My Shopping Cart

My Shopping Cart

OLIVE OIL PROCESSING MACHINERY

Barigelli olive oil machinery installations detail the complete journey from fruit preparation to final oil extraction. Each installation shows how individual components-crushers, malaxers, decanters, and clarification systems - work in synchrony to deliver consistent, high-quality olive oil. The following sections summarise each functional stage of the production line, referencing installation examples.

This installation combines olive crushing and paste malaxing in a compact continuous system. The crusher prepares the olive paste uniformly before transfer to the malaxing tanks, where controlled mixing optimises oil separation. Integrated control settings manage paste temperature, timing, and batch flow to maximise extraction efficiency.

Image: Vertiical Separator with Stand, Malaxing Unit with Crusher, Decanter & Control Panel all connected with raceway.

This installation showcases the Barigelli BVD 6-10 olive oil extraction system equipped with an integrated control panel. The setup includes a crusher, malaxing system, and decanter, designed for continuous olive oil processing. The control panel allows operators to manage temperature, timing, and extraction parameters for optimal oil yield and quality.

Barigelli stainless steel vertical separator in operation, showcasing freshly extracted olive oil flowing smoothly from the outlet into the collection tank. The design ensures efficient liquid separation of oil while preserving aroma, colour, and quality of extra virgin olive oil.

Barigelli’s high-capacity decanter systems designed to separate oil, water, and solids in a single continuous process. The horizontal design ensures high separation efficiency, reduced energy consumption, and easy maintenance access for operators.

Barigelli Early Decanter Models and First Olive Oil Plant

Barigelli’s pioneering olive oil extraction technology - from the early B/D 400 (1995) and B/D 500 (1998) decanters to the B/DF 400H hydraulic version and the first complete olive oil plant (1998). These models mark the foundation of Barigelli’s innovation in continuous olive oil processing systems.

Barigelli Decanter and Mobile Extraction Units (2005 - 2009)

Barigelli’s advanced range of decanters and mobile olive oil extraction units developed between 2005 and 2009. The models include B/DF 125 (2007), B/DF 800H (2005), and B/DF 650 XLH (2009), alongside mobile versions such as the B/DF 125H (2008) and B/DF 400LH (2007). These systems represent a leap in continuous extraction technology, combining high efficiency, portability, and precision oil separation.

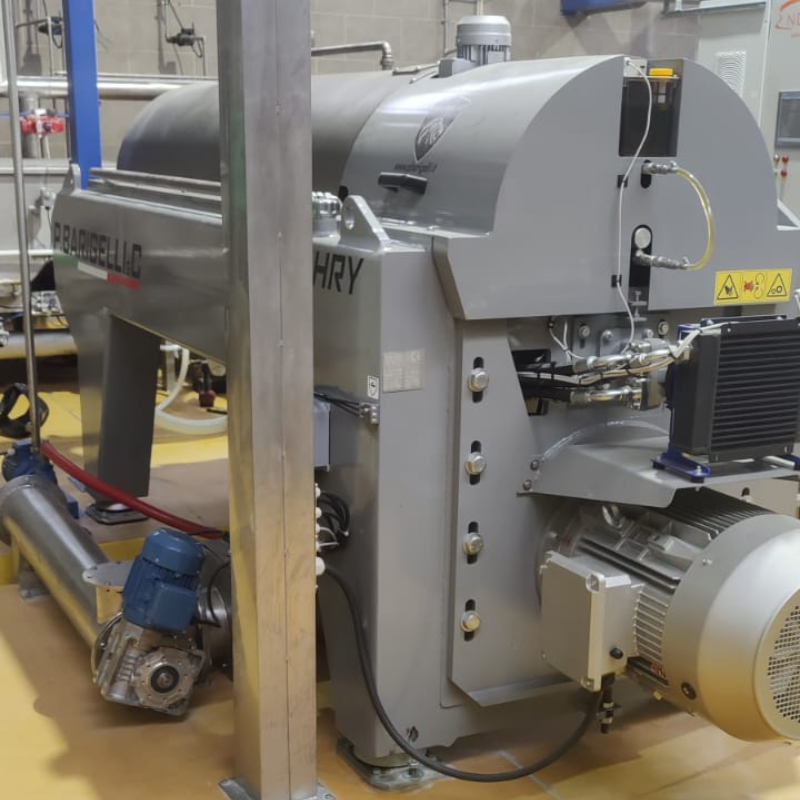

Barigelli 4.50 HRY olive oil extraction setup featuring stainless steel decanters, pumps, and separator units. The continuous line integrates crushing, malaxing, decanting, and final clarification, designed for high-capacity and consistent extra virgin olive oil production.

