Waterlogging is a significant challenge in many Australian olive groves due to the combination of heavy clay soils and episodic intense rainfall. Even brief periods of saturated soil (“wet feet”) can harm olive tree health and predispose trees to root diseases. This article explores why waterlogging is harmful to olive trees, how soil factors like clay pans and sodicity contribute to poor drainage, and the link between waterlogged conditions and root pathogens such as Phytophthora and Rhizoctonia. It also outlines how growers and agronomists can diagnose waterlogging risk both before planting and in established groves, and recommends practical prevention and mitigation strategies (from soil mounding and gypsum application to engineered drainage systems) tailored to Australian conditions.

Olive trees require not just water but also oxygen in the root zone for normal function. When soil becomes waterlogged, the air spaces in soil pores fill with water, depriving roots of oxygen. Without sufficient oxygen, root cells cannot respire properly, leading to energy starvation, root damage, and eventually root death. In prolonged waterlogging, this cascade can kill fine roots and impair the tree’s ability to take up water and nutrients, causing symptoms similar to drought or nutrient deficiency despite the excess water. Above-ground, waterlogged olive trees often show leaf wilting, yellowing (e.g., iron chlorosis or nitrogen deficiency from leached soils), and premature leaf drop as roots asphyxiate. In severe cases, entire branches may die back, and the tree can collapse if critical roots rot.

One physiological disorder in olives related to excess soil moisture is oedema, where high soil moisture causes cells near the stem lenticels to engorge and burst. This results in small corky growths on stems, and indicates that roots have been in saturated, low-oxygen conditions. Roots in such conditions may suffocate (“asphyxiate”) due to oxygen depletion, leaving portions of the root system dead or weakened. These weakened roots no longer function effectively and are prone to invasion by opportunistic soil microbes. In fact, waterlogged olive roots are often observed to become infected by normally minor pathogens or decay organisms like Fusarium, Pythium, and various bacteria that exploit the stressed, oxygen-starved tissue. Thus, beyond the direct damage from lack of oxygen, waterlogging indirectly predisposes olive trees to root rot diseases and decline.

It is important to note that olive trees, while drought-hardy, do not tolerate poor drainage. They evolved in well-drained Mediterranean-type soils and will suffer in waterlogged ground. A common adage is that olive trees can “drown” in waterlogged soil. In fact, extension specialists warn that olive trees are often killed by poor drainage when saturated soil conditions persist in the root zone. Even a few days of soil saturation can begin to injure roots; pot experiments in related tree crops show growth reduction after 3–7 days of waterlogging, and shallow stagnant water in hot weather can kill trees within hours. The faster excess water can drain or recede, the better the chances of the olive tree’s survival and recovery. This underscores why good site drainage is critical for sustainable olive production.

Soil properties largely determine whether an olive grove will drain well or waterlog after rain. Sandy or loam soils tend to have ample macroporosity and usually drain freely, whereas clay-rich soils have tiny pores that hold water and allow it to percolate slowly. In dry climates, a clay soil’s water-holding capacity can be beneficial; however, under high rainfall or poor drainage, the same clay can lead to prolonged saturation. Many Australian olive groves are on heavy duplex or clay soils, and naturally well-structured, free-draining soils with deep profiles are hard to come by. (Indeed, as noted for other orchards, ideal soils are “difficult to find in Australia,” and many orchards succeed on marginal soils only through good soil and water management .) Two common soil constraints in Australia that contribute to waterlogging are clay pans and sodicity.

Clay-panning refers to the presence of a dense, hard layer of clay or compacted soil below the surface that roots and water cannot easily penetrate. In olive groves, clay pans can form due to poor soil preparation or natural soil horizons. For example, working the soil when it is too wet or repeated machinery traffic can smear or compact a subsurface layer, effectively creating a “pan”. Additionally, some duplex soils have a naturally abrupt clay subsoil. This hard subsurface layer prevents olive roots from growing downward and also impedes internal drainage, often causing a perched water table to form above the pan during wet periods. The result is that the tree has a shallow, pancake-like root system trapped above the hardpan. Such trees may initially grow okay in dry times, but they become unthrifty and prone to stress-related dieback because their roots are confined to the shallow layer. During heavy rain, water quickly saturates the shallow root zone (since it cannot drain through the pan), leading to temporary waterlogging around the roots. This induces the oxygen deprivation and root stress discussed earlier, compounding the tree’s problems. Conversely, during dry spells, the shallow-rooted tree cannot access deeper moisture below the pan, so it experiences drought stress more readily. Thus, clay-panning creates a double vulnerability: it causes waterlogging stress in wet conditions and drought stress in dry conditions. Affected trees often show chronic ill health and may even blow over in strong winds due to poor anchorage from the shallow roots. In short, a clay pan under an olive grove is a serious impediment to both drainage and root development.

