| Specification | Value |

|---|---|

| Bowl Diameter | 650 mm |

| Slenderness Ratio | 4.00 |

| Centrifugal Force | ≈ 2,500 g |

| Hydraulic Flow (Capacity) | 110 m³/h |

| Length × Width × Height (mm) | 5,000 × 1,480 × 1,870 |

| Weight | 6,400 kg |

| Material – Shell | Carbon Steel |

| Material – Discharge & Auger | AISI 304 Stainless Steel |

| Drum Material | X3 CrNiMo 13.4 Alloy Steel |

| Drive System | Hydraulic Clutch & Cycle Reduction Unit |

| Bearings | SKF / RHP High-Load Precision Type |

| Operation Mode | Continuous Automatic Separation |

| Manufacturer | Barigelli Engineering – Italy |

For decades, engineers have envisioned a compact, efficient, and hygienic machine capable of producing extra virgin olive oil on-site. That dream is now a reality. Modern technology has made it possible for growers to produce their own extra virgin olive oil using a self-contained, economical system that delivers professional-grade results.

This innovation empowers Australian olive growers to add value to their produce - from picking and processing to bottling - using their own equipment. Beyond personal production, it opens the door for entrepreneurs to establish contract processing businesses, pressing olives for others with ease and precision.

Centrifugal extraction technology was a revolution in the olive oil industry. It replaced older, labour-intensive systems with continuous-flow designs that offered greater hygiene, improved labour efficiency, and higher capacity. These advances quickly made the traditional hydraulic press obsolete.

In the past, Mediterranean growers would haul heavy sacks of freshly picked olives - often already fermenting - to local mills. There, they would join the community in spreading the crushed paste onto mats and watching as hydraulic presses squeezed out the golden liquid. It was a scene rich with tradition, aroma, and anticipation.

Today, the romance of that process has given way to something far more refined. Continuous-flow extraction plants now accept fruit within 48 hours of harvest to prevent overheating and fermentation. Delivered in ventilated plastic crates, the olives enter stainless steel systems that maintain strict hygiene standards, emerging as pure, high-quality oil. The process may lack the old-world spectacle, but it ensures superior product consistency and safety.

Currently, hundreds of Australian processors are already achieving outstanding results with Oliomio systems, producing exquisite extra virgin olive oil from their own fruit. True to its name - Oliomio, meaning “My Oil” - this technology gives growers full control over every stage of production, from fruit to finished bottle.

Each Genuine Oliomio machine is backed by excellent technical support provided by The Olive Centre, the exclusive Australian distributor. The Olive Centre offers on-site installation and comprehensive after-sales care to ensure growers get the best possible results from their investment.

The rise of accessible, high-performance extraction equipment marks a turning point for the Australian olive industry. Growers can now operate with greater independence, reduce processing costs, and elevate the quality of their oil - all while maintaining the authenticity and freshness that consumers demand.

As The Olive Centre team notes, this innovation was made possible thanks to the enthusiasm and vision of Australian olive growers themselves. Their commitment to excellence has driven this exciting step forward in local production.

Whether you’re looking to press your own olives or launch a boutique processing service, Oliomio offers a practical, proven pathway to success. For more information and a free information booklet, contact The Olive Centre - and take the first step toward making “My Oil” truly your own.

See More: Oliomio Machinery

OLIVE OIL PROCESSING MACHINERY

Barigelli olive oil machinery installations detail the complete journey from fruit preparation to final oil extraction. Each installation shows how individual components-crushers, malaxers, decanters, and clarification systems - work in synchrony to deliver consistent, high-quality olive oil. The following sections summarise each functional stage of the production line, referencing installation examples.

This installation combines olive crushing and paste malaxing in a compact continuous system. The crusher prepares the olive paste uniformly before transfer to the malaxing tanks, where controlled mixing optimises oil separation. Integrated control settings manage paste temperature, timing, and batch flow to maximise extraction efficiency.

Image: Vertiical Separator with Stand, Malaxing Unit with Crusher, Decanter & Control Panel all connected with raceway.

