The Sansone 10L Stainless Steel Honey Storage Tank provides a hygienic and reliable solution for beekeepers and food producers. Made from AISI 304 stainless steel, it ensures food safety, corrosion resistance, and ease of cleaning. Equipped with a 1-inch stainless steel honey gate tap, this tank is specially designed to handle viscous liquids like honey, allowing smooth and controlled dispensing.

The wide 130mm opening makes filling and cleaning simple, while the hermetic screw lid with gasket protects contents against air and contaminants. Compact and portable, the 10L tank is suited for both small-scale producers and household use.

| Specification | Value |

|---|---|

| Capacity | 10 L |

| Material | Stainless Steel AISI 304 (18/10) |

| Opening Diameter | 130 mm |

| Height | 240 mm |

| Diameter | 280 mm |

| Weight | 2.4 kg |

| Tap | 1" stainless steel honey gate tap |

| Lid | Hermetic screw lid with gasket |

This 10L stainless steel honey tank is trusted by both professional and hobbyist beekeepers. Its stainless steel body preserves purity and prevents corrosion, while the honey gate tap ensures smooth dispensing of viscous products. The hermetic lid with gasket guarantees airtight storage, keeping honey fresh and uncontaminated. Compact, lightweight, and easy to clean, it balances convenience with professional standards.

Q: Why do beekeepers prefer stainless steel honey tanks over plastic or glass containers?

Honey requires specialised storage because of its thickness, sensitivity to moisture, and long shelf life. Plastic can absorb odours, scratch easily, and is more prone to contamination, while glass is heavy and less practical for bulk storage. Both options may struggle with secure dispensing of viscous liquids.

Stainless steel honey tanks provide a non-reactive, airtight environment that protects flavour, prevents crystallisation from excess air contact, and resists corrosion from natural sugars and acids. The included honey gate tap allows precise, mess-free dispensing—something glass jars and plastic containers cannot offer at scale. For these reasons, stainless steel has become the professional standard for honey storage worldwide.

Key advantages include:

The result is fresher, cleaner, and longer-lasting honey storage, trusted by beekeepers and food producers alike.

Delivery included within Australia.

In the pursuit of advancing olive oil quality, a groundbreaking development for the industry has emerged from a recent study that has illuminated how specific compounds — particularly secoiridoids — can substantially improve the oxidative stability and shelf life of ‘Corbella Extra Virgin Olive Oil (EVOO).

The collaborative Spanish study, carried out at an industrial mill, centered on assessing the influence of malaxation conditions and olive storage on the composition of ‘Corbella’ EVOO, offering insights with potentially transformative implications for the sector.

Extra Virgin Olive Oil is celebrated worldwide for its health-promoting properties and distinctive flavor, establishing itself as a culinary cornerstone across cultures. Nevertheless, its oxidative stability — a key factor in determining shelf life and overall quality — has long been the focus of intensive research. This latest investigation has presented compelling evidence that certain compounds play a decisive role in reinforcing EVOO’s stability.

