| Bulk Discounts Prices | |

| Quantity | Price |

| 1 | $405.00 |

The 100L Stainless Steel Olive Oil Tank (Sansone Fusti) is designed for safe and hygienic storage of olive oil and other liquid foods. Made from polished 18/10 stainless steel, it provides airtight protection against light and oxygen while ensuring easy filling, cleaning, and dispensing. Its compact capacity makes it suitable for professional kitchens, tasting rooms, small producers, and enthusiasts requiring reliable bulk storage.

| Specification | Value |

|---|---|

| Capacity | 100 L |

| Material | 18/10 stainless steel (food grade) |

| Opening | 230mm with airtight lid |

| Tap | ½-inch turn-pour tap |

| Measurements | 1.05 x 40 x 40 cm |

| Weight | 9 kg (16.8 kg cubic) |

This Sansone stainless steel tank protects olive oil and other liquids from light, oxygen, and contaminants, ensuring freshness and flavour are preserved. The NSF-certified food-grade stainless steel construction guarantees hygiene and safety, while the wide opening and smooth tap make it easy to use daily. Compact yet practical, it is trusted by professional kitchens and small producers for reliable storage and dispensing.

Q: Why is stainless steel the preferred material for storing and dispensing olive oil?

Olive oil is highly sensitive to light, heat, and oxygen exposure, which can cause oxidation, flavour deterioration, and reduced shelf life. Traditional containers such as plastic or reactive metals may not offer adequate protection, and glass, while useful for small volumes, is less practical for bulk storage.

Stainless steel solves these challenges by providing an airtight, light-resistant, and non-reactive environment. It prevents contamination and oxidation, while the polished interior and welded seams ensure easy cleaning and hygiene. Tanks like the Sansone 100L model also offer controlled dispensing through a fitted tap, making them practical for both commercial and small-scale operations.

Key advantages include:

The result is extended shelf life, preserved flavour, and reliable storage for olive oil and other liquid foods.

In the pursuit of advancing olive oil quality, a groundbreaking development for the industry has emerged from a recent study that has illuminated how specific compounds — particularly secoiridoids — can substantially improve the oxidative stability and shelf life of ‘Corbella Extra Virgin Olive Oil (EVOO).

The collaborative Spanish study, carried out at an industrial mill, centered on assessing the influence of malaxation conditions and olive storage on the composition of ‘Corbella’ EVOO, offering insights with potentially transformative implications for the sector.

Extra Virgin Olive Oil is celebrated worldwide for its health-promoting properties and distinctive flavor, establishing itself as a culinary cornerstone across cultures. Nevertheless, its oxidative stability — a key factor in determining shelf life and overall quality — has long been the focus of intensive research. This latest investigation has presented compelling evidence that certain compounds play a decisive role in reinforcing EVOO’s stability.

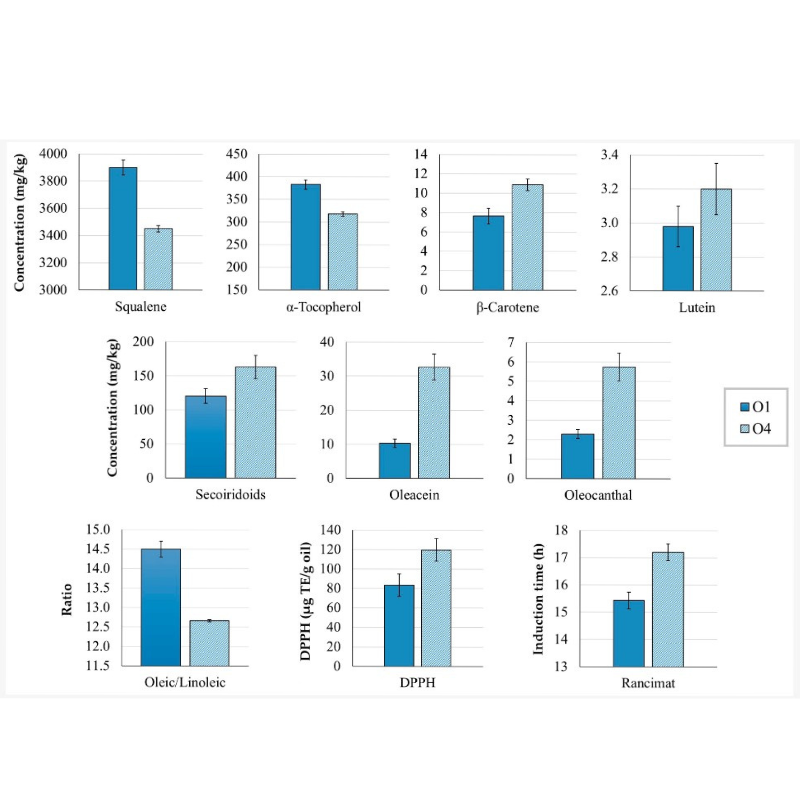

The principal compounds examined included phenolic compounds, tocopherols, carotenoids, squalene, and fatty acids, all of which are fundamental to the oil’s composition. The findings revealed that extended malaxation at higher temperatures, together with olive storage, negatively affected compounds such as α-tocopherol, squalene, flavonoids, lignans, phenolic acids, and phenolic alcohols. However, paradoxically, both the antioxidant capacity and oxidative stability of the oil improved under these conditions. This enhancement was attributed to a marked increase in the concentration of two secoiridoids: oleacein (56–71%) and oleocanthal (42–67%).