This installation showcases the Barigelli BVD 6-10 olive oil extraction system equipped with an integrated control panel. The setup includes a crusher, malaxing system, and decanter, designed for continuous olive oil processing. The control panel allows operators to manage temperature, timing, and extraction parameters for optimal oil yield and quality.

Barigelli stainless steel vertical separator in operation, showcasing freshly extracted olive oil flowing smoothly from the outlet into the collection tank. The design ensures efficient liquid separation of oil while preserving aroma, colour, and quality of extra virgin olive oil.

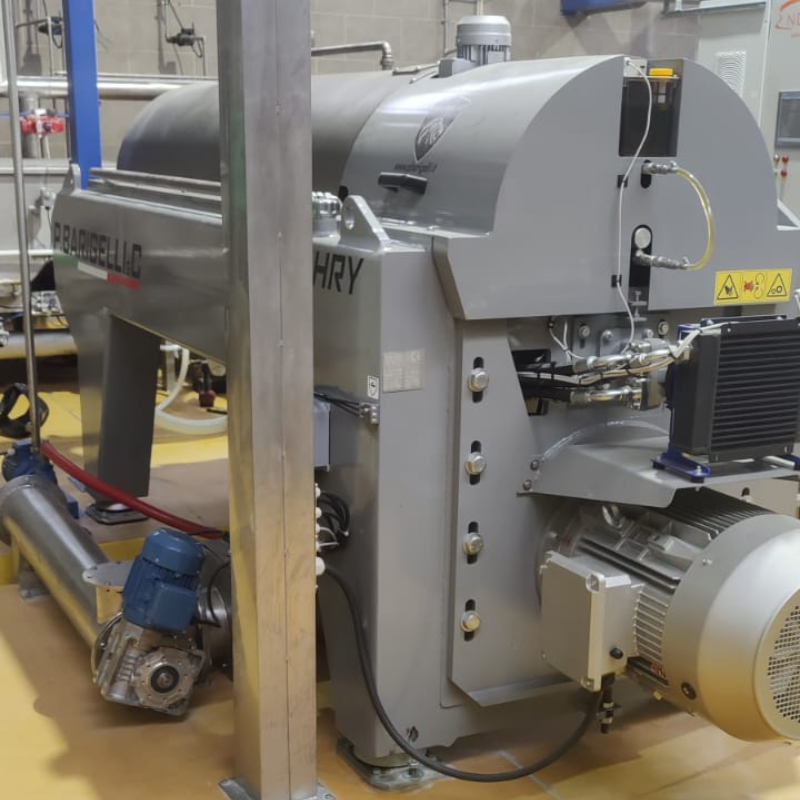

Barigelli’s high-capacity decanter systems designed to separate oil, water, and solids in a single continuous process. The horizontal design ensures high separation efficiency, reduced energy consumption, and easy maintenance access for operators.

Barigelli Early Decanter Models and First Olive Oil Plant

Barigelli’s pioneering olive oil extraction technology - from the early B/D 400 (1995) and B/D 500 (1998) decanters to the B/DF 400H hydraulic version and the first complete olive oil plant (1998). These models mark the foundation of Barigelli’s innovation in continuous olive oil processing systems.

Barigelli Decanter and Mobile Extraction Units (2005 - 2009)

Barigelli’s advanced range of decanters and mobile olive oil extraction units developed between 2005 and 2009. The models include B/DF 125 (2007), B/DF 800H (2005), and B/DF 650 XLH (2009), alongside mobile versions such as the B/DF 125H (2008) and B/DF 400LH (2007). These systems represent a leap in continuous extraction technology, combining high efficiency, portability, and precision oil separation.

Barigelli 4.50 HRY olive oil extraction setup featuring stainless steel decanters, pumps, and separator units. The continuous line integrates crushing, malaxing, decanting, and final clarification, designed for high-capacity and consistent extra virgin olive oil production.

Barigelli CA 5.10 HRY decanter, a high-efficiency centrifuge designed for large-scale olive oil extraction. Built with precision stainless steel, the system separates oil, water, and solids in a continuous process, ensuring maximum yield and superior oil quality.