Sodic soils are another common culprit behind poor drainage. A soil is sodic when it has a high proportion of sodium ions attached to clay particles (often measured as Exchangeable Sodium Percentage > 6%). Sodium causes clay particles to disperse (deflocculate) when wet, which plugs soil pores and collapses soil structure. Many Australian agricultural soils are sodic and dispersive – estimates suggest roughly one-third of Australia’s soils have sodicity issues. In Western Australia, for instance, dispersive sodic clays are widespread in duplex profiles, and when these soils get wet, the dispersed clay clogs the pore spaces, drastically restricting water infiltration and drainage. The result is that water sits on or near the surface, creating waterlogged conditions even with moderate rainfall. In medium to high rainfall regions, sodic duplex soils are especially prone to waterlogging because their subsoils percolate so poorly. Once saturated, they also take a long time to dry out. Sodicity often coexists with other constraints like alkalinity or salinity, further complicating management, but from a drainage perspective, the key issue is dispersed clay = sealed pores = no aeration. You can often identify dispersive sodic clays by a milky cloud when a soil clod is dropped in water (dispersion) or by a hard-setting, crusted surface after rains. In field pits, sodic subsoils may appear mottled and dense, indicating periodic perched water tables. Without intervention, olive trees on such soils will struggle each time rainfall leads to a perched water table around their roots.

Gypsum (calcium sulfate) is a well-known amendment for sodic clay soils. The calcium in gypsum can replace sodium on clay particles, helping the clay to flocculate (clump) rather than disperse. This improves soil structure and opens up pore space for better drainage. For olive groves on sodic clay, incorporating gypsum into the soil can significantly improve permeability and reduce waterlogging. The exact amount should be guided by soil tests (gypsum requirement) – often several tons per hectare or a generous application in each planting hole. One practical guideline given by olive advisors is to mix roughly a quarter of a standard bucket of gypsum into each planting hole or tree site when preparing clay soil. This helps “break up” the clay structure and promote drainage. However, gypsum is not a magic fix for all clay issues; it works best if the poor drainage is due to sodicity or dispersive clays. If a hardpan or heavy texture is the issue (rather than sodium dispersion), mechanical soil loosening and surface drainage may be needed in addition to or instead of gypsum. It’s also worth noting that adding gravel or sand to the planting hole will NOT improve drainage in heavy clay – a common misconception. Small gravel in a clay hole can actually create a pseudo-“pot” with water perched on the interface; it’s ineffective at best and harmful at worst. Improving the overall soil structure and profile drainage (through gypsum, organic matter, and deep ripping) or planting above the natural surface (mounding) are more effective approaches for heavy clay.

In summary, understanding your grove’s soil profile is critical. A bit of investigative work – digging soil pits or augering – can reveal if you have an impermeable clay layer or a sodic dispersive subsoil that could cause waterlogging. Identifying these issues before planting allows you to take corrective action (ripping, gypsum, mounding, etc.) rather than watching trees suffer later. As the old adage goes, “plant your olive trees in $10 holes, not 10¢ holes” – investing in soil preparation pays off enormously in preventing water problems down the track.

Excessively wet soils create an inviting environment for certain root pathogens that plague olive trees. Foremost among these is Phytophthora, a water-mold (oomycete) often responsible for root rot and collar rot in olives. Phytophthora thrives in waterlogged soil – it produces motile spores that swim through free water in soil, infecting roots under wet conditions. Not surprisingly, Phytophthora root and crown rot in olive is consistently associated with poorly drained, wet soils, clay pans, or any situation of prolonged waterlogging. Surveys in Australia have isolated multiple Phytophthora species (such as P. palmivora, P. cinnamomi, P. cryptogea, P. citricola, and others) from olive root or trunk rot cases, almost always in groves with drainage problems. Young trees are especially vulnerable – infections often strike within the first few years if a susceptible young tree is planted into waterlogged ground. Infected trees show telltale symptoms: reduced vigor and stunted growth, sparse canopies, dieback of shoot tips, yellowing leaves that drop prematurely, and darkly discolored or rotting roots. Sometimes, a reddish or cinnamon-brown staining under the bark near the crown is seen, and gummosis or cankers may appear at the base. If the disease progresses, parts of the canopy wilt as the decayed roots can no longer supply water, and trees can collapse suddenly during periods of stress (e.g., a hot, dry spell following the wet conditions). Phytophthora root rot can kill trees outright or set them into a decline over several years. An olive grower from NSW DPI noted that Phytophthora root rot is often observed when “excessively wet soils, clay-panning or poor drainage” occur in the grove. This pathogen was particularly problematic in Eastern Australian groves during unusually wet summers; for instance, a spike in olive root rot was reported on the east coast (NSW) following very high summer rainfall in 2008. Australian olive growers must therefore regard Phytophthora as a primary hazard wherever water may accumulate around roots.

Another pathogen of concern is Rhizoctonia, a fungus that causes root rots and “damping off” in many crops. Rhizoctonia in olives has been found in several Australian states, typically affecting young trees or nursery stock. Infected olive roots develop brown lesions, the outer bark may slough off, and under a microscope, you might see the characteristic brown resting structures (sclerotia) on the roots. Above-ground, Rhizoctonia infection can mimic drought stress – leaves get dry tips, yellow, defoliate, and the plant can even die back as if it were water-starved. Interestingly, Rhizoctonia root rot in olive is not as strictly tied to waterlogging as Phytophthora is. Reports indicate Rhizoctonia outbreaks can occur under both dry and moist soil conditions. This fungus often lives in soil and plant debris and can persist through adverse conditions by forming resilient sclerotia. Rather than requiring flooded soil, Rhizoctonia tends to attack when plants are weakened or roots are growing poorly. For example, if waterlogging has damaged roots, Rhizoctonia can invade the dying tissue; conversely, if the soil is very dry and the roots are stressed, Rhizoctonia might also take advantage. In practice, severe Rhizoctonia root rot has mainly been noted in young or potted olive plants. Healthy mature trees are usually less susceptible, presumably because they have more extensive roots and stored resources. Nonetheless, the presence of Rhizoctonia in many Australian olive groves (NSW, SA, QLD, VIC have all reported it ) means that any condition that stresses roots – including waterlogging – could open the door to this pathogen. A waterlogged olive may later show Rhizoctonia root rot symptoms once the soil dries, as the fungus colonizes the damaged root cortex. Thus, water management helps indirectly to prevent Rhizoctonia by keeping roots robust.

