My Shopping Cart

My Shopping Cart

| File | Title | File Description | Type | Section |

|---|---|---|---|---|

| RH-LH.pdf | Rinieri RH or LH positioning for machine | Specifications | Document | |

| Angolo_di_affilatura_disco_Cod.pdf | Angle for Sharpening Blade BRPX | Diagrams | Document | |

| Angolo_di_affilatura_disco_Cod_1.pdf | Rinieri 600mm Blade Sharpening | Manuals | Document | |

| Rinieri_Pruning_Machine_Information_for_Quotation.pdf | Rinieri Pruning Machine - Request to Quote | Specifications | Document |

A successful Grove Management Plan must cover these key areas:

"A grove without an effective irrigation system is unlikely to deliver consistent yields year after year. Many growers still underestimate the water needs of olive trees, and few actually monitor soil moisture levels. This is why so many groves have never achieved a commercial crop." Marcelo Berlanda Specialist Olive Consultant

Water stress negatively affects flowering, fruit set, oil accumulation (oil production), fruit size (table olives), fruit quality, and overall tree health. However, many growers lack a proper system to monitor soil moisture or manage irrigation effectively.

Marcelo recommends:

"Growers should inspect soil moisture weekly during spring and summer, and every two weeks in autumn and winter. Use a shovel to dig at least 400mm under the tree canopy to check moisture. If the soil is hard to dig, it’s too dry – even if the canopy shows no visible signs of stress."

Advanced soil moisture monitoring tools can also provide reliable data on a digital display or computer dashboard.

For optimal grove health, growers must consistently check soil moisture and prevent water stress.

As discussed previously, taking leaf samples is essential to assess your trees’ nutritional status. This information guides the creation of a fertiliser program, a critical component for boosting or maintaining yields.

Typically, no fertiliser is needed in winter, unless you’re addressing soil amendments. However, some groves have severe nutrient deficiencies requiring fertiliser even in winter. Where proper irrigation systems aren’t in place, growers must broadcast fertiliser before rain to allow rainfall to incorporate nutrients into the soil profile, an inefficient use of resources but often the only option.

When applying fertiliser in these conditions, target the area beneath the canopy and, if possible, cultivate the soil to improve incorporation and reduce product loss.

Olives need four essential nutrients: Nitrogen, Phosphorus, Potassium, and Calcium. Check product labels carefully. As a general guideline, aim for:

Avoid pruning during the coldest part of winter and when it’s wet or foggy to reduce the risk of bacterial and fungal disease spread.

The main goals of pruning are to remove dead wood, reduce canopy size, restore tree balance, encourage healthy new growth, and increase fruit set in spring.

Tip: After pruning, apply a copper-based spray to protect wounds from infection by fungi and bacteria.

Pest & disease management is crucial for sustaining yield and tree health. Winter’s colder temperatures reduce insect activity, offering a prime time to tackle pest issues.

Set up a comprehensive Pest and Disease Monitoring Program. During winter, check marked trees (previously affected by pests or diseases) every two weeks; in spring, check weekly. Look under leaves and on new growth for signs like crawlers, yellow spots, black sooty mold, or anything unusual.

Proactive, weekly management is essential for a successful grove.

If you need further assistance, please contact us.

OLIVE HARVESTING

Harvest time in the olive industry is a defining moment for olive oil and table olive producers. Efficient harvesting not only determines yield and profitability but also impacts fruit quality and timing for processing. Traditionally, picking olives by hand with poles, rakes, and nets was an arduous, labour-intensive process - in fact, manual harvesting with rakes and nets can account for 50% of an orchard’s production costs. Today the rising labour shortages and tighter margins, modern growers are increasingly turning to mechanisation to save time and money. The Olive Centre, a specialist supplier for the Australian olive industry, offers a full spectrum of harvesting equipment to address these needs - from state-of-the-art mechanical shakers like the Sicma harvesters to portable electric comb rakes, pneumatic rakes, nets, wheelable frames, and other accessories. This range of tools, paired with research-driven best practices, allows commercial groves to optimise harvest efficiency while maintaining fruit quality. Below, we explore each category of harvesting equipment available through The Olive Centre, focussing on key features, suitable applications, and insights from recent studies and field experience.

Mechanical harvesters are the heavyweights of olive harvesting - high frequency vibration systems built into the machines that shake fruit off trees with speed and efficiency. The Olive Centre provides a leading range of mechanical harvesters, including tractor-mounted shaker heads, skid-steer loader attachments, and dedicated self-propelled “buggy” harvesters. These systems use a vibrating head equipped with a clamp system that attaches to the tree’s trunk or main branches, transmitting high-frequency oscillations that travel with force to the higher branches holding olives to their stems. The result is a rapid cascade of olives into catching systems, often an inverted umbrella or frame beneath the tree. In well-designed groves, a single mechanical shaker can typically harvest 40–60 trees per hour (with a clamp-and-shake cycle of only 5-7 seconds per tree) - a dramatic improvement over manual picking rates. One Australian field review notes the jump from roughly 100 kg of olives per hour using the latest pneumatic or electric hand tools to approximately 500 kg per hour with efficient mechanical harvesting machines. This efficiency in throughput allows growers to bring in the crop at optimal ripeness and throughput, provided the subsequent milling capacity keeps pace.