Barigelli CA 5.10 HRY decanter, a high-efficiency centrifuge designed for large-scale olive oil extraction. Built with precision stainless steel, the system separates oil, water, and solids in a continuous process, ensuring maximum yield and superior oil quality.

Different malaxing setups can be offered in a linear system, stacked or as a bank setup.

Barigelli Olive Oil Processing Installation

Barigelli Olive Oil Processing Installation on working

Oil clarification are critical steps that can help to maintain the purity, stability, and quality of extra virgin olive oil. Once oil has been separated in the decanter, it still contains microscopic solids, waxes, and water traces. Vertical separators separate unwanted parts to minimise fermentation and cloudiness, ensuring that the oil remains bright, aromatic, and longer-lasting. Barigelli systems feature stainless-steel food-grade modules integrated directly into the processing line, allowing continuous operation without halting production or creating bottlenecks. Their modular construction supports single or multi-stage malaxation.

Barigelli stainless-steel feed system with inline sight-glass valves and transparent inspection panels. Designed for continuous olive oil feed.

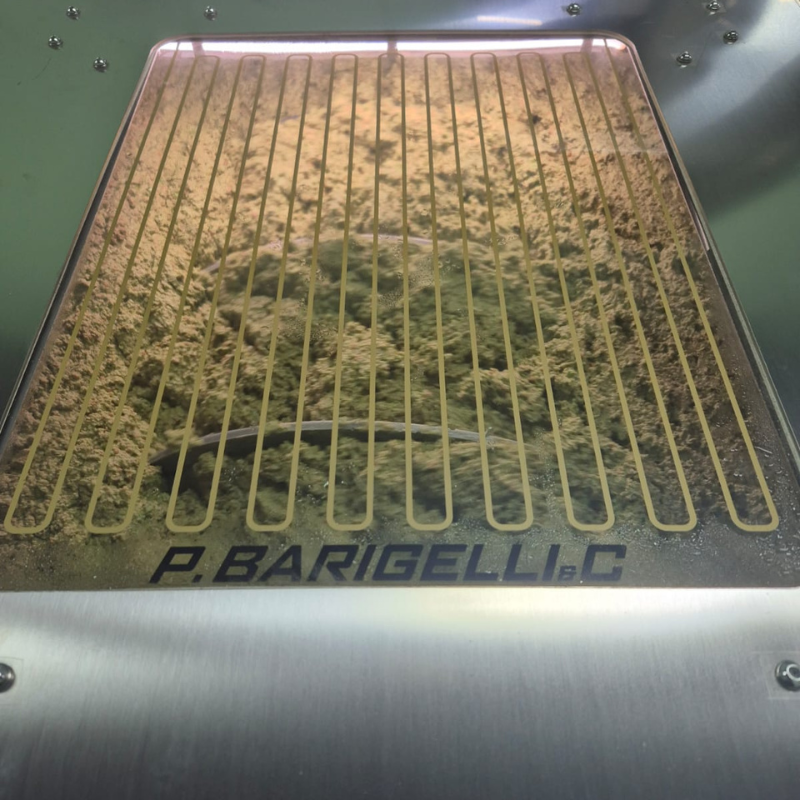

Barigelli Malaxing tank showing olive paste during the malaxation phase. The transparent inspection lid allows operators to monitor flow and sediment removal, ensuring consistent oil purity before final separation.

Barigelli transparent sight chamber showing paste flow during malaxation. The precision assembly allows real-time visual monitoring of paste flow.

Barigelli multi tank malaxing facilitating automatic paste transfer with solenoids.

Barigelli’s complete olive oil processing lines integrate every stage of production into a single automated system. From olive crushing to oil clarification, each unit ensures precision control, continuous flow, and consistent extraction results tailored to the producer’s scale.

A fully installed Barigelli line featuring the CA 510 HRY horizontal decanter and automated control system. This configuration offers real-time process monitoring, stable separation, and high extraction efficiency within a compact plant layout.