Different malaxing setups can be offered in a linear system, stacked or as a bank setup.

Barigelli Olive Oil Processing Installation

Barigelli Olive Oil Processing Installation on working

Oil clarification are critical steps that can help to maintain the purity, stability, and quality of extra virgin olive oil. Once oil has been separated in the decanter, it still contains microscopic solids, waxes, and water traces. Vertical separators separate unwanted parts to minimise fermentation and cloudiness, ensuring that the oil remains bright, aromatic, and longer-lasting. Barigelli systems feature stainless-steel food-grade modules integrated directly into the processing line, allowing continuous operation without halting production or creating bottlenecks. Their modular construction supports single or multi-stage malaxation.

Barigelli stainless-steel feed system with inline sight-glass valves and transparent inspection panels. Designed for continuous olive oil feed.

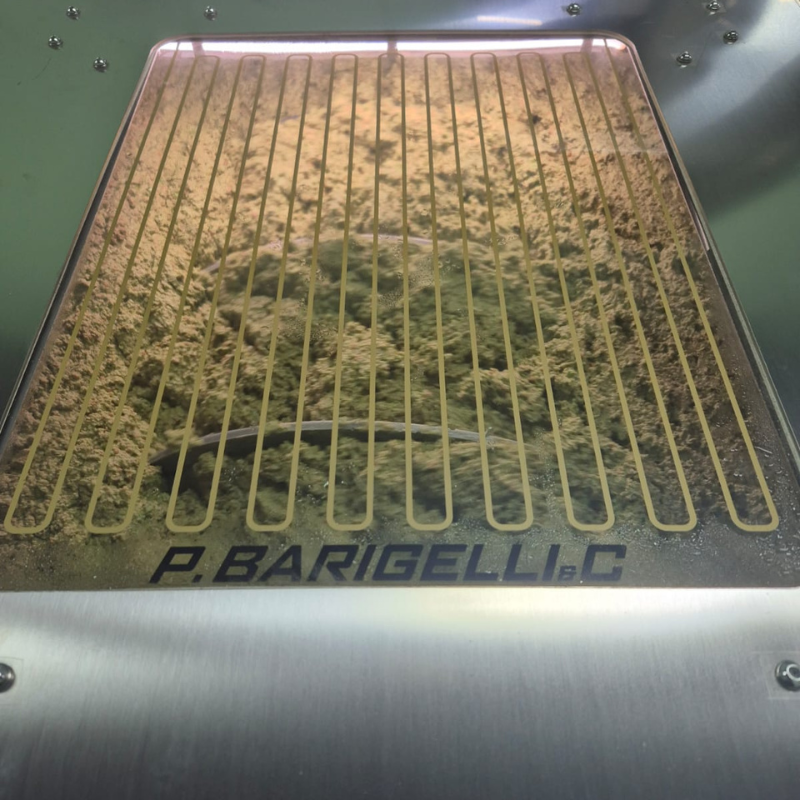

Barigelli Malaxing tank showing olive paste during the malaxation phase. The transparent inspection lid allows operators to monitor flow and sediment removal, ensuring consistent oil purity before final separation.

Barigelli transparent sight chamber showing paste flow during malaxation. The precision assembly allows real-time visual monitoring of paste flow.

Barigelli multi tank malaxing facilitating automatic paste transfer with solenoids.

Barigelli’s complete olive oil processing lines integrate every stage of production into a single automated system. From olive crushing to oil clarification, each unit ensures precision control, continuous flow, and consistent extraction results tailored to the producer’s scale.

A fully installed Barigelli line featuring the CA 510 HRY horizontal decanter and automated control system. This configuration offers real-time process monitoring, stable separation, and high extraction efficiency within a compact plant layout.