A Sicma B411 Plus self-propelled olive harvester with its 6 m catching umbrella deployed. The Olive Centre’s partnership with Sicma gives Australian growers access to Italian-engineered mechanical harvesters known for efficiency and robust design.

Modern trunk shakers come in various configurations to suit different operations and grove terrain. The Olive Centre’s lineup includes tractor PTO-driven models (e.g., vibrating heads mounted on a tractor’s three-point linkage or front-end loader), retrofittable kits for skid-steer loaders and telehandlers, and stand-alone self-propelled units often nicknamed “buggies.” For example, the Sicma B411 Plus is a compact 4-wheel-drive buggy harvester with a telescopic vibrating head and a 6-meter diameter catching umbrella. This machine can clamp onto trunks up to ~40 cm in diameter and shake the fruit free, which falls into the umbrella. The built-in catch frame on such harvesters typically holds 200–300 kg of olives, and can be emptied through a hydraulic trap door into bins or trailers for easy collection. Thanks to features like high-frequency self-centering shaker heads and rubberised clamps, these systems minimise bark damage while maximising fruit removal.

In fact, a recent Italian field study on two olive cultivars achieved a 97% fruit removal rate using an advanced vibrating head and catch-frame system - virtually clearing trees in one shake. Mechanical harvesters are the workhorses of modern olive groves, enabling the timely harvest of large tonnages with a fraction of the manpower once required.

Practical considerations: Adopting trunk shakers does require that groves be compatible with the machinery.

Not every olive grove can accommodate a large shaker in their operation, and not every producer needs one. Electric and pneumatic olive harvesters - essentially motorised or air-powered “comb” or “rake” units – fill an important role for small to mid-sized producers and for groves on difficult terrain. These are handheld or pole-mounted tools with vibrating tines that comb through the olive branches, knocking olives off much faster than purely manual picking. The Olive Centre offers several options in this category:

Despite being smaller-scale than trunk shakers, electric and pneumatic harvesters substantially improve productivity over manual hand picking. Field data and grower reports suggest a single worker with a modern pneumatic or electric rake can harvest on the order of 80–120 kg of olives per hour (depending on tree yield and skill) - several times what hand picking would yield. One recent analysis noted about 100 kg/hour as a benchmark using the latest pneumatic or electric rakes. These tools are therefore very useful for reducing labour hours and addressing seasonal labour shortages, which have become a recurrent obstacle in olive production. They also excel in groves where tree spacing or steep hilly terrain make it impractical to bring in heavy machinery. Operators can simply lay out nets under a tree and work through the canopy with the powered rake, a method that is far less fatiguing than beating branches with poles.

Handheld harvesters do require proximity to each tree and are typically used by multiple workers. The efficiency per person is lower than a single large shaker with a catch frame (which can outpace a whole team of people), so producers must balance equipment investment with their useage capability and available labor. In many cases, electric or pneumatic combs are the preferred solution for small olive groves, where gentle handling and selective harvesting might be needed. They cause minimal damage when used properly, though some fruit bruising can occur – so harvested olives, especially table varieties, usually are collected onto nets or padding and not dropped from excessive heights to avoid bruising. Research into gentler harvesting continues: for instance, trials in California have combined canopy shaking with trunk shaking to improve efficiency for table olives. This method increased fruit removal by 75% and delivered higher-quality, less-damaged fruit compared to using either method alone. While such dual-method harvesters are still in development for table olives, it underscores that even in the realm of smaller-scale equipment, innovation is boosting performance. The Olive Centre stays abreast of these developments, supplying trusted brands (like Electric tools by Infaco, & Pneumatic equipment by Lisam) that have a track record in international olive cultivation. For growers, electric and pneumatic harvesters represent a relatively affordable and versatile investment to significantly cut harvest time and labour costs without the need for heavy machinery and a much bigger budget.

