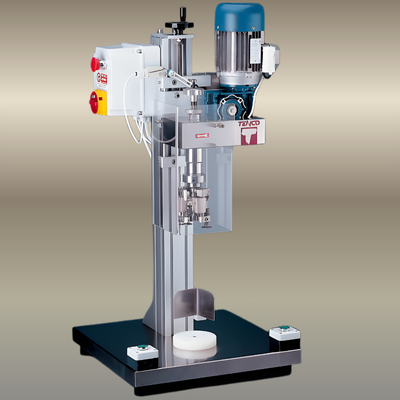

Tenco Automatic Descending Head Capper

The Tenco Automatic Descending Head Capper is a high-precision, automatic magnetic friction capping machine designed for twist-off and plastic screw caps. Built in Italy with stainless steel components, this system guarantees accurate, secure, and repeatable closures for bottles and jars. The operator simply places the container in position and presses both safety buttons simultaneously, activating the descending head that screws and seals the cap in seconds. Capable of closing approximately 600 jars per hour, this model combines speed, precision, and operator safety, making it an essential machine for food, cosmetic, and pharmaceutical packaging applications.

Uses – For Bottling and Packaging Operations

This capper is ideal for use in olive oil, honey, jam, sauce, and condiment bottling lines, as well as for cosmetics and skincare packaging. It provides a reliable solution for small to medium producers who require consistent, torque-controlled sealing for twist-off and plastic screw caps. The descending magnetic head ensures smooth and precise cap placement every time, while the dual-button activation system safeguards the operator during operation. This machine integrates easily into production lines and maintains stable, repeatable results — perfect for ensuring product quality and production efficiency.

Technical Specification

| Specification | Details |

|---|---|

| Product Name | Tenco Automatic Descending Head Capper |

| Model Type | Magnetic friction capper for twist-off and plastic screw caps |

| Manufacturer | Tenco Srl (Italy) |

| Operation | Automatic descending head with dual safety start buttons |

| Production Rate | Approximately 600 jars/hour |

| Head Type | Revolving magnetic head with torque control |

| Cap Pusher | Custom pushers available per cap type |

| Cap Compatibility | Twist-off and plastic screw caps of all sizes |

| Dimensions | Approx. 450 × 450 × 1100 mm |

| Weight | Approx. 50 kg |

| Electrical Supply | 220V - 50/60 Hz single phase / 208V - 60 Hz three phase |

| Construction | Stainless steel and anodized aluminium frame |

| Safety Compliance | CE Certified |

| Delivery | Delivery charges apply |

| File | Title | File Description | Type | Section |

|---|---|---|---|---|

| Tenco_Screw_Capper_HD.pdf | Tenco Automatic Descending Head Capper | Fact Sheet Details | Catalogue | Document |

Introduction

For artisanal olive oil makers and table olive processors, investing in the right equipment can vastly improve efficiency and product quality. TENCO, an Italian manufacturer with roots in Liguria’s olive oil industry, offers a range of compact bottling and capping machines tailored for small to medium operations . These machines are designed to preserve the flavor and integrity of even the most delicate extra virgin olive oil during packaging . From vacuum filling machines that gently bottle oils without exposure to air, to pneumatic dosing systems for viscous olive pastes, and semiautomatic cappers for consistent sealing – TENCO’s lineup (available via The Olive Centre) covers the needs of boutique olive businesses. In this article, we provide an overview of key TENCO equipment models and their features that make them ideal for operations with smaller throughput.

The TENCO Enolmatic is a benchtop vacuum filler designed for small-scale production of oils, wines, spirits, sauces, and other liquids – including those with relatively high viscosity. This compact unit uses vacuum suction to draw product directly from a tank or drum into the bottle, which means the liquid never passes through an impeller pump or mechanical components. This gentle filling method helps maintain the oil’s organoleptic qualities (taste and aroma) by minimising oxidation and turbulence during bottling.

Practical example: Using the Enolmatic, a family olive farm can bottle a 200-litre batch (~266 bottles of 750 ml) of olive oil in just around 2 hours of work, with one person operating. In contrast to manual funnel filling, the vacuum system minimises air contact, preserving the oil’s fresh taste. The adjustable fill level means every bottle looks uniformly filled, which conveys professionalism. If the same farm also packs marinated olives in brine, they can swap to a jar kit and fill jars under vacuum, reducing mess and oxidation of the brine.

For producers who need a higher throughput but still want the benefits of vacuum filling, the TENCO Enolmaster offers an excellent solution. Essentially an upscale version of the Enolmatic, the Enolmaster features four filling heads (stainless steel) operating on the same vacuum principle. This allows parallel filling of 2 or 4 bottles at once, drastically increasing output while retaining a compact, bench-friendly design.

Not all olive-related products are free-flowing liquids. For thicker substances like olive paste (tapenade), olive jam, flavoured sauces, or even cosmetic products (olive oil soaps, creams), TENCO’s Doselite® pneumatic dosing machine is the go-to solution. The Doselite is a volumetric piston filler that uses air pressure to accurately dispense a pre-set volume of product, from as little as a few millilitres up to over a litre. It’s extremely versatile and food-safe, making it well-suited for artisanal producers who handle a range of product viscosities.

Practical example: A small olive producer makes an olive relish and packages it in 250 ml jars. Using the Doselite with a 30L hopper, they can set the dose to ~250 ml and fill jars one after another with foot-pedal activation. The ±1% accuracy means each jar is filled within ~±2.5 ml of the target, virtually eliminating the variance you’d get scooping by hand. With the pneumatic drive, the operator can maintain a steady pace without fatigue – e.g., filling hundreds of jars per hour with consistent weight. Afterwards, cleaning the machine is straightforward: tri-clamp fittings allow the entire product path to be taken apart without wrenches, so cleanup and changeover to their next product (perhaps a lemon-infused olive oil lotion) is quick. The machine’s precision and minimal waste help reduce product loss and ensure every customer gets a full jar with a professional appearance.

