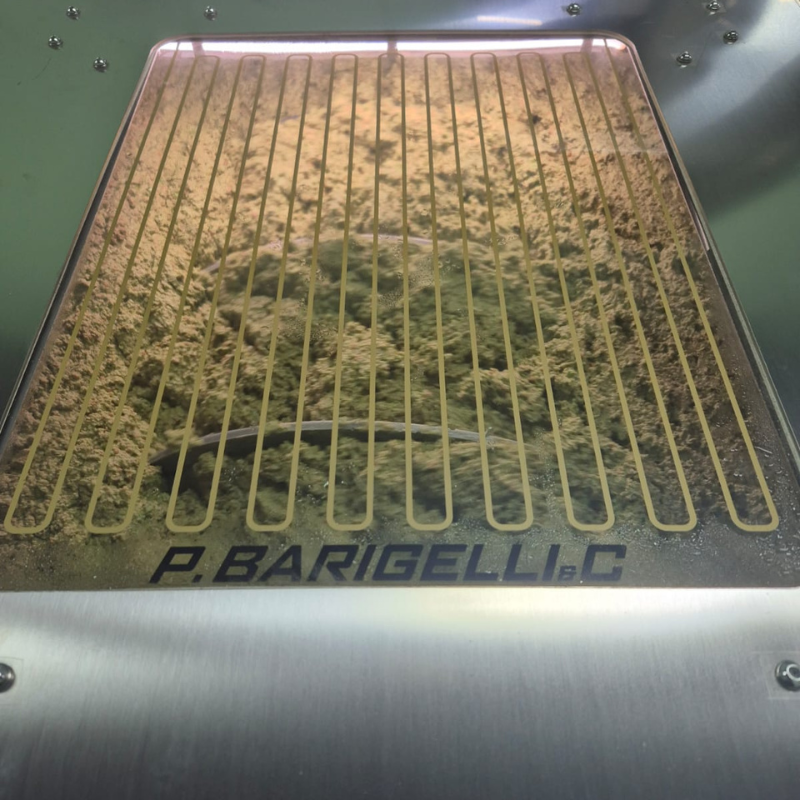

Barigelli Malaxing tank showing olive paste during the malaxation phase. The transparent inspection lid allows operators to monitor flow and sediment removal, ensuring consistent oil purity before final separation.

Barigelli transparent sight chamber showing paste flow during malaxation. The precision assembly allows real-time visual monitoring of paste flow.

Barigelli multi tank malaxing facilitating automatic paste transfer with solenoids.

Barigelli’s complete olive oil processing lines integrate every stage of production into a single automated system. From olive crushing to oil clarification, each unit ensures precision control, continuous flow, and consistent extraction results tailored to the producer’s scale.

A fully installed Barigelli line featuring the CA 510 HRY horizontal decanter and automated control system. This configuration offers real-time process monitoring, stable separation, and high extraction efficiency within a compact plant layout.

A series of mobile Barigelli units designed for flexible deployment in field or facility operations. Available in multiple capacities (6, 25, and 80 m³/h), these compact systems provide full olive oil extraction and clarification capability on-site for portable or remote production environments.

|

Type |

Decanter Type | Working Capacity | Installed Power | Power Consumption | Water Consumption | L/hr | ||

|

|

|

Kg/hr | kW | kW | 2 Phase | 3 Phase | ||

| 6 - 10 Junior | B/D 300 | 300/500 | 22.5 | 15 | 0 | - | ||

| 20 - 25 | B/D 400 | 800/1100 | 50 | 28 | 0 | 160/250 | ||

| 35 - 45 |

B/D 400L |

1400/1800 | 50 | 34 | 0 | 160/250 | ||

| 50 - 60 |

B/D 500 |

2000/2500 | 75 | 55 | 0 | 200/350 | ||

| 70 - 95 |

B/D 500L |

3000/4000 | 90 | 75 | 0 | 250/350 | ||

| 115 - 150 |

B/D 650 |

6000/7000 | 140 | 110 | 0 | 500/700 | ||

| 150 - 200 |

B/D 650L |

7000/9000 | 170 | 125 | 0 | 700/900 | ||

|

|

|

|

|

|

|

|

||

Each Barigelli installation demonstrates efficient integration of key processing stages—crushing, malaxing, decanting, clarification, and control - within a single automated framework. The result is precise, continuous olive oil production tailored to modern operational standards. These installations reflect the reliability and scalability essential for both boutique and industrial olive oil processors.