A series of mobile Barigelli units designed for flexible deployment in field or facility operations. Available in multiple capacities (6, 25, and 80 m³/h), these compact systems provide full olive oil extraction and clarification capability on-site for portable or remote production environments.

|

Type |

Decanter Type | Working Capacity | Installed Power | Power Consumption | Water Consumption | L/hr | ||

|

|

|

Kg/hr | kW | kW | 2 Phase | 3 Phase | ||

| 6 - 10 Junior | B/D 300 | 300/500 | 22.5 | 15 | 0 | - | ||

| 20 - 25 | B/D 400 | 800/1100 | 50 | 28 | 0 | 160/250 | ||

| 35 - 45 |

B/D 400L |

1400/1800 | 50 | 34 | 0 | 160/250 | ||

| 50 - 60 |

B/D 500 |

2000/2500 | 75 | 55 | 0 | 200/350 | ||

| 70 - 95 |

B/D 500L |

3000/4000 | 90 | 75 | 0 | 250/350 | ||

| 115 - 150 |

B/D 650 |

6000/7000 | 140 | 110 | 0 | 500/700 | ||

| 150 - 200 |

B/D 650L |

7000/9000 | 170 | 125 | 0 | 700/900 | ||

|

|

|

|

|

|

|

|

||

Each Barigelli installation demonstrates efficient integration of key processing stages—crushing, malaxing, decanting, clarification, and control - within a single automated framework. The result is precise, continuous olive oil production tailored to modern operational standards. These installations reflect the reliability and scalability essential for both boutique and industrial olive oil processors.

Modern extra virgin olive oil (EVOO) production relies on continuous centrifugal extraction, which has largely replaced traditional presses. In a continuous system, olives are cleaned, crushed into paste, and then malaxed (gently mixed) before a horizontal decanter centrifuge separates oil from water and solids. This process is far more efficient and hygienic than the old press-and-mat method, which is now considered obsolete. Key quality factors include processing fruit quickly to avoid fermentation, maintaining low temperatures during malaxation, and minimising exposure to oxygen. For example, transporting olives in ventilated crates and crushing/milling within 24-48 hours of harvest helps prevent heat buildup and unwanted fermentation that could spoil flavour. Cleaning and de-leafing the fruit before crushing is also critical - removing leaves, dirt, and debris ensures no off-flavours or contaminants make it into the oil. Mordern mills typically incorporate washing and leaf-removal steps for this reason.

Temperature control is paramount during extraction. EVOO is generally produced under “cold-press” conditions, meaning malaxation is kept around ≤27 °C to preserve aromatic compounds and polyphenols. Longer malaxation times or higher temperatures can increase yield but will reduce polyphenol content and flavour freshness. Recent research confirms that malaxation time and temperature must be optimised per cultivar e.g., one study found that extending malaxation from 15 to 90 minutes caused polyphenols to drop by up to 70%. In Australian groves, where harvest season temperatures can be high, processors often monitor paste temperature closely and may use heat exchangers or vacuum conditions to control it. Shorter malaxation (20-40 minutes) at moderate temperatures is commonly employed to balance oil yield with quality retention. Equally important is timing from harvest - olives allowed to sit too long (especially in warm conditions) will start fermenting. Using shallow, well-ventilated bins and milling within a day of picking is recommended to keep olives cool and intact. Big Horn Olive Oil in USA, for instance, emphasises rapid processing: they cold-press olives within 2 hours of harvest to “lock in freshness and antioxidants,” drastically reducing oxidation time in between. Such practices help Australian producers achieve long shelf life (18 - 24 months) and vibrant flavour in their EVOO whereas Cockatoo Grove has a Midnight EVOO where they pick and press in the cool of the night.

Ongoing research in Australia has highlighted how harvest timing and orchard factors influence oil quality. As olives mature on the tree, oil yield rises, but phenolic compounds (antioxidants) tend to drop. In field trials across New South Wales and Victoria, early-harvest olives produced oils with higher polyphenol content and longer shelf stability, whereas late-picked fruit gave more mellow oils with lower antioxidant levels. Free fatty acidity and peroxide (rancidity indicators) remained low until fruit became overripe, but antioxidant-rich components like tocopherols and polyphenols decreased as the fruit matured, leading to reduced oxidative stability in late-season oils. Australian producers must therefore balance quantity vs quality: an early pick yields robust, pungent oils rich in healthful polyphenols, while a later pick yields more volume with milder taste. The table below (adapted from industry data) illustrates this trade-off:

| Harvest Time | Oil Yield (% by weight) | Flavor Profile | Antioxidant Level |

|---|---|---|---|

| Early (greener fruit) | ~12-16% (lower) | Green, grassy, intensely fruity; pronounced bitterness & pungency | High (rich in polyphenols) |

| Mid-Season | ~15-18% (moderate) | Balanced fruitiness; moderate pepperiness | Moderate |

| Late (ripe fruit) | ~20-28% (higher) | Mild, buttery, nutty; low bitterness/pungency | Lower (fewer polyphenols) |

