My Shopping Cart

My Shopping Cart

| Specification | Value |

|---|---|

| Model | C/V 300 (TSV) |

| Construction | Full AISI stainless steel |

| Motor Power | 0.18 kW |

| Motor Speed | 3000 rpm |

| Working Mechanism | Vibrating sorting plate with adjustable forward speed |

| Liquid Management | Drain grid at entry point; optional stocking tank with plug |

| Side Guards | Removable guards separate sorted and rejected product |

| Height Adjustment | 4 adjustable feet + 4 rotating wheels |

| Discharge | Integrated discharge piping |

|

Harness the Power of a Barigelli DecanterFor serious commercial olive oil production with capacities of 500Kg/Hr up to 9Tonne per hour. |

| In order to obtain the optimal processing environment your selection of machinery is imperative ! Introducing Barigelli Decanter, Italian made olive oil production machinery with many options in fruit receival, washing, crushing, malaxing, separation, oil and waste handling available, making Barigelli suitable for a wide variety of processing styles. Barigelli combine unbeatable quality of materials with superior standards of design and manufacturing. Decanters are manufactured with DUPLEX stainless steel, with mant internal parts reinforced with tungsten carbide for extra strength All Barigelli systems are provided with a manufacturer's warranty. The Olive Centre can also provide technical services Australia wide for installation, training and after-sales backup on all of our machines. The high performace Barigelli decanter can be fitted with hydraulic drive for the ultimate in extraction performance. Key benefits of Barigelli Hydraulic Transmission: 1. Provides high torque regardless of the rotation speed required (important for oil recovery) 2. Allows dynamic modulation of the decanter speed via PLC. 3. Allows for immediate and secure evacuation of product in the event power is lost. (with other systems, such an event could leave the decanter partially or totally blocked, increasing the difficulty of restart) 4. The power requirements for normal operation of the centrifuge are minimised. See our facebook page here to view some of our existing installations. |

| With a Barigelli system you are getting a NEW state-of-the-art - NOT REFURBISHED! |

| "Just had my Barigelli machine delivered. I had no idea they are this good a quality. WOW, I'm impressed! " HM, VIC |

| OTHER APPLICATIONS Mobile Dewatering Plant - Press this link to view video (7.8MB) |

OLIVE OIL PROCESSING MACHINERY

Barigelli olive oil machinery installations detail the complete journey from fruit preparation to final oil extraction. Each installation shows how individual components-crushers, malaxers, decanters, and clarification systems - work in synchrony to deliver consistent, high-quality olive oil. The following sections summarise each functional stage of the production line, referencing installation examples.

This installation combines olive crushing and paste malaxing in a compact continuous system. The crusher prepares the olive paste uniformly before transfer to the malaxing tanks, where controlled mixing optimises oil separation. Integrated control settings manage paste temperature, timing, and batch flow to maximise extraction efficiency.

Image: Vertiical Separator with Stand, Malaxing Unit with Crusher, Decanter & Control Panel all connected with raceway.

This installation showcases the Barigelli BVD 6-10 olive oil extraction system equipped with an integrated control panel. The setup includes a crusher, malaxing system, and decanter, designed for continuous olive oil processing. The control panel allows operators to manage temperature, timing, and extraction parameters for optimal oil yield and quality.

Barigelli stainless steel vertical separator in operation, showcasing freshly extracted olive oil flowing smoothly from the outlet into the collection tank. The design ensures efficient liquid separation of oil while preserving aroma, colour, and quality of extra virgin olive oil.