A series of mobile Barigelli units designed for flexible deployment in field or facility operations. Available in multiple capacities (6, 25, and 80 m³/h), these compact systems provide full olive oil extraction and clarification capability on-site for portable or remote production environments.

|

Type |

Decanter Type | Working Capacity | Installed Power | Power Consumption | Water Consumption | L/hr | ||

|

|

|

Kg/hr | kW | kW | 2 Phase | 3 Phase | ||

| 6 - 10 Junior | B/D 300 | 300/500 | 22.5 | 15 | 0 | - | ||

| 20 - 25 | B/D 400 | 800/1100 | 50 | 28 | 0 | 160/250 | ||

| 35 - 45 |

B/D 400L |

1400/1800 | 50 | 34 | 0 | 160/250 | ||

| 50 - 60 |

B/D 500 |

2000/2500 | 75 | 55 | 0 | 200/350 | ||

| 70 - 95 |

B/D 500L |

3000/4000 | 90 | 75 | 0 | 250/350 | ||

| 115 - 150 |

B/D 650 |

6000/7000 | 140 | 110 | 0 | 500/700 | ||

| 150 - 200 |

B/D 650L |

7000/9000 | 170 | 125 | 0 | 700/900 | ||

|

|

|

|

|

|

|

|

||

Each Barigelli installation demonstrates efficient integration of key processing stages—crushing, malaxing, decanting, clarification, and control - within a single automated framework. The result is precise, continuous olive oil production tailored to modern operational standards. These installations reflect the reliability and scalability essential for both boutique and industrial olive oil processors.

Valuing your olive oil processing machinery – from presses and decanters to tractors and harvesters – is an important task for Australian producers. Whether you’re a small boutique grove or a commercial olive operation, knowing what your equipment is worth helps with insurance, resale, and financial planning. This guide explains how to value used olive oil processing machinery (with notes on new equipment costs), covers multiple valuation methods, and offers a practical Australian context. We’ll also include example scenarios (like a decade-old olive press vs. a nearly new separator) and provide tips to maintain your gear’s value over time.

Olive oil production involves specialised machinery at harvest and processing time. Key processing equipment includes olive crushers or mills (to crush olives into paste), malaxers (which slowly mix the paste), and centrifugal decanters/separators (which separate oil from water and solids). Supporting items like pumps, olive washers, and filtration units are also part of the system. Many Australian groves also use standard farm equipment such as tractors, mechanical harvesters, pruning and spraying equipment, and irrigation systems. When assessing value, focus first on the core olive oil machinery, but remember that methods discussed here apply to your tractors, harvesters, and other farm gear as well.

Modern olive processing machinery is a significant investment. For reference, a small continuous-flow olive mill (e.g. 30 kg/hour throughput) might cost around A$20,000 new, while a large commercial plant (capable of ~1 tonne/hour) can run into the hundreds of thousands of dollars. Such figures underscore why proper valuation is essential – these assets represent major capital on the farm. Below, we outline several methods to evaluate what these machines are worth, especially as they age or when considering second-hand purchases.

Valuing used farm equipment is not an exact science – it’s often best to use multiple methods to triangulate a reasonable value. Common approaches include using depreciation schedules, comparing recent market sales, calculating value based on income or cost savings, considering insurance replacement cost, and accounting for residual (salvage) value. Each method gives a different perspective:

Depreciation is the loss in value of equipment as it ages. A simple way to estimate a used machine’s value is to start from its original cost and subtract depreciation. There are two main depreciation methods: straight-line (also called prime cost) and declining-balance (diminishing value). Straight-line depreciation assumes the asset loses value evenly over its useful life, while declining-balance depreciation assumes a higher loss in early years and less in later years.

For instance, if a small olive press was purchased new for $30,000 and has a 15-year life, straight-line depreciation would be ~6.67% per year (100/15). After 10 years (two-thirds of its life), it would be about 10 × 6.67% ≈ 66.7% depreciated. In simple terms, its book value might be roughly 33% of the original cost (around $10,000 in this example). This assumes no residual value; in practice, you might add a small salvage value (see Residual Value section) instead of depreciating to zero.

Example (Depreciation Method): You bought an olive mill for $100,000 new, which is now 10 years old. Using straight-line (15-year life), its book value would be roughly $100k × (5/15) = $33k remaining. Using diminishing value (13.33% yearly), its book value might be closer to $24k–$25k after 10 years. You could cite these as a range – perhaps saying the machine is “approximately $25k–$33k based on age” – then adjust up or down for condition. If your equipment’s been exceptionally well maintained or lightly used, it might fetch more than the book value; if it’s in rough shape, it could be less.