In addition to Phytophthora and Rhizoctonia, waterlogged conditions can favor other root diseases: - Pythium species (another water mold) can cause feeder root rot in saturated soils, especially in young trees or nurseries, though it is generally a weaker pathogen than Phytophthora. It often acts as an opportunist on stressed roots. - Fusarium fungi have been isolated from olive roots with rot, showing reddish-brown discoloration and poor growth in young plants. Like Rhizoctonia, Fusarium can persist as hardy spores in soil and tends to strike when plants are predisposed by stress (e.g., excess moisture followed by dryness). - Verticillium dahliae, which causes Verticillium wilt, is a serious olive pathogen, particularly in soils with a history of susceptible crops (e.g., cotton, tomatoes). Verticillium is not directly caused by waterlogging (it doesn’t require saturated soil), but wet, cool conditions can favor its infection cycle. There is some evidence that water stress (either too much or too little) can exacerbate Verticillium symptoms.

Finally, secondary wood decay fungi and bacteria can exploit olive trees after waterlogging injury. Waterlogged roots and lower trunks may develop cracks or cankers (from swelling and shrinkage or bacterial infections), and fungi such as Botryosphaeria or Armillaria (if present in soil) can invade. Australian olive experts have noted that many trunk and branch canker diseases become problematic when trees are stressed or wounded, and waterlogging is one stress that can precipitate those infections. A clear management recommendation from plant pathologists is to “ensure soil drains freely to avoid waterlogging and subsequent root pathogen infections.”. Good drainage is thus a frontline defense against not only Phytophthora and Rhizoctonia, but a whole suite of diseases that take advantage of trees in waterlogged, weakened conditions.

Identifying areas at risk of waterlogging – and detecting early signs of poor drainage – can save growers much trouble. Assessment should be done both before planting a new grove and as an ongoing practice in established orchards (especially after extreme weather). Here are some diagnostic approaches:

Before Planting – Site and Soil Evaluation: Start with a thorough look at the land and soil where you intend to plant olives. Low-lying paddocks, valley bottoms, or sites near river flats are obvious risk zones for flooding and waterlogging. If a site has a history of ponding water after rain or you notice water-loving weeds/reeds in parts of it, take caution. Beyond surface clues, a soil profile examination is extremely useful. Dig soil pits or use a backhoe to create a trench about 1 m deep in representative spots. Inspect the soil layers: is there a distinct, dense clay subsoil? Is there a bleached or mottled layer indicating past waterlogging (gray or orange mottles often mean seasonal saturation)? Look for any “wet layer” or seepage line in the pit – sometimes you’ll find a saturated zone or even seeping water at a certain depth, which indicates a perched water table and poor drainage. Also note any hardpan or compaction layer (for example, from prior farming) – you might see old root growth flattened out horizontally along a hard layer, signaling roots couldn’t penetrate. If you find a compacted or smeared layer in your pit, record how deep it is; that guides how deep you’ll need to break it up (e.g., via ripping).

A simple in-field drainage test can be very illuminating as well. One recommended method is the overnight hole drainage test: dig a hole about 30–40 cm deep and fill it with water. Let it sit overnight. If the water has not fully drained away by the next morning, that soil has poor infiltration and is likely to cause waterlogging issues. Ideally, a well-draining soil will absorb that water within a few hours. If it’s still there after 8–12 hours, you have a problem. Performing this test in a few locations (especially in any suspected heavy soil patches) before planting will tell you where drainage amendments or mounding are necessary.

It’s also wise to test the soil for sodicity and texture through a lab. A soil analysis can reveal a high exchangeable sodium percentage (sodic soil), which would warn you that dispersion and drainage issues are likely unless ameliorated. If laboratory tests or field dispersion tests (like an Emerson crumb test) show the soil is dispersive, plan on applying gypsum or other soil conditioners before planting. Additionally, understanding the soil’s clay content and type (e.g., reactive clays vs. sandy loams) helps predict how prone it is to waterlogging.

After Planting – Monitoring and Early Warning: Once the olive grove is established, growers should remain vigilant, especially in seasons of abnormal rainfall. One straightforward practice is to observe the orchard after heavy rains. Take note of any sections where water pools or drains slowly. Puddles that remain for more than a day, or wheel tracks that stay boggy, are red flags. You might see a greasy shine or algae on soil that stays wet too long. If only small patches are waterlogged, it could be due to a local pan or a low spot – mark those for remedial action (drainage or replanting on a mound, discussed later). Also, inspect the trees themselves for early stress signals. In winter or early spring, when rains are frequent, watch for any trees that develop an overall light yellow hue or begin dropping leaves out of season – this can indicate their roots are struggling from a lack of oxygen or root rot infection in saturated soil. Compare growth and yield: sections of the grove that lag could be suffering from suboptimal root conditions underground (often wet feet or poor soil structure).