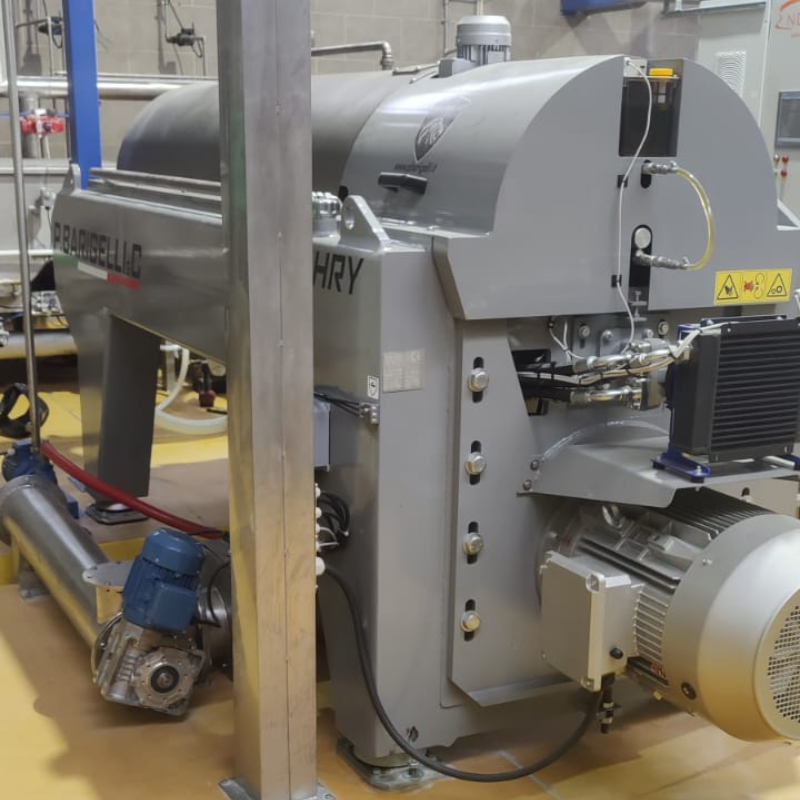

Barigelli’s high-capacity decanter systems designed to separate oil, water, and solids in a single continuous process. The horizontal design ensures high separation efficiency, reduced energy consumption, and easy maintenance access for operators.

Barigelli Early Decanter Models and First Olive Oil Plant

Barigelli’s pioneering olive oil extraction technology - from the early B/D 400 (1995) and B/D 500 (1998) decanters to the B/DF 400H hydraulic version and the first complete olive oil plant (1998). These models mark the foundation of Barigelli’s innovation in continuous olive oil processing systems.

Barigelli Decanter and Mobile Extraction Units (2005 - 2009)

Barigelli’s advanced range of decanters and mobile olive oil extraction units developed between 2005 and 2009. The models include B/DF 125 (2007), B/DF 800H (2005), and B/DF 650 XLH (2009), alongside mobile versions such as the B/DF 125H (2008) and B/DF 400LH (2007). These systems represent a leap in continuous extraction technology, combining high efficiency, portability, and precision oil separation.

Barigelli 4.50 HRY olive oil extraction setup featuring stainless steel decanters, pumps, and separator units. The continuous line integrates crushing, malaxing, decanting, and final clarification, designed for high-capacity and consistent extra virgin olive oil production.

Barigelli CA 5.10 HRY decanter, a high-efficiency centrifuge designed for large-scale olive oil extraction. Built with precision stainless steel, the system separates oil, water, and solids in a continuous process, ensuring maximum yield and superior oil quality.

Different malaxing setups can be offered in a linear system, stacked or as a bank setup.

Barigelli Olive Oil Processing Installation

Barigelli Olive Oil Processing Installation on working

Oil clarification are critical steps that can help to maintain the purity, stability, and quality of extra virgin olive oil. Once oil has been separated in the decanter, it still contains microscopic solids, waxes, and water traces. Vertical separators separate unwanted parts to minimise fermentation and cloudiness, ensuring that the oil remains bright, aromatic, and longer-lasting. Barigelli systems feature stainless-steel food-grade modules integrated directly into the processing line, allowing continuous operation without halting production or creating bottlenecks. Their modular construction supports single or multi-stage malaxation.

Barigelli stainless-steel feed system with inline sight-glass valves and transparent inspection panels. Designed for continuous olive oil feed.

