My Shopping Cart

My Shopping Cart

Preserving the integrity of high-quality foods and liquids - especially extra virgin olive oil (EVOO) - depends on two things: a sound understanding of correct storage parameters and the use of vessels engineered to uphold those conditions with absolute reliability. This is where Sansone, Italy’s premier stainless-steel tank manufacturer, stands far above conventional storage solutions. As global quality standards evolve, the industry has moved decisively away from breathable plastics & reactive metals. With increasing focus on purity, sustainability, and product shelf-life, food-grade stainless steel has become the internationally accepted gold standard for storing oils, beverages, ferments, honey, pharmaceuticals, and more. Within that space, Sansone’s range - distributed in Australia by The Olive Centre - has set the benchmark for durability, hygiene, and performance for over five decades.

International Olive Council (IOC) guidelines highlight the key threats to olive oil quality, i.e. oxygen, light, and heat, each of which accelerates oxidation and rancidity. Proper storage must therefore minimise air contact, prevent light exposure, and maintain stable, cool temperatures.

Sansone’s engineering and material choices align perfectly with these requirements:

1. Oxygen Protection: Airtight Design & Minimised Headspace

The IOC highlights that once a container is opened, limiting headspace is essential to slow oxidation.

How Sansone supports this:

The IOC identifies light as the main threat to olive oil quality after oxygen.

Sansone’s advantage:

The IOC recommends storing olive oil between 13 - 25°C, and notes that lower temperatures (even refrigeration) can slow oxidation.

Sansone excels in temperature resilience:

The IOC emphasises cleanliness, inert materials, and contamination avoidance.

Sansone tanks surpass these needs through:

5. Durability & Long-Term Value: Sustainability Meets Performance

Stainless steel is durable, corrosion-resistant, and 100% recyclable - maintaining its quality through multiple recycling loops. Sansone’s robust construction means a single tank can last decades, dramatically reducing lifecycle costs compared with plastics or coated metals. Their longevity also prevents product loss due to leaks, contamination, or light-induced degradation, making Sansone an economically and environmentally superior investment for producers of all scales.

| Criteria | Plastic Containers | Stainless Steel Containers (e.g. Sansone) | Glass Containers |

|---|---|---|---|

| Material Reactivity | It can leach plasticisers over time, especially with acidic or fatty products. | Completely inert; AISI 304/316 food-grade steel prevents reactions. | Inert to most liquids but may interact with extreme pH. |

| Light Protection | Allows light penetration unless opaque. | 100% light-proof - ideal for olive oil and sensitive liquids. | Transparent unless tinted; light accelerates oxidation. Coloured glass can slow down light penetration. |

| Oxygen Protection / Seal Quality | Moderate; lids may warp or expand, increasing oxygen exposure. | Excellent - airtight seals and precision threads limit oxygen exposure. | Good initially, but seals vary; headspace increases quickly once opened. |

| Durability | Prone to warping, cracking, and UV degradation. | Extremely durable - decades of use without deforming. | Fragile; breaks or chips easily. |

| Temperature Resistance | Sensitive to heat; may warp or release BPA-like compounds/plasticisers. | Highly stable across temperature ranges, including refrigeration and warm environments. | Stable but expands/contracts; risk of thermal shock. |

| Hygiene & Cleanability | Scratches retain residues and microbes; absorbs odours. | Mirror-polished surfaces prevent buildup; no odour retention; easy sanitation. | Very hygienic but difficult to clean if narrow-necked. |

| Impact on Olive Oil Quality | Can accelerate oxidation; not recommended by IOC for long-term storage. | Ideal - protects from light, heat, and oxygen; aligned with IOC guidelines. | Good if dark/tinted and stored cool, but still sensitive to light exposure. |

| Sustainability | Limited recyclability; degrades in quality each cycle. | 100% recyclable without quality loss; extremely long lifespan. | Highly recyclable but higher breakage rate. |

| Weight | Lightweight. | Moderately heavy (depending on tank size). | Heavy and cumbersome, especially in larger volumes. |

| Cost (Upfront) | Low | Higher initial investment | Moderate cost |

| Cost (Lifecycle) | High - due to frequent replacement and product spoilage risk. | Low - one tank often lasts decades; prevents losses from contamination or oxidation. | Moderate - replacement due to breakage or seal failure. |

| Suitability for Industrial Use | Poor - short lifespan and limited hygienic control. | Excellent - used in olive oil production, wineries, pharmaceuticals, honey, and beverage industries. | Limited - weight and fragility restrict large-volume use. |

| Suitability for Long-Term Food Storage | Not recommended. | Excellent - best long-term solution for oils, ferments, beverages, and extracts. | Acceptable for short-to-medium term if protected from light. |

Table. Comparison of Plastic, Stainless Steel, and Glass Containers for long-term storage of food and liquids.