A useful technique is to use an auger or spade to check the soil moisture around roots after rain. Dig down near the root zone of a few trees: is the soil waterlogged (gleysolic grey color or foul smell indicating anaerobic conditions)? Does the hole fill with water from below, suggesting a high water table? Healthy, drained soil will feel moist but friable, whereas waterlogged soil may be soupy or have a sewage-like odor (from anaerobic bacteria). Another diagnostic sign in heavy clay soils is a surface crust or hard pan that forms after waterlogging and drying – this can indicate dispersive clay. If you observe a surface crust, you may need to break it up (light cultivation) to allow oxygen back in; its presence also suggests you should address the underlying soil structure for the longer term.

For diagnosing root disease issues related to waterlogging, consider testing suspect trees. If a tree declines after wet conditions, you might have Phytophthora or other root rot at work. Commercial lab services (such as Grow Help Australia or state department diagnostic labs) are available to test soil or root samples for pathogens. For example, SARDI (South Australian Research and Development Institute) offers a DNA-based soil testing service (like Predicta B for broadacre, and similar for horticulture) to detect Phytophthora and other soil-borne diseases before or after planting. These tests can confirm if Phytophthora spores are present in your soil or if a dying tree’s roots have Phytophthora or Rhizoctonia. While such testing incurs a cost, it can be invaluable in pinpointing the cause of decline and informing management (e.g., whether to treat with fungicides or improve drainage, or both).

In summary, before planting, dig and percolation-test your soils to identify drainage issues and rectify them early. After planting, keep an eye (and shovel) on how water moves and dissipates in your grove. Early intervention – whether it’s digging a quick trench to drain water or treating a root rot outbreak – can prevent minor waterlogging from snowballing into major tree losses.

An olive tree in a low-lying part of the grove showing signs of waterlogging: the soil is saturated and puddled around the trunk, and the tree exhibits leaf drop and dieback. Such areas should be identified and addressed proactively (through drainage or mounding) to avoid root disease development.

Preventing waterlogging in olive groves starts with good site selection and preparation, and continues with strategic management and engineering solutions in the field. Below are key methods – both traditional cultural practices and engineered interventions – to keep olive roots high and dry (or at least prevent them from drowning). Emphasis is placed on techniques proven under Australian conditions, where heavy clay subsoils and intense rain events are common.

1. Site Selection and Layout: If you have the luxury of choosing or modifying the planting site, favor locations and layouts that facilitate drainage. Avoid planting olives in natural drainage sumps or flood-prone flats. A gentle slope (even just a 1-2% gradient) is beneficial to shed surface water. If the grove site is flat, you may need to create a slope by laser-leveling or at least plan surface water runoff routes. As a rule, ensure there is somewhere for excess water to go – a lower corner, a dam, a runoff channel – before planting trees. Also consider row orientation and planting density: rows oriented downhill can sometimes act as channels for water flow, whereas contour planting (following the land’s contours) can slow runoff – the best approach depends on your topography and should aim to avoid water accumulating around trunks.

2. Deep Tillage (Subsoil Ripping): For soils with a suspected hardpan or dense clay layer, performing deep ripping or subsoil plowing before planting is highly recommended. Running a stout ripper (with tines that penetrate 50–80 cm deep) through the planting lines will break up compacted layers and fracture the subsoil, improving vertical drainage and root access. Olive experts note that if you have at least ~1.2 m of uninterrupted, well-structured soil profile, you might not need deep ripping. But if a restrictive layer is present at, say, 30–60 cm, ripping is vital. Ripping is often done in two passes (in a cross-hatch pattern) and ideally when the soil is moist (but not wet plastic) to achieve shattering of the pan. In severe cases of textural contrast (e.g., a sharp clay layer), some growers use a slip plow or mouldboard to invert or mix soil layers, but this is a more intensive operation. Deep tillage encourages olive roots to explore deeper and allows rainwater to penetrate the soil profile rather than pooling on top. It must be done well before planting (the season prior) so the soil can settle and rainfall can re-form some structure in the profile. Note that if the subsoil is sodic, ripping alone is not enough – it should be combined with gypsum incorporation so that the shattered clay does not simply disperse and re-seal.

3. Raised Beds and Mounding: One of the most effective strategies for waterlogging-prone sites is to raise the olive tree root zone above the natural ground level. This can be done either by establishing raised beds across entire orchard rows or by mounding individual tree planting sites. In Australia, raised beds have been widely used in other horticulture and even broadacre cropping to manage waterlogging, and the same concept applies to olive groves. A raised bed can be created by heaping and berming soil along the row, typically using a grader blade or bed-forming implement. For individual mounds, soil can be scraped from the inter-row area and piled where the tree will go, or additional soil (preferably a loamy soil) can be imported and added. The mound should be at least 45–80 cm high and about 0.9–1 m in diameter to be effective. In practice, many olive growers aim for roughly knee-height mounds. This elevation ensures that even if water pools in the paddock, the tree’s crown and upper root system are above the saturation zone. It also encourages lateral roots to grow outward into better-aerated topsoil. In South Australia and Western Australia, some growers have reported success planting on long raised berms, especially on duplex clay soils – these berms function like narrow ridges that shed water to the furrows between rows. Raised beds significantly reduce the incidence of waterlogging by allowing excess rain to run off the bed and by improving soil aeration in the root zone. Keep in mind that raised beds can dry out faster in summer, so irrigation might need adjustment (drip lines on top of the mound, etc.). The cost of mounding (earthworks) is an investment, but it is far cheaper than losing trees or yielding to waterlogging. If one cannot mound the entire block, at least mound the low or heavy-soil sections, or mound individual high-value trees.