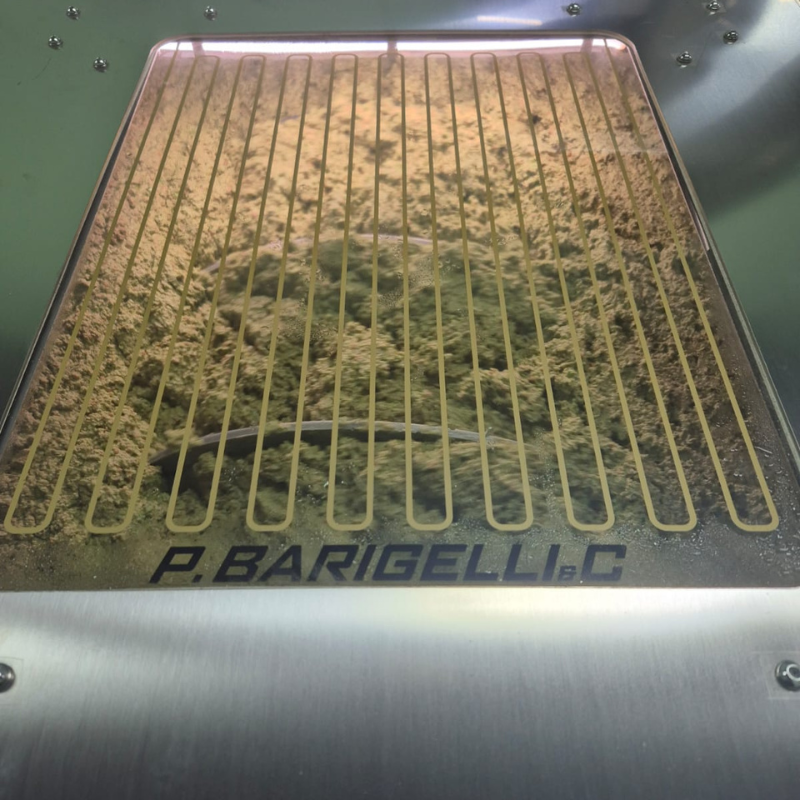

Barigelli Malaxing tank showing olive paste during the malaxation phase. The transparent inspection lid allows operators to monitor flow and sediment removal, ensuring consistent oil purity before final separation.

Barigelli transparent sight chamber showing paste flow during malaxation. The precision assembly allows real-time visual monitoring of paste flow.

Barigelli multi tank malaxing facilitating automatic paste transfer with solenoids.

Barigelli’s complete olive oil processing lines integrate every stage of production into a single automated system. From olive crushing to oil clarification, each unit ensures precision control, continuous flow, and consistent extraction results tailored to the producer’s scale.

A fully installed Barigelli line featuring the CA 510 HRY horizontal decanter and automated control system. This configuration offers real-time process monitoring, stable separation, and high extraction efficiency within a compact plant layout.

A series of mobile Barigelli units designed for flexible deployment in field or facility operations. Available in multiple capacities (6, 25, and 80 m³/h), these compact systems provide full olive oil extraction and clarification capability on-site for portable or remote production environments.

|

Type |

Decanter Type | Working Capacity | Installed Power | Power Consumption | Water Consumption | L/hr | ||

|

|

|

Kg/hr | kW | kW | 2 Phase | 3 Phase | ||

| 6 - 10 Junior | B/D 300 | 300/500 | 22.5 | 15 | 0 | - | ||

| 20 - 25 | B/D 400 | 800/1100 | 50 | 28 | 0 | 160/250 | ||

| 35 - 45 |

B/D 400L |

1400/1800 | 50 | 34 | 0 | 160/250 | ||

| 50 - 60 |

B/D 500 |

2000/2500 | 75 | 55 | 0 | 200/350 | ||

| 70 - 95 |

B/D 500L |

3000/4000 | 90 | 75 | 0 | 250/350 | ||

| 115 - 150 |

B/D 650 |

6000/7000 | 140 | 110 | 0 | 500/700 | ||

| 150 - 200 |

B/D 650L |

7000/9000 | 170 | 125 | 0 | 700/900 | ||

|

|

|

|

|

|

|

|

||

Each Barigelli installation demonstrates efficient integration of key processing stages—crushing, malaxing, decanting, clarification, and control - within a single automated framework. The result is precise, continuous olive oil production tailored to modern operational standards. These installations reflect the reliability and scalability essential for both boutique and industrial olive oil processors.