One of the most practical valuation methods is to see what the market is willing to pay for similar equipment. Check recent listings and sales of comparable olive oil machinery or farm equipment. In Australia, useful platforms include:

Example (Market Comparison): Suppose you own a 10-year-old press (same as above) and find two similar presses listed: one in NSW for $40k (fully serviced, ready for work) and one in SA for $30k (sold as-is, needs some repairs). If your machine is in good working order with maintenance records, the market approach might suggest a value in the high $30k’s. You’d then cross-check this against the $24k–$33k depreciation estimate – if the market seems to be paying a premium (perhaps due to a shortage of used presses), you might lean toward the upper end of the range. On the other hand, if no one is buying presses because many olive groves use custom processing services, you might have to price on the lower end to attract interest.

Another angle is to value equipment based on the income it produces or the savings it provides. This method essentially asks: How much is this machine worth to my farm’s profitability? There are a couple of ways to think about it:

Example (Income Approach): Consider a recently purchased separator (centrifuge) that cost $15,000 new and is only 2 years old. Depreciation might put it at $10k–$12k book value now. But you bought it to improve your oil quality and yield – and indeed, oil yields went up 5%, earning you an extra $5,000 in oil sales each year. If we assume it has at least 8 years of life left, that’s potentially $40k additional income coming. Even discounting future years, the value-in-use of that separator might be on the order of $30k. Of course, no one would pay $30k for a used unit when a new one is $15k, but this tells you that for your own insurance, you might want it covered for replacement cost, and that selling it would only make sense if you exit the business or get a bigger unit. In other words, the ROI approach here tells you the separator is “worth more to me on the farm than to anyone buying it,” so you’d hold onto it unless necessary.

From an insurance perspective, valuation is about ensuring you could replace the equipment if it’s damaged or lost. There are two main concepts used by insurers:

Where to find replacement costs? Contact dealers or check current price lists for the closest equivalent new model. For instance, if your 2008 olive mill is no longer sold, find the price of the current model with a similar capacity. Don’t forget to include freight to your location and installation costs in the replacement figure, as a new machine often involves these. In Australia, companies like The Olive Centre or Olive Agencies can provide quotes for new machinery. We saw earlier that small Oliomio units started around $19.5k a few years back – those prices can guide insurance values for hobby-scale equipment. For larger systems, get a formal quote if possible, since custom setups vary widely.

Also, consider partial loss scenarios: insurance may cover repairs. If you have an older machine, parts might be scarce, so even repairs could approach replacement cost. This is another reason some farmers insure older critical items for replacement cost if they can.

Tip: Document your equipment’s details (serial numbers, specs) and keep evidence of its condition. In an insurance assessment, having maintenance logs, photos, and appraisals can support your valuation. Insurers might depreciate based on a generic schedule, but if you can show your press was fully refurbished last year, you have a case for a higher value. As one farm insurer explains, typically anything over ~8–10 years might only get ACV coverage. If your gear is older but in mint condition or has an ongoing role generating income, discuss options with your insurer – you might opt for a higher agreed value or a policy rider for replacement.

No matter which method you use, don’t forget that machinery usually has some residual value at the end of its useful life. This could be as spare parts, scrap metal, or a second life in a lower-intensity setting. Incorporating residual value prevents undervaluing the asset (and avoids over-depreciating on paper).

When valuing for sale, you might actually set your asking price near the salvage floor if the item is very old. This makes the offering attractive to bargain hunters while ensuring you recover at least scrap value. On the flip side, if you’re buying used equipment, be wary of prices that are at or below typical scrap value – it could indicate the machine is only good for parts.

In summary, always account for the “leftover” value. For insurance, that might not matter (since a total loss is a total loss), but for appraisals and decisions like trading in vs. running to failure, knowing the salvage value helps. For example, if a decanter’s internals are shot, it might still have a salvage value of $5,000 for the stainless steel. That $5k is effectively the bottom-line value no matter what.