4. Soil Amendments – Gypsum and Organic Matter: As mentioned, gypsum is the go-to amendment for dispersive (sodic) clays. Applying gypsum in the planting row or even broadcasting and incorporating it into the topsoil can improve soil structure over time. For new plantings, incorporate gypsum into the soil during ground preparation (rates might be in the order of 2.5–5 t/ha or more, depending on soil tests). In an existing grove, surface-applied gypsum (e.g., a band along the tree row) will eventually leach into the soil and help flocculate clay, though incorporation is better if feasible. Gypsum takes effect over months to years, so be patient and reapply as needed based on soil test ESP levels. Alongside gypsum, building soil organic matter can also enhance drainage. Adding compost or manure in moderate quantities can improve soil aggregation and porosity, especially in lighter soils. However, in very heavy clays, too much organic matter at once can actually hold more moisture; the key is a balanced approach. Cover crops or mulches can also improve soil structure over the long term and help create macropores (via root channels and earthworm activity) that assist drainage. Just be cautious that any added organics are well rotted – raw manures can sometimes temporarily worsen structure or tie up nitrogen.

5. Surface Drainage Systems: Engineering the surface water flow can prevent water from ever accumulating around olive roots. A common method is installing spoon drains or diversion banks to channel runoff away. Spoon drains are shallow, broad depressions dug across a slope that act like artificial creeks; they intercept overland flow (or excess rain from a flat) and convey it to a safe outlet (such as a dam or a natural waterway). They can be constructed with a grader and should have a gentle grade to encourage flow. It’s important to place such drains above the orchard or in inter-row areas to catch water before it settles around trees. In flatter groves, even a small ditch (30–40 cm deep) along one side of the block can help drain water out. Ensure any surface drain is kept clear of silt and trash, especially after storms. Also, avoid discharging the water onto a neighbor’s land without permission – route it to a designated drainage line. In orchards that are already planted, growers have dug emergency drains when facing waterlogging; for example, running a single furrow with a tractor through a waterlogged aisle to give water an escape route. While this isn’t ideal for root disturbance, it can save trees in a pinch by getting water off the orchard quickly. Remember, the faster water drains after heavy rainfall, the better the chance your trees won’t suffer.

6. Subsurface Drainage Systems: For chronic waterlogging in high-value groves, a subsurface drainage system may be warranted. This typically involves burying perforated or slotted PVC “agricultural pipes” (aka tile drains or ag lines) below the root zone to lower the water table. A common design is to trench in slotted pipes at a depth of 60–100 cm, in parallel lines across the orchard, with a slight gradient to lead water out to a sump or outlet. These trenches are backfilled with gravel or coarse sand around the pipe to act as a filter and encourage water entry. The spacing of drains depends on soil permeability – heavy clays might need drains every 10–20 m, whereas loams can have wider spacing. Subsurface drainage is best designed by an engineer or experienced drainage contractor because the specifics (depth, spacing, outlet, gradient) are critical for it to function properly. When done correctly, subsurface drains can effectively draw excess water out of the root zone before it causes harm. This solution is more common in larger orchards or where waterlogging is severe and persistent (e.g., an olive grove on a flat clay plain). It is an expensive up-front solution, but it can make an otherwise unviable site productive. Some Australian growers have combined subsurface drains with raised beds – the raised bed keeps the surface roots dry, while the buried pipes lower the overall water table. If you install subsurface drains, also install observation points (e.g., riser pipes or inspection pits) to monitor flow and allow maintenance (flushing out silt, etc.) in the future.

7. Water Management and Irrigation Practices: Growers should also adjust their irrigation strategy to the soil’s capacity. Over-irrigation can mimic waterlogging even on well-drained sites. In heavy soils or areas prone to saturation, use shorter, more frequent irrigation rather than deep, infrequent soaking. Ensure drip emitters are not leaking excessively in one spot. It’s also prudent to pause irrigation if rain is forecast or after heavy rain – monitor soil moisture and only resume when the profile has drained sufficiently. Smart irrigation controllers or soil moisture sensors (tensiometers, capacitance probes) can aid in preventing inadvertent waterlogging from irrigation by giving real-time feedback on soil saturation. Essentially, match your irrigation volume to the soil infiltration rate; any water applied beyond what the soil can absorb will stagnate and harm roots. During cooler months or rainy periods, many Australian olive groves need little to no irrigation – trees can often sustain on stored subsoil moisture until conditions dry out.

8. Remedial Actions for At-Risk Trees: Despite best efforts, you may still find pockets of waterlogging in an established grove – for example, an unexpected seep area or a spot you thought would drain that did not. In such cases, it’s important to take corrective action quickly. For individual trees suffering in a boggy spot, one option (labor-intensive but effective) is to dig out and replant the tree on a mound. Carefully remove the tree during winter dormancy or a cool period, lifting as much of the root ball as possible (or take cuttings if the tree is small and root rot is advanced). Then improve that site – scoop out a wide planting hole, mix in gypsum if clay, and backfill to create a mound 0.5 m or more high – and replant the olive on this raised position. This essentially “rescues” the tree from the swampy ground. It’s best done before the tree is too weakened. Afterwards, monitor it closely for recovery and consider protective fungicide (e.g., phosphite) treatments for root rot.