HARVESTING

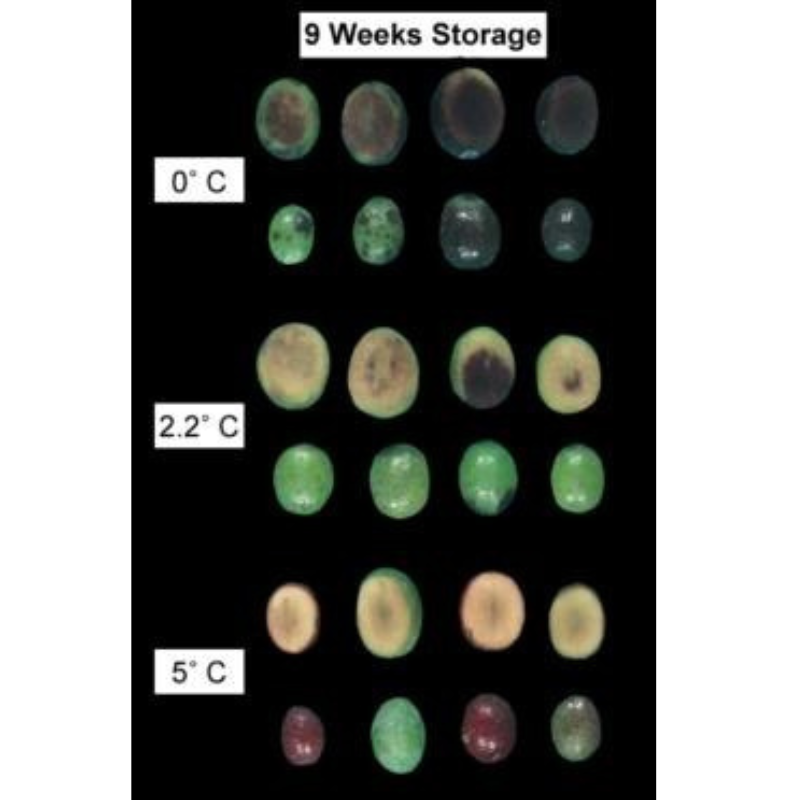

Fresh olives are highly sensitive to storage temperature and atmospheric composition before processing. While cold storage is commonly used to slow respiration and delay deterioration, inappropriate temperature or gas conditions can trigger serious physiological and physical disorders. Among these, chilling injury, carbon dioxide injury, and nailhead disorder are the most significant causes of quality loss in stored olives.

Research has shown that elevated carbon dioxide (CO₂) levels, particularly when combined with extended storage duration, substantially increase the severity of chilling-related damage. Understanding the interaction between temperature, storage time, cultivar sensitivity, and atmospheric composition is essential for growers and processors seeking to protect fruit quality prior to processing.

Chilling injury is one of the most damaging postharvest physiological disorders affecting fresh olives stored before processing. It develops when olives are exposed to temperatures below their tolerance threshold for prolonged periods.

Chilling injury can become a major cause of deterioration under the following conditions:

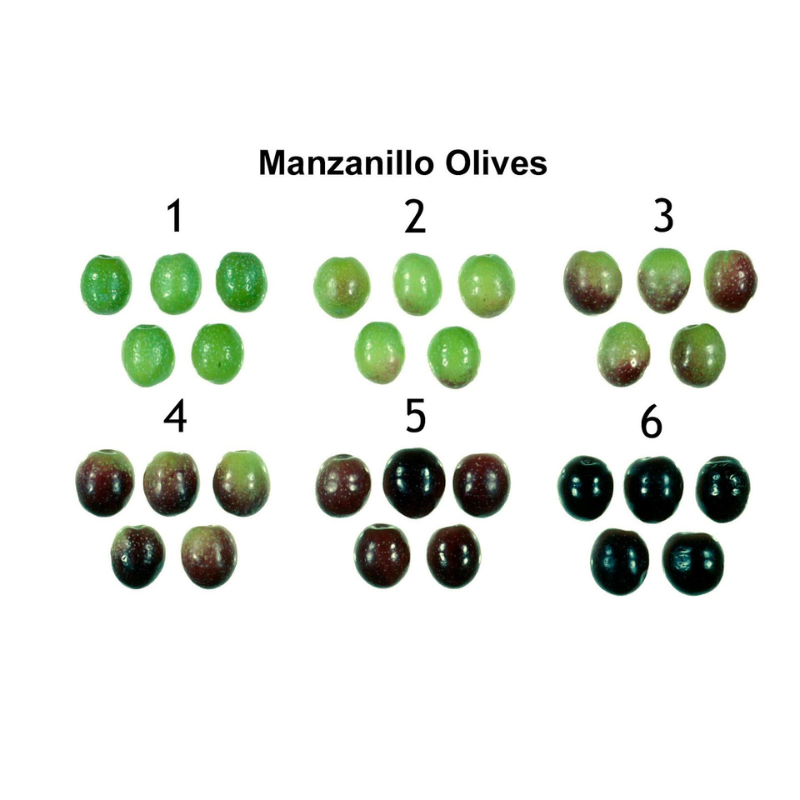

Cultivar susceptibility plays a critical role. The established order of sensitivity to chilling injury is Sevillano (most susceptible), followed by Ascolano, Manzanillo, and Mission (least susceptible).

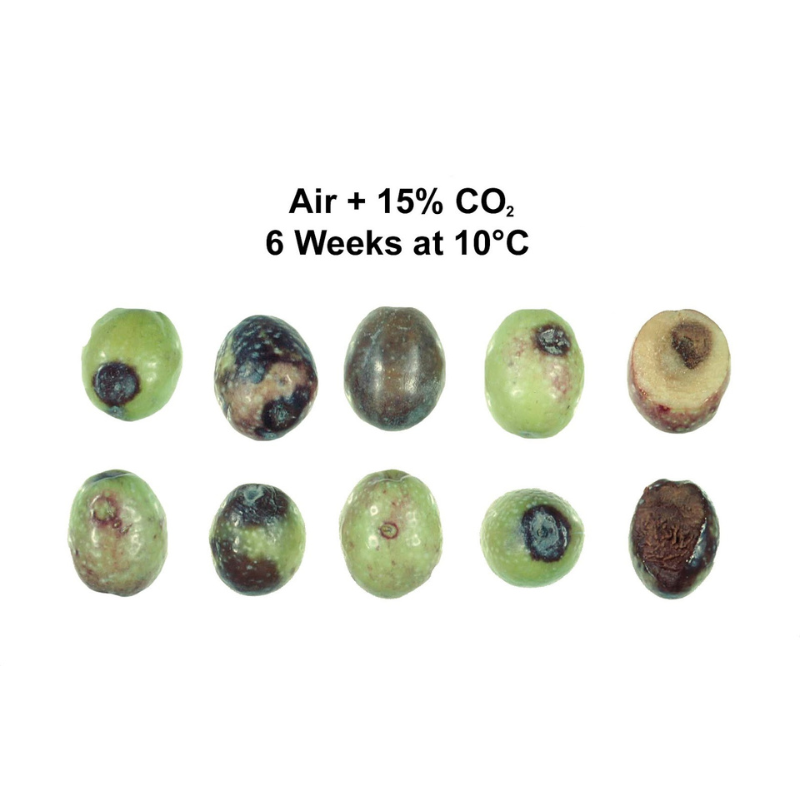

Nailhead is a physical storage disorder characterised by surface pitting and spotting of the olive skin. It results from the death and collapse of epidermal cells, creating air pockets beneath the fruit surface. These air pockets cause the characteristic pitted or hammered appearance.