6. Functional Design That Enhances Workflow

Across the entire Sansone range - from 3 L benchtop units to 10,000 L industrial vats - each model is tailored for real-world handling:

These design elements reduce labour time, improve occupational safety, and streamline production lines.

Thanks to their inertness and long service life, Sansone tanks have become essential across multiple industries:

As Australia’s leading supplier of olive and food-processing equipment, The Olive Centre selects only products with proven excellence, traceability, and long-term reliability.

The partnership with Sansone ensures Australian producers - from boutique growers to large commercial processors - gain access to:

When global storage guidelines emphasise controlling light, oxygen, and temperature to protect olive oil and other sensitive liquids, Sansone’s stainless steel tanks don’t just meet these parameters - they optimise them. Their precision engineering, food-safe materials, airtight design, and unmatched durability align perfectly with IOC recommendations, giving producers complete confidence that every drop remains as fresh, pure, and vibrant as the day it was created.

In the world of modern food preservation and processing, few names embody the standards of quality, precision, and hygiene quite like Sansone Inox. Known globally for its mastery in stainless-steel engineering, Sansone continues to lead the industry in food-grade containment technology. Among its most sought-after innovations are its stainless steel silos, designed to meet the demanding needs of producers who value product purity, easy maintenance, and long-term durability.

Now available in Australia through The Olive Centre, Sansone’s Heavy-Duty Silos with Conical Base and Easy Discharge and the Variable Capacity Silos (Sempre Pieno) represent the highest standard in food-safe stainless storage. Built entirely from AISI 304–316L stainless steel, these silos are purpose-built to safeguard liquids like olive oil, wine, honey, vinegar, and other food-grade materials while maintaining their integrity over time.

Each Sansone silo tank is manufactured in Italy under the company’s ISO 9001:2000 quality control standards. The design focus is simple but delivers absolute cleanliness and complete drainage.

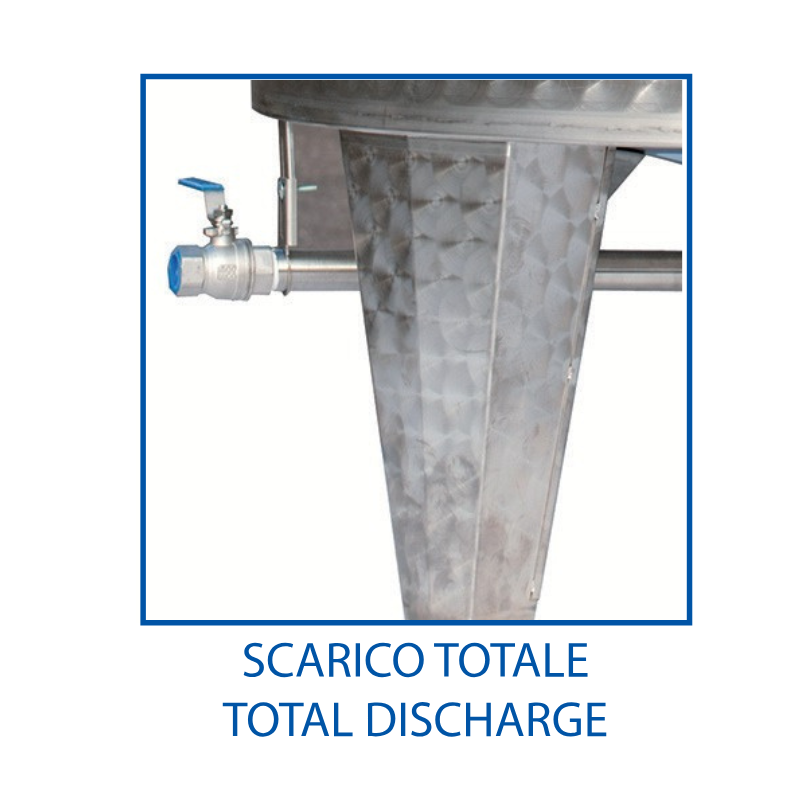

The conical base ensures total discharge of stored contents, preventing residues and eliminating the risk of contamination. Smooth, mirror-polished interiors allow effortless cleaning, while “Polished” or “marble” external finishes offer durability and aesthetic refinement.

Sansone silo tanks are particularly suited for olive oil mills, cooperatives, and cellar doors, where the highest level of product protection is required. The elliptical or round inspection door, double-valve nitrogen system (for fixed capacity type), and stainless steel sampling tap provide users with complete control of the stored product from top to bottom.