Dispensing valves

Dispensing valves

Mixing systems

Once olive oil or olives are filled into containers, the next critical step is secure capping. Hand-capping can be tedious and inconsistent – especially for metal caps that require proper torque or crimping. TENCO provides bench-top capping machines that give small producers a fast, reliable way to cap bottles and jars with professional results. These systems are compact and often pneumatic or electric, making them easy to fit into a small processing room. Below, we highlight two key capping solutions from Tenco and their features:

For olive oil bottles that use pilfer-proof aluminium caps (the type with a tamper-evident ring, often with an integrated pourer insert), Tenco’s descending head capping machine is ideal. This is a semiautomatic electric capper with a 4-roller stainless steel capping head that forms and tightens aluminium caps around the bottle neck thread in one motion. It’s the same style of closure seen on wine bottles (Stelvin® caps) and many olive oil bottles for a leak-proof, tamper-evident seal.

Practical example: A boutique olive oil producer uses the 4-roller capper to seal their 500 ml olive oil bottles with pilfer-proof caps (31.5 mm diameter with pourer inserts). An operator can comfortably cap a bottle in ~5 seconds – aligning the bottle, pressing the buttons, and then removing the sealed bottle – which translates to around 500 bottles/hour at full pace. This is a huge improvement over manually threading on caps and twisting with a hand tool. Moreover, every cap comes out evenly crimped and tightly sealed, preventing the slow drips or oxygen ingress that might occur with uneven hand capping. When the same producer has a run of pickled olives in jars to cap, they switch the capping head on the machine to the magnetic clutch chuck and adjust the height. Now they can cap twist-off jars just as efficiently – ensuring each lid is sealed to the perfect tightness, which reduces product spoilage and extends shelf life by maintaining the vacuum in the jar.

TENCO’s Easycap is a pneumatically-driven bench capper dedicated to twist-off metal lids (common on jars of table olives, jams, etc.) and plastic screw caps. If your operation involves jarring olives, tapenades, or sauces in glass jars with metal lids – or bottling oils/vinegars with plastic caps – Easycap provides a convenient, flexible solution. It’s entirely air-powered (no electricity), which is advantageous in food environments or where compressed air is readily available.

To summarise the discussed TENCO machines, the table below outlines their key specifications and recommended applications:

| Machine & Model | Type | Throughput | Key Features | Ideal Applications |

|---|---|---|---|---|

| Enolmatic (Vacuum Filler) | Single-head benchtop vacuum filler | ~150 bottles/hr (up to 250 for smaller bottles) | Gentle vacuum filling preserves oil quality; adjustable fill level; compatible with many bottle sizes. | Small olive oil producers, boutique wineries, and low-volume premium bottling. |

| Enolmaster (Vacuum Filler) | 4-head benchtop vacuum filler | ~500 bottles/hr (up to 600 optimal) | Four nozzles for high-capacity, no-drip system; stainless steel construction; adaptable with kits. | Medium olive farms, cooperatives, and expanding producers. |

| Doselite (Volumetric Doser) | Pneumatic piston filler | ~500–800 doses/hr (depends on thickness) | Precise 50–1300 ml dosing; handles liquid to thick pastes; food-grade 316L steel; fast cleaning. | Tapenades, sauces, pastes, farm cosmetics, dense olive products. |

| Descending Head Capper (4-Roller) | Semi-automatic electric capper | ~500–600 bottles/hr | Perfect pilfer-proof aluminium sealing; consistent torque; switchable heads for various cap types. | Olive oil bottlers using ROPP caps; producers needing multiple cap formats. |

| Easycap (Pneumatic Capper) | Semi-automatic pneumatic capper | ~500–600 containers/hr | Twist-off lids (38–110 mm) & plastic caps; torque-adjustable; fast mandrel swapping. | Jarred olives, antipasto makers, and producers avoiding electrical equipment. |

(All throughput rates are approximate and assume an experienced operator and continuous operation. Actual rates may vary with product viscosity, fill volume, and operator pace.)

Outfitting a small or medium olive processing operation with TENCO’s specialised equipment can significantly boost efficiency, reduce waste, and improve product consistency. These machines bring industrial-level precision to the artisanal scale: vacuum fillers that protect oil quality while speeding up bottling, piston dosing machines that deliver exact portions of savoury olive products, and semiautomatic cappers that ensure every bottle and jar is sealed tight and secure. Importantly, they are accessible in terms of size, cost, and ease of use – designed with the professional grower/producer in mind rather than a large factory. By adopting such equipment, even a family-run olive grove can achieve a streamlined packing process: imagine bottling and capping your extra virgin olive oil in the morning, with minimal spills or rejects, and confidently offering a shelf-stable, beautifully presented product to customers.

TENCO’s range (available through The Olive Centre) covers each step from filling to capping, and each machine is engineered to handle the nuances of olive products – from preserving delicate flavours to handling viscous textures. This integrated approach helps artisanal producers maintain quality control and scale up throughput without sacrificing the handcrafted appeal of their products. In short, whether you produce boutique olive oil, jarred olives, or related gourmet items, TENCO’s bottling and capping equipment provides a smart investment to elevate your operation’s productivity and professionalism. With these tools, you can save time, ensure consistency, and focus on what you do best: creating excellent olive products.