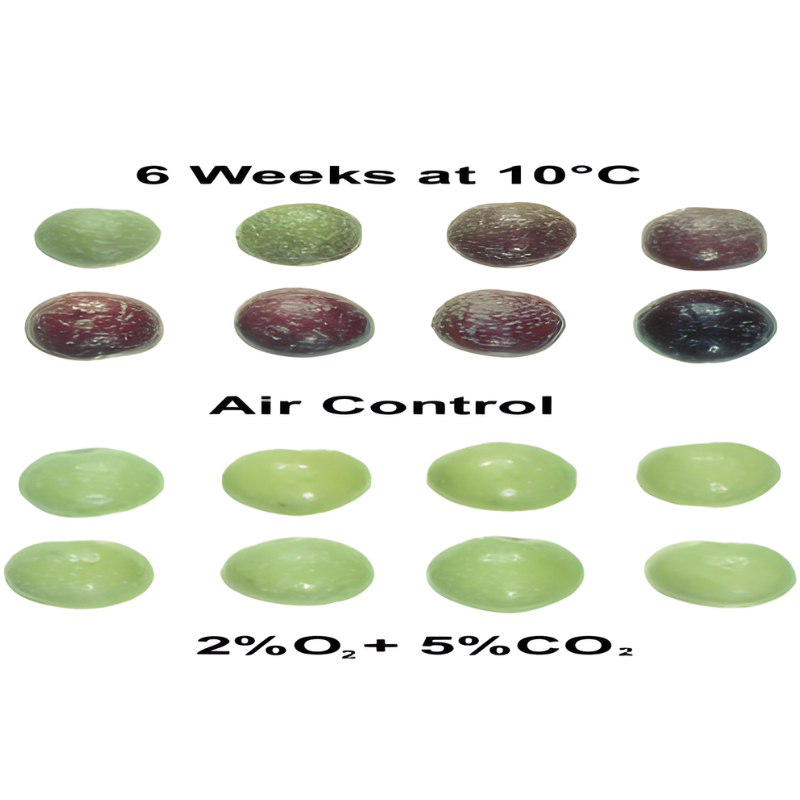

Nailhead typically develops under moderate cold storage rather than extreme chilling, with symptoms observed when olives are stored at 10°C (50°F) for six weeks or longer, or at 7.5°C (45.5°F) for twelve weeks or longer.

Although nailhead does not always involve internal browning, it significantly reduces visual quality and marketability and may increase susceptibility to secondary decay during extended storage.

Carbon dioxide injury occurs when olives are exposed to CO₂ concentrations greater than 5% for extended periods. This disorder often overlaps with chilling injury and significantly intensifies tissue damage.

Symptoms of carbon dioxide injury include internal browning similar to chilling injury, increased incidence and severity of decay, and accelerated loss of firmness and fruit integrity.

Elevated CO₂ disrupts normal respiratory metabolism, leading to cellular damage and increased vulnerability to physiological failure. While controlled atmospheres can be beneficial under carefully managed conditions, excessive CO₂ consistently results in poorer storage outcomes.

Controlled atmospheres using reduced oxygen and moderate carbon dioxide levels help maintain firmness and green skin colour when storage temperatures are kept above 5°C.

The interaction between storage temperature and atmospheric composition is critical in determining olive storage success. Elevated CO₂ levels intensify chilling injury even at temperatures that might otherwise be considered safe.

By contrast, controlled atmospheres containing approximately 2% oxygen combined with up to 5% carbon dioxide have been shown to maintain flesh firmness and preserve green skin colour when olives are stored at 5°C (41°F) or higher.

This highlights the importance of managing storage conditions as an integrated system rather than relying on temperature control alone.

Physiological and physical storage disorders can result in substantial economic losses through reduced yield, downgraded quality, and increased waste. These risks are particularly pronounced during seasons of high production when fruit must be held before processing.

Key strategies to minimise postharvest losses include avoiding storage temperatures below 5°C, limiting exposure to CO₂ concentrations above 5%, reducing storage duration wherever possible, and accounting for cultivar-specific sensitivity when planning harvest and storage logistics.

CO₂ chilling injury and related physiological disorders represent a significant challenge in fresh olive storage. The combined effects of low temperature, extended storage duration, elevated carbon dioxide levels, and cultivar susceptibility determine the severity of damage.

By maintaining appropriate temperature ranges, managing atmospheric composition carefully, and tailoring storage practices to cultivar characteristics, growers and processors can significantly reduce postharvest losses and maintain olive quality before processing.

References

Postharvest Technology Center, University of California, Davis