Sansone’s Storage Silos with Conical Base and Easy Discharge are designed for fixed installations that demand both hygiene and efficiency. Built from AISI 304 - 316L stainless steel, these silos are ideal for the hygienic storage of liquid foods in environments where contamination-free handling is critical. Each model features a fully welded conical base that ensures total emptying of the tank and minimises product in contact with sediment. The upper cover includes a nitrogen inlet valve, allowing an inert atmosphere for long-term storage without oxidation - especially valuable for olive oil.

The silos are fitted with elliptical front doors, sight gauges, and total/partial discharge valves, making maintenance and inspection straightforward. Every unit rests on reinforced stainless steel legs for stability, ensuring long-lasting service under continuous use.

| Capacity (L) | Height (mm) | Base (mm) | Opening (mm) | Total Height (mm) |

|---|---|---|---|---|

| 1,000 | 1,500 | 950 | 950 | 2,300 |

| 1,500 | 1,500 | 1,100 | 1,100 | 2,600 |

| 2,000 | 1,500 | 1,270 | 1,270 | 2,300 |

| 2,500 | 2,000 | 1,270 | 1,270 | 2,800 |

| 3,000 | 2,000 | 1,430 | 1,430 | 2,800 |

| 5,000 | 2,500 | 1,600 | 1,600 | 3,400 |

Technical specifications sourced from Sansone Stainless Steel Silos documentation. Conical-base silos ensure total drainage and contamination-free storage for food-grade liquids.

These models are ideal for food processing, laboratory, and industrial settings. The seamless conical design ensures total evacuation of liquids while maintaining a contamination-free environment. Each silo undergoes rigorous testing to meet the most demanding quality standards, including leak-proof inspections and pressure-resistance validation.

Optional features include:

For producers who need flexible capacity management, Sansone’s Fixed Capacity Silos - also known as Silos Sempre Pieno - provide a reliable “always full” system that prevents oxidation and product spoilage.

Each tank features a floating stainless-steel lid that adjusts to the liquid level, ensuring no air is trapped between the product and cover. Combined with a conical base, the design facilitates total discharge and makes cleaning fast and efficient.

Manufactured from AISI 304 stainless steel, these silos are the benchmark for wineries and olive mills where maintaining product quality is crucial during storage or decanting. Optional accessories include a level indicator rod, floating arm, and adjustable support legs to guarantee perfect levelling.

| Capacity (L) | Height (mm) | Base (mm) | Opening (mm) | Total Height (mm) |

|---|---|---|---|---|

| 300 | 940 | 640 | 640 | 1,340 |

| 400 | 1,020 | 700 | 700 | 1,420 |

| 500 | 1,170 | 740 | 740 | 1,570 |

| 750 | 1,480 | 800 | 800 | 1,880 |

| 1,000 | 1,480 | 930 | 930 | 1,880 |

| 1,500 | 1,500 | 1,100 | 1,100 | 2,300 |

| 2,000 | 1,500 | 1,270 | 1,270 | 2,300 |

| 2,500 | 2,000 | 1,270 | 1,270 | 2,500 |

| 3,000 | 2,000 | 1,430 | 1,430 | 2,500 |

| 5,000 | 2,500 | 1,600 | 1,600 | 3,100 |

Data sourced from the Sansone Stainless Steel Silos PDF (Variable Capacity Series). Floating-lid Sempre Pieno design ensures oxidation-free storage and total discharge.

Each unit can be equipped with steel air floating lids, anti-alcohol chambers, and stainless pump groups with double valves. From small-scale honey producers to major wineries, these variable-capacity silos provide safe, stable, and efficient storage control.

To complement the Sansone Storage Silos with Conical Base and Easy Discharge, a selection of optional accessories is available to enhance performance, hygiene, and adaptability in food production. These Italian-engineered accessories are constructed from the same AISI 304–316L stainless steel as the silos, ensuring seamless integration and durability under continuous use.

Typical accessories include:

The Variable Capacity Silos (Sempre Pieno) can be upgraded with a wide array of optional accessories designed to provide maximum flexibility for wineries, olive oil mills, and honey producers. These fittings optimise storage management, allowing precise level control, air exclusion, and convenient product transfer.

Common optional features include:

Every Sansone silo is a result of over 40 years of Italian innovation and craftsmanship. The company’s mission remains unchanged - to offer containers that protect both product quality and the planet.

With 100% recyclable stainless steel and exceptional longevity, Sansone silos not only reduce environmental impact but also deliver significant long-term value for producers. Through The Olive Centre, Australian customers can access the full range, local after-sales support, and expert advice on installation, maintenance, and compliance.

Whether you’re preserving the finest extra virgin olive oil or fermenting honey wine, Sansone’s silos deliver unmatched quality and reliability that will stand the test of time.