Harvesting equipment is not just about the machines that detach olives - it also encompasses all the tools that catch, collect, and transport the fruit once it’s off the tree. The Olive Centre offers a wide array of “catch and carry” accessories to support efficient harvesting operations. Among these are harvest nets and catching frames. Traditionally, tarps or nets are spread under olive trees to collect olives as they are hand-picked or knocked down with poles. Today’s purpose-made olive nets are durable, UV-resistant, and come in various sizes that can be fitted around trunk bases. They drastically reduce the time needed to gather fallen olives and prevent fruit loss on the ground. Some modern harvesters use an umbrella-style catching frame – essentially a large circular net on a frame that can be deployed under the tree (either by a person or as an attachment on a machine) to catch olives as they rain down. The Olive Centre offers products like a 5–6 m diameter catching frame that can be positioned around the trunk to funnel olives into an Industry-standard Orange Crate and will fit about 20kgs of fruit per crate. Such frames can be a game-changer for groves still harvested by hand or with electric or pneumatic combs, as they keep fruit off the soil (maintaining cleanliness and quality) and make collection faster.

Image: Major Catching Harvest Frame

The introduction of nets and basic mechanical aids in the mid-20th century was one of the first steps to mechanising olive harvests, replacing ladders and ground picking to reduce work time and safety risks for workers.

Another staple harvest accessory is hand rakes and picking tools. These simple, hand-driven rake devices (often plastic combs capable of making them a reachable unit by installing a broom handle) allow pickers to strip olives from branches more efficiently than by handpicking each fruit. A broom handle sourced at a local hardware store can be inserted into the back of the handle to make these reach greater heights. The Olive Centre’s catalogue includes these manual rakes that are useful for growers starting out, for very small operations or used with a large team. .

Picking bags and baskets are also important: workers can wear a picking bag to drop olives into as they hand-pick or move along the rows, then empty the bags into crates or bins periodically. Good picking bags distribute weight, are not too large and often have a quick-release bottom to safely transfer olives without spillage and impact which minimises bruising.

Crates and bins round out the harvest accessories – The Olive Centre provides vented plastic orange olive crates (around 15–20 kg capacity each) and heavy-duty pallet bins (~400 kg capacity) to safely store and transport harvested olives. These containers are food-grade and ventilated to prevent heat buildup or fermentation of olives before milling. They can be moved with tractors or forklifts, streamlining the post-harvest logistics.

Image: Orange Olive Crate

When it comes to moving bulk olives in the field, trailers and bins become essential. Many mechanical harvesting setups integrate with trailers; for example, a tractor shaking unit might drop fruit onto a towed trailer with a catching cloth, or a self-propelled buggy like the Sicma has its own bin reservoir that can be emptied into a trailer via a trap door. Even independent of mechanical shakers, growers often use tractor-pulled trailers to ferry filled pallet bins from the grove to the processing area. The Olive Centre can supply specialised bin trailer equipment and tipping mechanisms that make this process more efficient. The overall goal of all these accessories is to preserve fruit quality and save labour between the tree and the mill. Every hour saved collecting olives from the ground or transferring them to storage is efficiency gained in getting the olives to processing, which can be critical for oil quality. Research consistently emphasises rapid processing of olives after harvest (generally within 24 hours is best practice) to maintain low free fatty acidity and high polyphenol content. By using proper harvest aids - nets to keep olives clean, bins to avoid fruit piles overheating, and trailers to quickly haul fruit - producers can better achieve those quality goals.

Equipping an olive operation with the right tools is half the battle; the other half is using them in an optimised harvest strategy. Fortunately, extensive academic and industry research offers guidance on how to mechanise effectively without compromising the olives. One key concept is fruit detachment force (FDF) - essentially, how strongly an olive is attached to its branch. FDF decreases as olives ripen, which is why oil olives (allowed to ripen longer) are generally easier to remove, whereas table olives (picked green) are much more stubborn. A University of California study noted that table olives have a fruit removal force of about 0.5 kg - meaning they require significantly more shaking or even chemical loosening to enhance fruit removal. Oil olives, usuall progressed in manturation (compared to green table fruit), have a lower detachment force, and modern high-density oil cultivars are usually harvested by over-the-row machinery like an Moresil, Oxbo, New Holland or Colossus. This explains why trunk shakers and canopy shakers are an innovation mainly needed for table olive orchards (to address their high FDF), whereas oil olive groves in super-high-density (SHD) systems can be harvested by modified grape harvesters that strip fruit with minimal effort. For producers, understanding their varieties’ detachment characteristics can inform which equipment to use and whether strategies like applying an abscission agent (fruit loosening spray) might be worthwhile. In ongoing trials, compounds like ethephon are being tested to reduce olive attachment strength and thus increase mechanical harvester efficiency. Use fruit loosening agents with caution as improper use can defolate the entire tree.

Another insight from research is the importance of grove design and pruning in mechanical harvesting success. A tree with an open, accessible structure (single trunk, properly managed canopy) should yield better results with shakers. Studies from Europe have documented that tree architecture and pruning style significantly affect vibration transmission and fruit removal. Many growers now implement mechanical pruning and keep trees shorter to accommodate harvest machinery - a necessary adaptation as “there is no mechanical harvesting without orchard and canopy adaptation,” as one agricultural engineer famously put it. This might mean switching to hedgestyle planting (250–300 trees/ha) if one plans to use over-the-row harvesters, or simply maintaining a 6– 8 m spacing and a vase or single leader form for traditional orchards using trunk shakers. The Olive Centre, beyond just providing equipment, also provides grove consulting services to help producers plan such transitions, ensuring that investments in machinery are matched by an orchard setup that maximises efficiency and minimises fruit loss.