Oleacein and oleocanthal are widely recognized for their potent antioxidant activity, and this study has underscored their critical contribution to reinforcing EVOO’s stability and extending its shelf life. In addition, the research identified a synergistic interaction between secoiridoids and carotenoids, further highlighting their collective role in enhancing the resilience and longevity of EVOO.

Concentrations (mg/kg oil) of squalene, α-tocopherol, β-carotene, lutein, secoiridoids, oleacein, and oleocanthal in ‘Corbella’ Extra Virgin Olive Oil (EVOO) samples O1 and O4, along with the oleic/linoleic ratio, antioxidant capacity (DPPH, µg TE/g oil), and oxidative stability (Rancimat induction time, h). Sample O1 was produced on the day of harvest, while O4 was produced the following day using stored olives. Both EVOOs were malaxed at 18 °C for 30 minutes. Data are presented as mean ± standard deviation (n = 9). All parameters showed significant differences (p < 0.05) between samples.

One of the most notable discoveries was the ‘Corbella’ cultivar’s ability to yield EVOOs with a favorable oleic/linoleic ratio. The research indicated that storing olives overnight at ambient temperature, followed by malaxation at no less than 23 °C for 40–50 minutes (depending on the precise temperature), could substantially elevate the concentrations of oleacein and oleocanthal. This increase, in turn, contributed to a measurable improvement in the oxidative stability of EVOOs.

These findings represent a significant advancement in efforts to address and enhance EVOO stability, offering practical applications for producers aiming to extend shelf life while safeguarding quality.

The study also highlighted several promising avenues for future research. Key areas of interest include identifying strategies to further elevate oleacein and oleocanthal levels through agronomic and climatic variables, fruit maturity, and technological aspects of oil extraction.

Moreover, the evaluation of EVOO quality and stability over long-term storage, together with interventional studies assessing the direct influence of these secoiridoids on both product longevity and human health, remains a critical area requiring deeper exploration.

In summary, the research underscores the pivotal role of secoiridoids — particularly oleacein and oleocanthal — in enhancing oxidative stability and extending the shelf life of ‘Corbella’ EVOO. These insights hold dual significance: they offer tangible benefits for producers while also presenting potential health advantages for consumers, marking a milestone in the olive oil industry’s ongoing pursuit of excellence.

Research conducted by Alexandra Olmo-Cunillera 1,2ORCID,Maria Pérez 1,2ORCID,Anallely López-Yerena 1ORCID,Mohamed M. Abuhabib 1ORCID,Antònia Ninot 3ORCID,Agustí Romero-Aroca 3ORCID,Anna Vallverdú-Queralt 1,2ORCID andRosa Maria Lamuela-Raventós

About Secoiridoids

Secoiridoids exhibit a wide range of pharmacological properties, including anti-diabetic, antioxidant, anti-inflammatory, immunosuppressive, neuroprotective, anti-cancer, and anti-obesity effects. These diverse biological activities have significantly heightened scientific interest in the in-depth study of these bioactive compounds.

About Olive Oil Processing Technologies

Olive Oil Processing Plants: Compact Olive Oil Processing Machinery, Processing Lines from 500kgs/hr – 10T/hr & Specialised Machinery to Enhance Your Line

Processing Articles

INDUSTRY UPDATE: AUSTRALIAN OLIVE GROWERS 2023 SEASON

“Earlier in the season, the industry was anticipating an excellent harvest,” Mr Valmorbida said. “However, persistent cold weather and rainfall during May and June, particularly across south-east Australia, have taken their toll.”

Although the Australian olive harvest is not officially recorded each year, the AOOA estimates that the 2023 season will produce between 18 and 19 million litres of olive oil from roughly 110,000 to 120,000 tonnes of olives.

This compares with last year’s output of 14–15 million litres and the record-breaking 2021 crop, which yielded 20–22 million litres of oil.

Mr Valmorbida explained that these fluctuations reflect the biennial cycle of olive production. “This is what we call an ‘on’ year for olives. While we were expecting an excellent yield earlier in the year, harvest results always depend heavily on weather conditions, and this season has been quite mixed for many growers.”

“The oil yield per tonne is noticeably lower than average due to the cooler growing period,” he added, “but the quality of the oil remains excellent because the fruit had more time to ripen gradually.”