Other local research has examined irrigation effects on oil quality. Water-stressed olive trees (common in Australian summers) often produce smaller, more bitter fruit with higher polyphenol content, whereas heavily irrigated trees yield plumper olives with diluted phenolics but higher total oil output. For example, a study found that deficit-irrigated trees had the highest polyphenol levels (and earlier fruit ripening) in dry years, while fully irrigated trees gave greater oil yields at the cost of some phenolic concentration. These findings underscore that post-harvest decisions (when to pick, how to handle fruit before milling/crushing) are just as crucial as the milling technology itself. Cutting-edge extraction equipment can maximise quality potential, but growers must still deliver quality olives to the mill and process them with urgency to produce premium Australian EVOO.

MORI-TEM offers a spectrum of Oliomio mills to suit different scales, from artisanal boutique producers up to small commercial cooperatives. All share the principles above, but with varying throughputs and degrees of automation. Below is an overview of the current Oliomio lineup and its characteristics:

To summarise the small-to-medium Oliomio models discussed above, the table below compares their capacities and key features:

| Oliomio Model | Throughput | Key Features | Typical Application |

|---|---|---|---|

| Spremoliva C30 | 30-40 kg/hour | Batch malaxer (discontinuous); basic mini-press setup; no built-in heating or automation | Hobbyists, micro-batch or lab use (older design) |

| Frantoino Bio | ~50-60 kg/hour | Continuous 2-phase system; single malaxer; simple controls; single-phase power; adjustable decanter nozzles | Boutique farms, artisanal producers, pilot plants |

| Oliomio 80 Plus | ~70-80 kg/hour | Continuous flow; horizontal malaxer with heating & temperature display; inverter speed control; basic CIP wash kit | Small farms (~0.5-1 ton/day harvest); estate olive groves |

| Oliomio Gold | ~90-100 kg/hour | Enhanced automation (auto malaxer & drum washing, variable-speed feed auger)waste pump included; single or 3-phase | Medium farms (~0.8 ton/day); premium boutique mills needing labour-saving features |

| Oliomio Profy 200 | ~150-200 kg/hour | Dual malaxers for semi-continuous processing; heavy-duty crusher; closed/vacuum malaxing; full automation; waste pump | Cooperative regional mills; small commercial processors (~1.5-2 ton/day) |

Table: Comparison of select Oliomio continuous mill models (MORI-TEM). All feature two-phase extraction, stainless steel construction, and integrated crushers and decanters; higher models add more automation and capacity. Note how the traditional press is absent - even the smallest Oliomio brings modern centrifugal extraction to the farm, highlighting the leap in technology from the old press or “monoblocco” mills of past decades.

For producers scaling beyond the monobloc units, MORI-TEM offers modular olive mill installations that handle larger throughputs while prioritising quality. These systems - marketed under names like Sintesi, Forma, Cultivar, and TecnoTEM Oliomio Sintesi Series - break the extraction process into separate machines (e.g., independent crusher, malaxer group(s), decanter, separator) designed to work in harmony. They introduce features like multiple malaxers for higher throughput, vacuum malaxation technology, and advanced control systems. Importantly, they still operate on the continuous two-phase principle and embody the same hygiene and automation ethos as the smaller Oliomio range. Here’s an overview of each series:

It is instructive to contrast the above Oliomio technologies with the outdated systems they have superseded - namely, the classic hydraulic press and early-generation farm mills (older “monoblocchi” units). Traditional olive presses involved grinding olives (often with stone mills) into paste, spreading that paste onto fibre mats, stacking them, and then applying tons of pressure in a press to squeeze out the oil/water mixture. This method, while romantic, had numerous drawbacks: it was labour-intensive and slow, exposed the olive paste to air for prolonged times, and was hard to keep clean. The mats and press equipment could harbour yeasts or moulds and were difficult to sanitise thoroughly. It was not uncommon for olives to begin fermenting in the interim between harvest and pressing - indeed, historical accounts describe farmers bringing sacks of olives to the mill that were “often already fermenting” by the time they were pressed. The result was oil of inconsistent quality and stability. Continuous centrifuge systems like Oliomio eliminated these problems by moving to an enclosed, stainless-steel process where olives are milled almost immediately after picking, drastically cutting the chance for fermentation or oxidation. The greater hygiene and speed of continuous extraction have improved average oil quality and made defects from processing (such as fusty or musty flavours from fermentation) much rarer in modern operations. As a report on introducing Oliomio technology in Australia noted, “centrifugal extraction…replaced older, labour-intensive systems with continuous-flow designs”, offering better hygiene, efficiency, and capacity - effectively rendering the old press method obsolete in quality-oriented production.

Early small-scale continuous mills (from the 1990s-2000s) were a huge step up from presses, but they lacked some refinements of today’s Oliomio models. For example, many older farm mills did not have automated temperature control for malaxation, nor continuous malaxer flow. The very first “Oliomio” monoblock (created by Tuscan innovator Giorgio Mori) was revolutionary for being compact and continuous, but subsequent generations have added further improvements. A comparison of features illustrates this evolution: the older Spremoliva 30 could only malax in batch mode (no simultaneous crushing while decanting) and had no heating system or temperature display on the malaxer. By contrast, an Oliomio 80 or Gold today has fully continuous malaxing with automated temperature control and readout. Earlier mills often used fixed-speed motors and one-size-fits-all settings, whereas new systems employ inverter drives and adjustable nozzles to accommodate different olive conditions (small, watery olives vs. large, fleshy ones, etc.). Another big leap is in automation: tasks like pomace removal and equipment washing, once manual, are now handled by integrated pumps and wash cycles in machines like the Gold and Profy. This not only reduces labour but also ensures more consistent cleanliness batch after batch. In terms of energy and water usage, modern two-phase decanters are also more sustainable - they eliminate the need for large volumes of dilution water required by traditional three-phase decanters (saving water and the energy to heat it) and produce a simpler waste stream (wet pomace) that can be repurposed or composted more easily than press liquor or black water from old systems.

Crucially, oil quality has improved with each technical advance. Traditional pressing often left higher sediment and water in the oil, necessitating longer settling or filtration and risking quicker oxidation. Continuous centrifugation yields cleaner oil immediately, and the lack of air contact preserves freshness. Chemical measures like peroxide value and UV stability are typically superior in oil produced by a modern continuous mill versus an old press, when starting with the same fruit. The ability to crush and extract within hours of harvest, at controlled temperatures, means free fatty acid levels stay extremely low and the positive flavour notes are maximised. Australian producers who have adopted the latest Oliomio systems consistently report better quality and consistency in their oils, even when processing smaller batches. As an example, Spring Gully Olives in Queensland upgraded to a two-phase Oliomio (150 kg/hr) and found it ideal: it allowed them to process their own crop and offer custom processing to neighbouring groves, all while producing oil that needed no further refining - “the 150 kg per hour Oliomio is an ideal capacity which allows small growers to have their own oil processed…and it leaves the oil in its natural state”. This kind of feedback underlines how modern machinery empowers even small-scale growers to achieve high extraction efficiency and premium quality that rivals the big producers.