For larger sections of the grove that prove wet, you might implement a new drain or trench as discussed, even if it means sacrificing a row middle for drainage. Cutting a shallow drain along a contour above the wet area can intercept water, or a deeper trench through the wet area can drain it. These fixes can be done after harvest when equipment access is easier and minor root damage from trenching will be less impactful. Always restore ground cover or mulch over disturbed soil to prevent erosion after digging drains.

9. Disease Management in Waterlogged Situations: If trees have experienced waterlogging, there is a risk of root disease taking hold. As a preventive measure in waterlogged-prone orchards, some Australian agronomists recommend applying phosphorus acid (phosphonate) routinely. Phosphorous acid is a low-toxicity fungicide that is very effective at suppressing Phytophthora in many crops. It can be applied as a foliar spray (commonly at 2.5–10 mL/L depending on product strength) every 6–8 weeks during the wet season. The chemical boosts the tree’s own defenses and can halt incipient Phytophthora infections. In olives, phosphonate is often applied to the leaves (or even as a trunk spray or injection if the canopy is sparse) and allowed to translocate to the roots. This is a preventative approach – it’s most effective when applied before or at the onset of waterlogging conditions, not after a root rot is advanced. If your grove is in a region with warm, wet summers (e.g., Northern NSW or Queensland) where Phytophthora is known to be present, a proactive phosphonate program on young trees can be a lifesaver. Additionally, ensure good sanitation: avoid moving soil from wet infected areas to clean areas (Phytophthora spreads via water and soil), and quarantine any new nursery stock (check their roots for health).

Should Rhizoctonia or other fungi be suspected after waterlogging, there are no specific curative sprays, but improving conditions for the tree to recover is key. This may involve fertilizing the foliage (since compromised roots can’t uptake nutrients well). Foliar feeds of calcium and boron, for instance, have been observed to help olives push new healthy root and shoot growth after water stress. A complete foliar nutrient spray (including NPK and trace elements) can support the tree while its roots regenerate. Prune out any dead or dying branches caused by dieback, but avoid heavy pruning of live tissue – the tree needs as much healthy leaf area as possible to recover. Instead, only remove the clearly necrotic wood and allow any new suckers from the base to grow (they help rebuild the canopy and root system balance). Once the tree shows recovery and the soil has been fixed (drained or mounded), it should regain strength over subsequent seasons.

10. Regional Considerations: Across Australia, the strategies above should be tailored to the local climate. In Mediterranean-climate regions (e.g. South Australia, WA), the highest waterlogging risk is in winter and early spring when rains are frequent – here, focus on winter drainage and perhaps covercropping in summer to maintain structure. In summer-rainfall areas (e.g., eastern Australia), intense downpours can cause flash waterlogging even in midsummer; ensure drainage is ready year-round and be cautious with summer irrigation. In some parts of NSW and QLD, heavy clay soils underlay the valleys – these are classic cases for raised bed planting plus prophylactic phosphonate sprays in the storm season. Contrastingly, in parts of Victoria or southern NSW, waterlogging might coincide with cooler weather, which slows tree metabolism; there, one must be wary of diseases like Verticillium, too, which can co-occur in cool wet soils. No matter the region, always aim to “get the water off the paddock, or get the tree above the water.” A combination of the discussed methods often yields the best result – for instance, ripping + mounding + surface drains + gypsum application might all be employed on a particularly challenging block of sodic clay.

In conclusion, managing waterlogging in olive groves requires diligence in planning, observation, and intervention. The effort is justified by the potentially severe consequences of inaction: tree losses, disease outbreaks, and reduced yields. By understanding your soil’s quirks (clay pans, sodicity) and using the preventive tools available (from mounds and drains to chemical treatments for root rot), you can successfully grow olives on difficult soils and in wet climates. As Australian experience has shown, even marginal clay lands can produce healthy olive crops if waterlogging is kept at bay through smart agronomy. The key takeaways for growers are: prioritize drainage in every decision, regularly inspect and maintain soil structure, and act quickly at the first sign of water stress or root disease. With these practices, olive trees can thrive in regions of heavy rain and clay, yielding bountifully without getting their feet too wet.

INDUSTRY UPDATE: AUSTRALIAN OLIVE GROWERS 2023 SEASON

“Earlier in the season, the industry was anticipating an excellent harvest,” Mr Valmorbida said. “However, persistent cold weather and rainfall during May and June, particularly across south-east Australia, have taken their toll.”

Although the Australian olive harvest is not officially recorded each year, the AOOA estimates that the 2023 season will produce between 18 and 19 million litres of olive oil from roughly 110,000 to 120,000 tonnes of olives.

This compares with last year’s output of 14–15 million litres and the record-breaking 2021 crop, which yielded 20–22 million litres of oil.

Mr Valmorbida explained that these fluctuations reflect the biennial cycle of olive production. “This is what we call an ‘on’ year for olives. While we were expecting an excellent yield earlier in the year, harvest results always depend heavily on weather conditions, and this season has been quite mixed for many growers.”

“The oil yield per tonne is noticeably lower than average due to the cooler growing period,” he added, “but the quality of the oil remains excellent because the fruit had more time to ripen gradually.”

Around the world, olive oil prices have reached record highs in Spain, Italy, and Greece, driven by a severe global shortage of olive oil. Hot temperatures, minimal rainfall during key stages of the growing season, and extended drought conditions across southern Spain have drastically reduced European output. In addition, the ongoing conflict in Ukraine has disrupted the production of vegetable and seed oils, increasing global demand for olive oil as an alternative.