Around the world, olive oil prices have reached record highs in Spain, Italy, and Greece, driven by a severe global shortage of olive oil. Hot temperatures, minimal rainfall during key stages of the growing season, and extended drought conditions across southern Spain have drastically reduced European output. In addition, the ongoing conflict in Ukraine has disrupted the production of vegetable and seed oils, increasing global demand for olive oil as an alternative.

In Australia, growers are currently achieving $6–$7 per litre for larger commercial volumes of olive oil, with even higher prices for export batches, premium small-lot oils, and organic extra virgin olive oil.

“With this global shortage, some of the larger Australian producers are in a strong position to export olive oil to Europe and receive competitive returns,” Mr Valmorbida said.

“While that’s encouraging news for the Australian olive oil industry, globally the sector is under pressure,” he continued. “There’s currently a 35–40 percent shortfall in available products, combined with escalating packaging costs, especially for glass and tin materials.”

“These factors, along with rising labour and energy expenses, are leading to higher retail prices for consumers,” he noted.

Mr Valmorbida concluded with a reminder to consumers: “It’s important to remember there’s no product quite like olive oil—its distinctive flavour, health benefits, and culinary versatility make it irreplaceable.”

#oliveharvest2024 #harvest2024

The Australian Olive Oil Association (AOOA) is a not-for-profit, independent organisation dedicated to promoting the quality, integrity, and fair trade of olive oil in Australia. Membership is open to olive oil producers, distributors, industry stakeholders, and related organisations.

Since 1993, AOOA has been a signatory to the International Olive Council (IOC) global quality control program. Each year, the Association coordinates independent laboratory testing of leading olive oil brands to ensure compliance with IOC standards.

In addition, the AOOA Certified Quality Seal Program upholds even stricter quality criteria, allowing AOOA-member products to distinguish themselves in both domestic and international markets.

For more information:

Jan Jacklin, General Manager, Australian Olive Oil Association gm@aooa.com.au www.aooa.com.au

Photo credit: Julia, olive grove – Kyneton Olives” by avlxyz is licensed under CC BY-SA 2.0. To view a copy of this license, visit: https://creativecommons.org/licenses/by-sa/2.0/?ref=openverse

WHAT WE’VE LEARNED FROM YEARS IN OLIVE OIL STORAGE

The Sansone Welded Fusti Tanks represent one of the most trusted stainless steel container designs in the food industry. Manufactured in Italy by Sansone, these tanks are built according to the highest international standards for the preservation of food-grade liquids such as olive oil, wine, honey, and food-grade liquids.

Each unit is produced using 18/10 AISI 304 stainless steel and is NSF certified, ensuring unmatched reliability, purity, and corrosion resistance. Their seamless welded construction guarantees easy cleaning and prevents the accumulation of organic matter or bacterial colonies - a crucial feature for industries where hygiene is paramount.

Built with head-to-head welding technology, the Sansone welded drums are designed to achieve maximum cleanliness and strength. This advanced welding method eliminates internal joints, making the surface completely smooth, which allows for easy sanitation and total prevention of bacterial growth.

These tanks are ideal for food processing, laboratory, and industrial applications that require contamination-free liquid handling. The seamless design also ensures that no residues or flavour transfer occur, maintaining the authentic quality of your stored product.

Each model undergoes strict testing to meet the most rigorous quality standards and is part of Sansone’s commitment to producing long-lasting stainless steel containers that meet professional and domestic needs alike.

All models are equipped with a welded stainless-steel setup for a ½-inch tap, allowing safe and precise liquid dispensing. Each drum can also be paired with optional stainless steel or laminated supports, available in tall and short models with wheels for mobility.

Sansone provides several high-quality accessories to enhance functionality and handling convenience:

Each Sansone welded fusti is produced under ISO 9001:2000 certified quality control systems to ensure consistent performance and reliability. The use of premium-grade 18/10 stainless steel guarantees long life, even under demanding industrial use.

Whether used in olive oil production by producers, wineries, or laboratories, these tanks provide the peace of mind that comes from Italian-made precision engineering, smooth cleaning surfaces, and safe, airtight liquid containment.

For olive oil producers, the Sansone Europa welded tanks provide the ideal environment for oil preservation, protecting against oxidation and contamination while maintaining taste and freshness. The tanks’ sleek finish and robust structure also make them suitable for front-of-house or retail presentation, where hygiene and visual quality are essential.

From boutique olive oil farms to food manufacturers, these stainless steel fusti tanks represent a long-term investment in quality, safety, and professionalism.

If you’re ready to elevate your storage and preservation standards with Sansone stainless steel welded tanks, explore the full range at

https://theolivecentre.com/shop/stainless-steel-tanks-2l-to-99l

As Australia’s leading distributor for Sansone products, The Olive Centre provides expert advice, local support, and fast delivery — helping you choose the perfect stainless steel fusti to suit your needs