In summary, the latest Mori-TEM Oliomio systems represent a convergence of advanced engineering and practical on-farm olive oil production. They enable professional, hygienic, and quality-focused extraction at scales from a few dozen kilograms up to several tonnes per hour. By carefully controlling each step - from fruit cleaning and crushing with minimal oxidation, to malaxation under controlled atmosphere, to efficient two-phase centrifuge separation - these machines ensure that the oil produced reflects the true potential of the olives. Australian growers using Oliomio equipment benefit not only from improved oil quality and shelf life, but also from greater independence and flexibility: they can harvest at optimal times and process immediately, rather than rushing to a distant community mill or risking fruit spoilage. The result is fresher, more flavorful extra virgin olive oil that meets the high standards of a sophisticated global market. And with the range of Oliomio models and configurations now available, producers can choose a setup tailored to their grove’s size and business model - whether it’s a one-person boutique press or a regional processing hub servicing multiple farms. The technology has truly opened a new chapter for the industry, one where tradition and innovation blend to produce the finest EVOO. Each bottle of oil pressed with these modern systems tells the story of careful harvest timing, immediate processing, and gentle extraction - a story that resonates strongly with Australia’s drive for quality and the world’s appreciation of premium extra virgin olive oil.

INDUSTRY UPDATE: AUSTRALIAN OLIVE GROWERS 2023 SEASON

“Earlier in the season, the industry was anticipating an excellent harvest,” Mr Valmorbida said. “However, persistent cold weather and rainfall during May and June, particularly across south-east Australia, have taken their toll.”

Although the Australian olive harvest is not officially recorded each year, the AOOA estimates that the 2023 season will produce between 18 and 19 million litres of olive oil from roughly 110,000 to 120,000 tonnes of olives.

This compares with last year’s output of 14–15 million litres and the record-breaking 2021 crop, which yielded 20–22 million litres of oil.

Mr Valmorbida explained that these fluctuations reflect the biennial cycle of olive production. “This is what we call an ‘on’ year for olives. While we were expecting an excellent yield earlier in the year, harvest results always depend heavily on weather conditions, and this season has been quite mixed for many growers.”

“The oil yield per tonne is noticeably lower than average due to the cooler growing period,” he added, “but the quality of the oil remains excellent because the fruit had more time to ripen gradually.”

Around the world, olive oil prices have reached record highs in Spain, Italy, and Greece, driven by a severe global shortage of olive oil. Hot temperatures, minimal rainfall during key stages of the growing season, and extended drought conditions across southern Spain have drastically reduced European output. In addition, the ongoing conflict in Ukraine has disrupted the production of vegetable and seed oils, increasing global demand for olive oil as an alternative.

In Australia, growers are currently achieving $6–$7 per litre for larger commercial volumes of olive oil, with even higher prices for export batches, premium small-lot oils, and organic extra virgin olive oil.

“With this global shortage, some of the larger Australian producers are in a strong position to export olive oil to Europe and receive competitive returns,” Mr Valmorbida said.

“While that’s encouraging news for the Australian olive oil industry, globally the sector is under pressure,” he continued. “There’s currently a 35–40 percent shortfall in available products, combined with escalating packaging costs, especially for glass and tin materials.”

“These factors, along with rising labour and energy expenses, are leading to higher retail prices for consumers,” he noted.

Mr Valmorbida concluded with a reminder to consumers: “It’s important to remember there’s no product quite like olive oil—its distinctive flavour, health benefits, and culinary versatility make it irreplaceable.”

#oliveharvest2024 #harvest2024

The Australian Olive Oil Association (AOOA) is a not-for-profit, independent organisation dedicated to promoting the quality, integrity, and fair trade of olive oil in Australia. Membership is open to olive oil producers, distributors, industry stakeholders, and related organisations.

Since 1993, AOOA has been a signatory to the International Olive Council (IOC) global quality control program. Each year, the Association coordinates independent laboratory testing of leading olive oil brands to ensure compliance with IOC standards.

In addition, the AOOA Certified Quality Seal Program upholds even stricter quality criteria, allowing AOOA-member products to distinguish themselves in both domestic and international markets.

For more information:

Jan Jacklin, General Manager, Australian Olive Oil Association gm@aooa.com.au www.aooa.com.au

Photo credit: Julia, olive grove – Kyneton Olives” by avlxyz is licensed under CC BY-SA 2.0. To view a copy of this license, visit: https://creativecommons.org/licenses/by-sa/2.0/?ref=openverse