In Australia, growers are currently achieving $6–$7 per litre for larger commercial volumes of olive oil, with even higher prices for export batches, premium small-lot oils, and organic extra virgin olive oil.

“With this global shortage, some of the larger Australian producers are in a strong position to export olive oil to Europe and receive competitive returns,” Mr Valmorbida said.

“While that’s encouraging news for the Australian olive oil industry, globally the sector is under pressure,” he continued. “There’s currently a 35–40 percent shortfall in available products, combined with escalating packaging costs, especially for glass and tin materials.”

“These factors, along with rising labour and energy expenses, are leading to higher retail prices for consumers,” he noted.

Mr Valmorbida concluded with a reminder to consumers: “It’s important to remember there’s no product quite like olive oil—its distinctive flavour, health benefits, and culinary versatility make it irreplaceable.”

#oliveharvest2024 #harvest2024

The Australian Olive Oil Association (AOOA) is a not-for-profit, independent organisation dedicated to promoting the quality, integrity, and fair trade of olive oil in Australia. Membership is open to olive oil producers, distributors, industry stakeholders, and related organisations.

Since 1993, AOOA has been a signatory to the International Olive Council (IOC) global quality control program. Each year, the Association coordinates independent laboratory testing of leading olive oil brands to ensure compliance with IOC standards.

In addition, the AOOA Certified Quality Seal Program upholds even stricter quality criteria, allowing AOOA-member products to distinguish themselves in both domestic and international markets.

For more information:

Jan Jacklin, General Manager, Australian Olive Oil Association gm@aooa.com.au www.aooa.com.au

Photo credit: Julia, olive grove – Kyneton Olives” by avlxyz is licensed under CC BY-SA 2.0. To view a copy of this license, visit: https://creativecommons.org/licenses/by-sa/2.0/?ref=openverse

Introduction

For artisanal olive oil makers and table olive processors, investing in the right equipment can vastly improve efficiency and product quality. TENCO, an Italian manufacturer with roots in Liguria’s olive oil industry, offers a range of compact bottling and capping machines tailored for small to medium operations . These machines are designed to preserve the flavor and integrity of even the most delicate extra virgin olive oil during packaging . From vacuum filling machines that gently bottle oils without exposure to air, to pneumatic dosing systems for viscous olive pastes, and semiautomatic cappers for consistent sealing – TENCO’s lineup (available via The Olive Centre) covers the needs of boutique olive businesses. In this article, we provide an overview of key TENCO equipment models and their features that make them ideal for operations with smaller throughput.

The TENCO Enolmatic is a benchtop vacuum filler designed for small-scale production of oils, wines, spirits, sauces, and other liquids – including those with relatively high viscosity. This compact unit uses vacuum suction to draw product directly from a tank or drum into the bottle, which means the liquid never passes through an impeller pump or mechanical components. This gentle filling method helps maintain the oil’s organoleptic qualities (taste and aroma) by minimising oxidation and turbulence during bottling.

Practical example: Using the Enolmatic, a family olive farm can bottle a 200-litre batch (~266 bottles of 750 ml) of olive oil in just around 2 hours of work, with one person operating. In contrast to manual funnel filling, the vacuum system minimises air contact, preserving the oil’s fresh taste. The adjustable fill level means every bottle looks uniformly filled, which conveys professionalism. If the same farm also packs marinated olives in brine, they can swap to a jar kit and fill jars under vacuum, reducing mess and oxidation of the brine.

For producers who need a higher throughput but still want the benefits of vacuum filling, the TENCO Enolmaster offers an excellent solution. Essentially an upscale version of the Enolmatic, the Enolmaster features four filling heads (stainless steel) operating on the same vacuum principle. This allows parallel filling of 2 or 4 bottles at once, drastically increasing output while retaining a compact, bench-friendly design.

Not all olive-related products are free-flowing liquids. For thicker substances like olive paste (tapenade), olive jam, flavoured sauces, or even cosmetic products (olive oil soaps, creams), TENCO’s Doselite® pneumatic dosing machine is the go-to solution. The Doselite is a volumetric piston filler that uses air pressure to accurately dispense a pre-set volume of product, from as little as a few millilitres up to over a litre. It’s extremely versatile and food-safe, making it well-suited for artisanal producers who handle a range of product viscosities.

Practical example: A small olive producer makes an olive relish and packages it in 250 ml jars. Using the Doselite with a 30L hopper, they can set the dose to ~250 ml and fill jars one after another with foot-pedal activation. The ±1% accuracy means each jar is filled within ~±2.5 ml of the target, virtually eliminating the variance you’d get scooping by hand. With the pneumatic drive, the operator can maintain a steady pace without fatigue – e.g., filling hundreds of jars per hour with consistent weight. Afterwards, cleaning the machine is straightforward: tri-clamp fittings allow the entire product path to be taken apart without wrenches, so cleanup and changeover to their next product (perhaps a lemon-infused olive oil lotion) is quick. The machine’s precision and minimal waste help reduce product loss and ensure every customer gets a full jar with a professional appearance.

