My Shopping Cart

My Shopping Cart

Tornado is the biggest stalk and branch remover in the range and is produced by Clemente Snc.

The working capacity of this machine is up to 20 tons per hour.

On the top of the machine there is an electric vibratory motor used for distributing the olives uniformly along the tray thus allowing the blower to separate the leaves from the olives and to eject them in a leaf bin. The olives are then separated from the branches by rotating rollers and are separated from the dirt by spirals.

At the end of the process all the waste material is collected and ejected from the machine.

| Feature | Tornado 1 | Tornado 2 |

|---|---|---|

| Model | 5CR / T | 5CR / K |

| Processing Capacity | Up to 8 t/h | Up to 20 t/h |

| Electric Motor Power | 7.5 kW | 10 kW |

| Cleaning Stages | Vibro-classifier with fan; sloped auger platform for final selection. | Vibro-classifier, twin fans, rotating drum, self-cleaning roller table, and screw-conveyor platform. |

| Dimensions (L × W × H) | 3544 × 1081 × 2545 mm | 3850 × 1900 × 4050 mm |

| Weight | 900 kg | 1800 kg |

| Material | AISI 304 Stainless Steel | AISI 304 Stainless Steel |

| Application Scale | Small to medium-size mills requiring compact operation and efficiency. | Medium to large industrial mills needing high-capacity throughput and advanced automation. |

| File | Title | File Description | Type | Section |

|---|---|---|---|---|

| Tornado-1-1_1.pdf | CLEMENTE Tornado 1 | Brochures | Document | |

| tornado-2.pdf | CLEMENTE Tornado 2 | Brochures | Document |

This breakthrough technology represents the future of olive oil processing, with developments set to redefine efficiency and production performance. The Thermospeed system has demonstrated the capability to accelerate the olive oil extraction process by up to 50%, marking a significant advancement in processing speed and throughput.

At the core of the system is an innovative design that reduces malaxation time - the critical stage where the olive paste is gently mixed before separation. The Thermospeed achieves this by pumping the olive paste through a section surrounded by a temperature-controlled tube, which can either heat or cool the paste as needed. This process optimisation helps to enhance extraction efficiency while minimising oxidation, ultimately preserving the oil’s natural quality and nutritional value.

Early trials have shown no negative effects on olive oil quality, and research is continuing over the next 12 months to further evaluate and refine the system’s performance.

This remarkable innovation could soon be integrated into olive oil processing facilities worldwide, offering producers an efficient, sustainable, and scientifically proven step forward in extra-virgin olive oil production.

MARKET INSIGHT: GLOBAL OLIVE OIL ECONOMY 2023

Introduction

The global olive oil industry in 2023 has entered uncharted territory, experiencing an extraordinary surge in olive oil prices driven by a combination of climatic and economic forces. At the centre of this crisis lies Spain’s devastating drought, which has crippled the world’s largest olive oil producer. This severe shortage has led to a dramatic contraction in olive oil supply, triggering price escalation and a corresponding decline in consumer demand. The ripple effects are being felt worldwide, reshaping the balance between producers and consumers alike. Meanwhile, Australian olive oil producers find themselves in a rare position of advantage, benefitting from unprecedented market highs. This article explores the causes, consequences, historical trends, and economic signals surrounding this remarkable global olive oil price spike.

The ongoing drought across Spain stands as the principal factor behind the current olive oil price surge. As one of the largest olive oil-producing nations globally, Spain’s drastically reduced harvest - caused by months of extreme heat and minimal rainfall - has sharply curtailed olive oil availability in both European and international markets. This has intensified supply shortages, compelling consumers to pay more for what has long been a staple Mediterranean product. The interplay of limited supply and escalating demand has magnified price volatility, reinforcing the classic supply-and-demand imbalance now driving global markets.

Incredible to see the olive groves of Jaen, Spain. This one province produces around a fifth of the *entire* global supply of olive oil

— Secunder Kermani (@SecKermani) August 31, 2023

But a combination of drought & extreme heat has left many trees badly weakened... This years harvest looks set to be the worst in living memory pic.twitter.com/QYs41eXCwC

As prices have risen steeply, the shortage of olive oil has led to a noticeable decline in consumption, particularly in Spain, where demand has reportedly dropped by around 35%. Consumers are now scaling back their purchases, finding olive oil increasingly unaffordable compared to other cooking oils. The once-steady household consumption patterns are shifting as people seek alternatives or modify their cooking habits. This contraction in domestic demand not only highlights the growing accessibility gap for consumers but also underscores the broader economic strain caused by high inflation and food price increases.

Amid the turmoil, Australian olive oil producers are experiencing a windfall. Thanks to limited global supply, Australian growers are commanding record prices exceeding AUD $8 per litre, marking the highest levels ever recorded in the nation’s olive oil industry. This lucrative period presents a rare opportunity for Australian exporters, with demand from Europe - including Spain itself - now turning toward Australian supplies. For producers Down Under, this unique reversal of roles underscores how regional climate resilience and diversified production can translate into significant financial gains when global shortages arise.

The olive oil market’s volatility is not a new phenomenon. Previous spikes occurred in 1996, 2006, and 2015, each triggered by weather-related supply constraints. Yet, the 2023 price explosion stands out as the most dramatic in recorded history -over 40% higher than any previous price peak, and roughly double the magnitude of earlier surges. This extreme escalation reflects not just climatic hardship but a clear pricing bubble forming within the market, echoing the cyclical nature of commodity pricing.