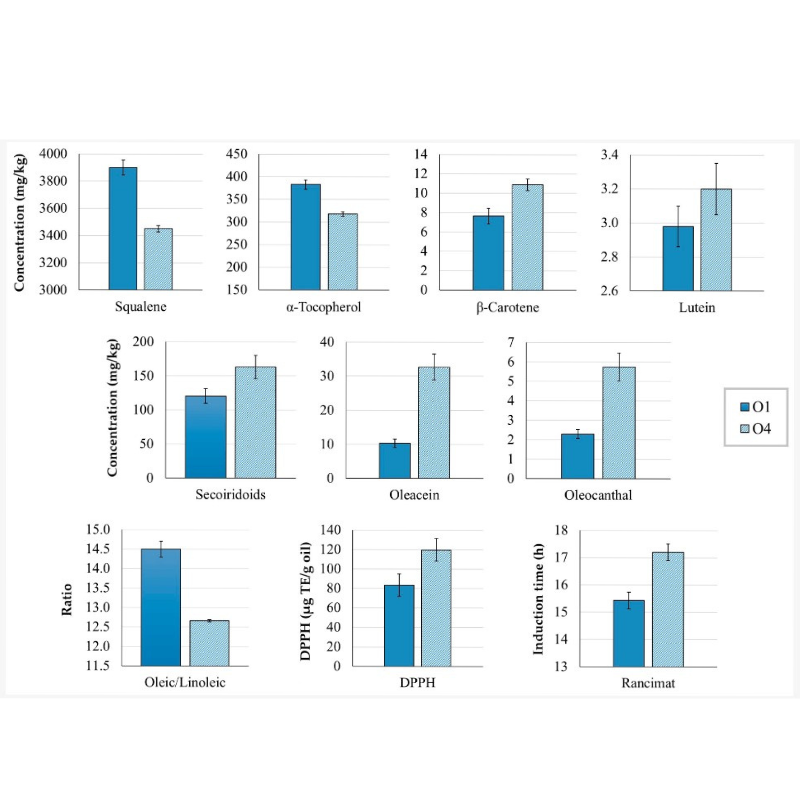

The principal compounds examined included phenolic compounds, tocopherols, carotenoids, squalene, and fatty acids, all of which are fundamental to the oil’s composition. The findings revealed that extended malaxation at higher temperatures, together with olive storage, negatively affected compounds such as α-tocopherol, squalene, flavonoids, lignans, phenolic acids, and phenolic alcohols. However, paradoxically, both the antioxidant capacity and oxidative stability of the oil improved under these conditions. This enhancement was attributed to a marked increase in the concentration of two secoiridoids: oleacein (56–71%) and oleocanthal (42–67%).

Oleacein and oleocanthal are widely recognized for their potent antioxidant activity, and this study has underscored their critical contribution to reinforcing EVOO’s stability and extending its shelf life. In addition, the research identified a synergistic interaction between secoiridoids and carotenoids, further highlighting their collective role in enhancing the resilience and longevity of EVOO.

Concentrations (mg/kg oil) of squalene, α-tocopherol, β-carotene, lutein, secoiridoids, oleacein, and oleocanthal in ‘Corbella’ Extra Virgin Olive Oil (EVOO) samples O1 and O4, along with the oleic/linoleic ratio, antioxidant capacity (DPPH, µg TE/g oil), and oxidative stability (Rancimat induction time, h). Sample O1 was produced on the day of harvest, while O4 was produced the following day using stored olives. Both EVOOs were malaxed at 18 °C for 30 minutes. Data are presented as mean ± standard deviation (n = 9). All parameters showed significant differences (p < 0.05) between samples.

One of the most notable discoveries was the ‘Corbella’ cultivar’s ability to yield EVOOs with a favorable oleic/linoleic ratio. The research indicated that storing olives overnight at ambient temperature, followed by malaxation at no less than 23 °C for 40–50 minutes (depending on the precise temperature), could substantially elevate the concentrations of oleacein and oleocanthal. This increase, in turn, contributed to a measurable improvement in the oxidative stability of EVOOs.

These findings represent a significant advancement in efforts to address and enhance EVOO stability, offering practical applications for producers aiming to extend shelf life while safeguarding quality.

The study also highlighted several promising avenues for future research. Key areas of interest include identifying strategies to further elevate oleacein and oleocanthal levels through agronomic and climatic variables, fruit maturity, and technological aspects of oil extraction.

Moreover, the evaluation of EVOO quality and stability over long-term storage, together with interventional studies assessing the direct influence of these secoiridoids on both product longevity and human health, remains a critical area requiring deeper exploration.

In summary, the research underscores the pivotal role of secoiridoids — particularly oleacein and oleocanthal — in enhancing oxidative stability and extending the shelf life of ‘Corbella’ EVOO. These insights hold dual significance: they offer tangible benefits for producers while also presenting potential health advantages for consumers, marking a milestone in the olive oil industry’s ongoing pursuit of excellence.

Research conducted by Alexandra Olmo-Cunillera 1,2ORCID,Maria Pérez 1,2ORCID,Anallely López-Yerena 1ORCID,Mohamed M. Abuhabib 1ORCID,Antònia Ninot 3ORCID,Agustí Romero-Aroca 3ORCID,Anna Vallverdú-Queralt 1,2ORCID andRosa Maria Lamuela-Raventós

About Secoiridoids

Secoiridoids exhibit a wide range of pharmacological properties, including anti-diabetic, antioxidant, anti-inflammatory, immunosuppressive, neuroprotective, anti-cancer, and anti-obesity effects. These diverse biological activities have significantly heightened scientific interest in the in-depth study of these bioactive compounds.

About Olive Oil Processing Technologies

Olive Oil Processing Plants: Compact Olive Oil Processing Machinery, Processing Lines from 500kgs/hr – 10T/hr & Specialised Machinery to Enhance Your Line

Processing Articles