Dispensing valves

Dispensing valves

Mixing systems

Once olive oil or olives are filled into containers, the next critical step is secure capping. Hand-capping can be tedious and inconsistent – especially for metal caps that require proper torque or crimping. TENCO provides bench-top capping machines that give small producers a fast, reliable way to cap bottles and jars with professional results. These systems are compact and often pneumatic or electric, making them easy to fit into a small processing room. Below, we highlight two key capping solutions from Tenco and their features:

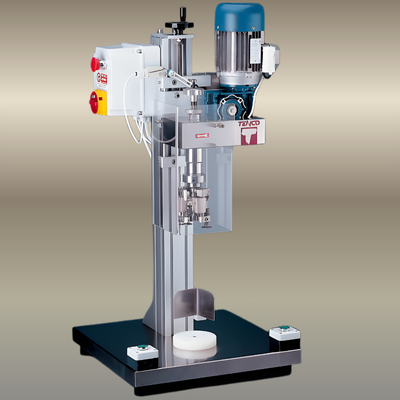

For olive oil bottles that use pilfer-proof aluminium caps (the type with a tamper-evident ring, often with an integrated pourer insert), Tenco’s descending head capping machine is ideal. This is a semiautomatic electric capper with a 4-roller stainless steel capping head that forms and tightens aluminium caps around the bottle neck thread in one motion. It’s the same style of closure seen on wine bottles (Stelvin® caps) and many olive oil bottles for a leak-proof, tamper-evident seal.

Practical example: A boutique olive oil producer uses the 4-roller capper to seal their 500 ml olive oil bottles with pilfer-proof caps (31.5 mm diameter with pourer inserts). An operator can comfortably cap a bottle in ~5 seconds – aligning the bottle, pressing the buttons, and then removing the sealed bottle – which translates to around 500 bottles/hour at full pace. This is a huge improvement over manually threading on caps and twisting with a hand tool. Moreover, every cap comes out evenly crimped and tightly sealed, preventing the slow drips or oxygen ingress that might occur with uneven hand capping. When the same producer has a run of pickled olives in jars to cap, they switch the capping head on the machine to the magnetic clutch chuck and adjust the height. Now they can cap twist-off jars just as efficiently – ensuring each lid is sealed to the perfect tightness, which reduces product spoilage and extends shelf life by maintaining the vacuum in the jar.

TENCO’s Easycap is a pneumatically-driven bench capper dedicated to twist-off metal lids (common on jars of table olives, jams, etc.) and plastic screw caps. If your operation involves jarring olives, tapenades, or sauces in glass jars with metal lids – or bottling oils/vinegars with plastic caps – Easycap provides a convenient, flexible solution. It’s entirely air-powered (no electricity), which is advantageous in food environments or where compressed air is readily available.

To summarise the discussed TENCO machines, the table below outlines their key specifications and recommended applications:

| Machine & Model | Type | Throughput | Key Features | Ideal Applications |

|---|---|---|---|---|

| Enolmatic (Vacuum Filler) | Single-head benchtop vacuum filler | ~150 bottles/hr (up to 250 for smaller bottles) | Gentle vacuum filling preserves oil quality; adjustable fill level; compatible with many bottle sizes. | Small olive oil producers, boutique wineries, and low-volume premium bottling. |

| Enolmaster (Vacuum Filler) | 4-head benchtop vacuum filler | ~500 bottles/hr (up to 600 optimal) | Four nozzles for high-capacity, no-drip system; stainless steel construction; adaptable with kits. | Medium olive farms, cooperatives, and expanding producers. |

| Doselite (Volumetric Doser) | Pneumatic piston filler | ~500–800 doses/hr (depends on thickness) | Precise 50–1300 ml dosing; handles liquid to thick pastes; food-grade 316L steel; fast cleaning. | Tapenades, sauces, pastes, farm cosmetics, dense olive products. |

| Descending Head Capper (4-Roller) | Semi-automatic electric capper | ~500–600 bottles/hr | Perfect pilfer-proof aluminium sealing; consistent torque; switchable heads for various cap types. | Olive oil bottlers using ROPP caps; producers needing multiple cap formats. |

| Easycap (Pneumatic Capper) | Semi-automatic pneumatic capper | ~500–600 containers/hr | Twist-off lids (38–110 mm) & plastic caps; torque-adjustable; fast mandrel swapping. | Jarred olives, antipasto makers, and producers avoiding electrical equipment. |

(All throughput rates are approximate and assume an experienced operator and continuous operation. Actual rates may vary with product viscosity, fill volume, and operator pace.)

Outfitting a small or medium olive processing operation with TENCO’s specialised equipment can significantly boost efficiency, reduce waste, and improve product consistency. These machines bring industrial-level precision to the artisanal scale: vacuum fillers that protect oil quality while speeding up bottling, piston dosing machines that deliver exact portions of savoury olive products, and semiautomatic cappers that ensure every bottle and jar is sealed tight and secure. Importantly, they are accessible in terms of size, cost, and ease of use – designed with the professional grower/producer in mind rather than a large factory. By adopting such equipment, even a family-run olive grove can achieve a streamlined packing process: imagine bottling and capping your extra virgin olive oil in the morning, with minimal spills or rejects, and confidently offering a shelf-stable, beautifully presented product to customers.

TENCO’s range (available through The Olive Centre) covers each step from filling to capping, and each machine is engineered to handle the nuances of olive products – from preserving delicate flavours to handling viscous textures. This integrated approach helps artisanal producers maintain quality control and scale up throughput without sacrificing the handcrafted appeal of their products. In short, whether you produce boutique olive oil, jarred olives, or related gourmet items, TENCO’s bottling and capping equipment provides a smart investment to elevate your operation’s productivity and professionalism. With these tools, you can save time, ensure consistency, and focus on what you do best: creating excellent olive products.