The olive oil sector has long followed cyclical pricing patterns, typically alternating between low and high price phases roughly every decade. The current surge aligns almost perfectly with the predicted start of another 10-year cycle, occurring just three years into its anticipated timeline. Furthermore, a notable correlation has been identified between the Australian Food Inflation Index and the Global Olive Oil Price Index as reported by the International Monetary Fund (IMF). This connection illustrates the deep interdependence between food commodity pricing and global economic conditions.

While the IMF’s benchmark prices are denominated in USD, for the purposes of this analysis they have been converted to AUD to track the trend relative to Australian markets. These benchmark indicators -based on the world’s largest olive oil exporters -serve as a reliable gauge of overall market direction, confirming how global shortages and inflationary pressures move in tandem.

Global olive oil prices show a recurring 10-year cycle, driven by droughts, crop shortages, and rising production costs

Global olive oil prices show a recurring 10-year cycle, driven by droughts, crop shortages, and rising production costs

From a technical analysis perspective, the Relative Strength Indicator (RSI) is often used to measure price momentum and potential overextension in markets. On recent olive oil price charts, the RSI (represented in purple) indicates that prices have once again entered overbought territory - a level seen during previous speculative phases. Historically, such readings have preceded market corrections or reversals, suggesting that the current surge may not be sustainable in the long term.

Analysts caution that as the European olive harvest begins in September and October 2023, an influx of new oil supplies could help ease prices, though the timing and extent of this correction remain uncertain. Until then, speculative trading and limited inventory continue to support inflated market values.

The record-breaking olive oil prices of 2023, primarily triggered by Spain’s drought-induced production collapse, mark a turning point for the global olive oil economy. With consumer demand declining under the pressure of soaring prices and Australian producers thriving amid the scarcity, the industry is experiencing a dramatic rebalancing. Historical precedents, cyclical trends, and market indicators all point toward a complex, transitional period defined by volatility and uncertainty.

As the world’s producers, traders, and consumers adapt to these new market dynamics, one truth remains clear: olive oil - celebrated for its taste, health benefits, and cultural significance - continues to be at the mercy of both climate change and economic cycles. Stakeholders across the value chain must remain alert, flexible, and forward-thinking as the olive oil market navigates this extraordinary phase of transformation.

Other Sources

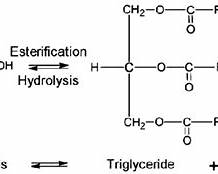

Esterification is a natural chemical reaction where free fatty acids (FFA) combine with alcohols, typically glycerol, to form esters. This process reduces the measurable acidity of the oil. While esterification can occur in the olive paste during milling, it is usually a minor contributor to quality changes compared with factors such as fruit condition, malaxation parameters, and extraction efficiency.

This diagram outlines the continuous olive oil extraction line: olives are crushed, malaxed, separated, clarified, and routed for bottling, while husk and wastewater are channelled to waste management systems.

Processing aids act physically or chemically on the olive paste. Some enhance enzyme activity, others alter pH or moisture, and a few influence esterification indirectly. Below is a breakdown of the main aids used by professional olive processors and how each relates to esterification.

Calcium carbonate is the processing aid most associated with apparent esterification effects.

Influence on esterification

Salt acts primarily on the physical structure of the paste rather than the oil chemistry.

Influence on esterification

Talc is inert and valued for its physical functionality.

Influence on esterification

Commercial enzyme blends can influence chemistry indirectly.

Influence on esterification

These clay minerals are used more for paste modification or clarification.

Influence on esterification

| Processing Aid | Impact on Esterification | Notes |

|---|---|---|

| Calcium Carbonate | Moderate … via pH shift | Can lower measured FFA but may affect flavour and oxidation |

| Salt (NaCl) | None | Improvements come from better separation, not chemical change |

| Talc | None | Purely physical aid for difficult pastes |

| Enzymes | Minor, indirect | Mostly physical… chemical breakdown of cell walls |

| Kaolin | None | Improves rheology only |

| Bentonite | None | Used for clarification rather than extraction |

Professional olive mills benefit from:

Esterification occurs when free fatty acids (FFA) in olives or olive paste react with natural alcohols—most commonly glycerol—to form esters. While this is a natural chemical reaction found in many biological systems, it usually plays only a small role during standard olive oil extraction. However, under certain processing or fruit-quality conditions, esterification can become more noticeable and can affect how acidity is interpreted during quality assessment.

Understanding when and why esterification occurs is important for mill operators, as it can influence extraction decisions, processing aid use, and the accuracy of acidity readings that determine Extra Virgin classification.

Esterification is not inherently harmful, but it becomes more noticeable when fruit quality is compromised or when additives alter the paste’s pH and reaction environment. This means that an oil’s reduced measurable acidity may not always reflect true quality improvement.

1. Higher Paste Temperatures

4. Extended Contact Time

5. Enzymatic Activity

When esterification occurs under the conditions described above, it can lower the measured FFA without actually improving the oil’s true chemical quality. This can mislead producers into thinking their processing steps or additives improved the oil, when in reality the acidity reduction was simply a chemical conversion—not a restoration of fruit integrity.

Producers who understand these mechanisms can:

In simple terms: Esterification becomes noticeable when the olive paste is warm, slightly alkaline, contains damaged fruit components, or sits too long before separation. Managing these factors helps prevent misleading acidity readings and supports genuine quality improvements.