Example (Residual Value): You have a 15-year-old tractor that’s been fully depreciated on your books. However, it still runs and could be a backup or sold to a small farm. Checking online, you see similar 80 HP tractors from the mid-2000s selling for around $15,000. That’s the residual market value. Even if you only get $10k due to some issues, that’s far above scrap metal value (maybe a few thousand). Therefore, in your valuation, you wouldn’t list the tractor as $0 – you’d acknowledge, say, a $12k residual value in fair condition. This logic applies to olive equipment too: an old olive washer or oil storage tank might be fully written off in accounts, but it has residual usefulness that someone will pay for.

Each method has its strengths. The table below summarises and compares these approaches:

Each method yields a piece of the puzzle. In practice, when preparing a valuation (for example, for a financial statement or an insurance schedule), you might list multiple figures: “Depreciated value: $X; Likely market value: $Y; Replacement cost: $Z.” This gives a range and context rather than a single uncertain number

Let’s apply the above methods to two concrete scenarios to see how they complement each other:

Scenario 1: Valuing a 10-Year-Old Olive Oil Press

Background: You purchased a medium-sized olive oil press (continuous centrifugal system) 10 years ago for $100,000. It has been used each harvest, processing around 50 tonnes of olives per year. It’s well-maintained, though out of warranty now. You are considering upgrading to a newer model and want to determine a fair sale price or insurance value.

Scenario 2: Valuing a Nearly New Separator (Centrifuge)

Background: You bought a new centrifugal separator (vertical centrifuge for polishing oil) 1 year ago for $20,000. It’s a high-speed clarifier that improves oil quality. Unfortunately, you’re now restructuring your operations and might sell this unit. It’s in “as-new” condition. How to value it?

Valuing farm equipment in Australia comes with some local considerations that can affect prices and depreciation. Here are a few factors particularly relevant to Aussie olive producers:

Depending on your goal – insuring the asset, selling it, or accounting for it – you’ll approach valuation with a slightly different mindset and requirements. Here’s how to handle each:

By implementing the above steps, you not only retain the value of your olive oil machinery but can enhance it relative to similar-aged units on the market. A well-maintained 15-year-old olive press could outperform a neglected 10-year-old press, and its value would reflect that. Many buyers would rather pay more for the former, knowing it was cared for. Good maintenance is like money in the bank for equipment value.

Specialised machinery like over-the-row olive harvesters can hold their value well if maintained, though hours of use and local demand are key factors. For instance, the Colossus harvester pictured (built in Mildura, VIC) had logged about 7,735 hours – yet with components rebuilt and good upkeep, it remains a sought-after asset for large groves. When valuing such equipment, consider service history (e.g. newly rebuilt conveyors or engines), as major refurbishments can extend useful life significantly. Heavy machinery also benefits from many of the tips above: regular cleaning (clearing out olive leaves and dust), timely engine servicing (as per John Deere engine schedules in this case), and storing under cover in off-season all help preserve value. Usage hours are akin to mileage on a car – they directly impact value, but how those hours were accumulated (easy flat terrain vs. rough use) also matters. Keeping detailed records (hours of use per season, any downtime issues resolved) will support a higher valuation when selling to the next operator.

Finally, don’t underestimate the value of operational knowledge and support documents. If you’re handing off a complex piece of gear, providing training to the buyer or passing along your notes (like ideal settings for different olive varieties, or a log of any quirks in the machine and how to manage them) can make your item more attractive, thereby supporting your asking price. It’s not a tangible “value” in dollars, but it eases the sale and might tip a buyer to choose your machine over another.

Valuing olive oil processing machinery and farm equipment requires blending hard numbers with practical insight. By using depreciation formulas, checking market prices, considering the machine’s contribution to your farm, and factoring in replacement costs, you can arrive at a well-supported valuation range. Always adjust for the realities of the Australian market – our distances, climate, and industry size mean context is key. And remember, the way you care for and present your equipment can significantly sway its value.

Whether you’re insuring your olive press, selling a used tractor, or just updating your asset register for the accountant, a thoughtful valuation will pay off. It ensures you neither leave money on the table nor hold unrealistic expectations. Use the following checklist as a guide whenever you undertake a machinery valuation:

Valuation Checklist for Olive Machinery & Farm Equipment:

Valuing farm equipment is part art and part science. The science comes from formulas and data; the art comes from experience and understanding of how your machinery fits into the bigger picture. With the guidelines above, you have tools from both domains at your disposal. Happy valuing – and may your olive machinery serve you efficiently and profitably throughout its life!

Sources