Finally, research confirms that speed and timing of harvest are crucial for quality. Mechanical harvesters enable a very fast picking .... entire blocks can be harvested at the optimal ripeness window rather than stretched over weeks. By concentrating harvest in the optimal period, growers can obtain olives at peak oil quality and get them milled promptly.

Evidence from studies in Spain and Italy shows that when olives are harvested at the right maturity and processed quickly, mechanisation does not impair oil quality metrics; on the contrary, timely harvesting can result in higher-quality extra virgin olive oil compared to a protracted hand harvest, where some fruit inevitably becomes overripe or delays in processing occur due to extended time duration needed.

For table olives, minimising bruising is a bigger concern, and the research offers pointers - for instance, experiments have shown harvesting in the cool pre-dawn hours can reduce fruit bruising and respiration, improving the condition of mechanically harvested table olives. Such findings are encouraging producers to adjust harvest schedules and techniques (e.g., adding padding to catch frames or using conveyors instead of dropping olives into bins) to protect fruit quality.

Tthe modern olive grower has an unprecedented range of harvesting equipment at their disposal, and when these tools are coupled with informed practices, the results are compelling: lower costs, higher efficiency, and preserved quality. Offering industry leading equipment - from Sicma’s cutting-edge shakers to nimble electric rakes, and all the supporting gear - reflects the evolving landscape of olive harvesting. By leveraging both technology and research-based know-how, commercial olive producers can confidently tackle the critical harvest season, bringing in the crop efficiently and at peak quality to ultimately produce better oil and table olives for the market.

Harvesting will always be a pivotal and challenging aspect of olive production, but it no longer needs to be a bottleneck. The range of equipment available through TheOliveCentre.com empowers growers to choose solutions tailored to their grove size, layout, and production goals. Whether it’s a robust mechanical harvester shaking 500 kg of olives per hour into an umbrella, or a team of workers with electric combs and nets swiftly stripping trees on a hillside, each approach offers advantages that can improve the bottom line. Importantly, ongoing innovation - much of it supported by academic and government research from Australia and abroad - continues to refine these tools and techniques for greater efficiency, ensuring that higher productivity does not come at the expense of fruit quality. With The Olive Centre’s expertise and equipment range (including their partnership with world-class harvesting machine manufacturers), Australian olive growers have access to the best of both worlds: advanced technology proven in international groves, and local knowledge and support to implement it successfully. The result is a harvest that’s faster, easier, and more profitable – helping producers focus on what comes next, turning those olives into exceptional oil and table olives for consumers to enjoy.

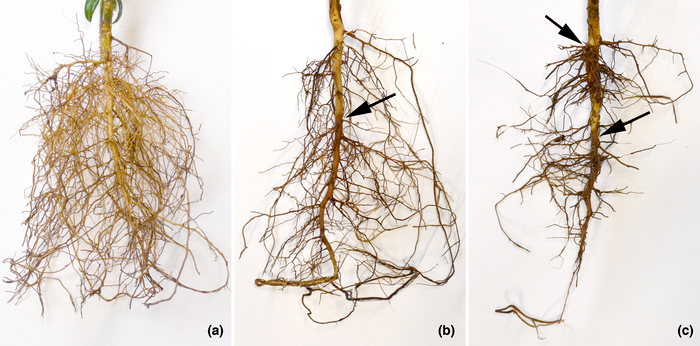

Phytophthora root rot is a destructive soil-borne disease of olive trees caused by Phytophthora species (water-mould pathogens). At least seven Phytophthora species have been identified attacking olives in Australia . These pathogens infect roots and can extend into the lower trunk, causing root decay and crown cankers that girdle the tree. If left untreated, Phytophthora root rot can kill olive trees, either through a rapid collapse or a slow decline over several seasons . The disease has been observed in many olive-growing regions worldwide, often linked to periods of excessive soil moisture.

Symptoms: Infected olive trees typically show a loss of vigour and drought-like symptoms even when soil moisture is adequate. Foliage becomes sparse as leaves wilt, turn yellow, and drop prematurely . Shoot dieback starts at the tips of branches and progresses downward. In advanced cases, entire limbs or the whole canopy may wilt suddenly, especially under stress conditions like hot weather, flowering or heavy fruit load . Root and trunk symptoms include soft brown rot of feeder roots and lesion-like cankers at the crown or lower trunk; peeling back bark at the base often reveals reddish-brown discoloration of the wood. Affected trees may respond by shooting new suckers from the lower trunk or roots as the upper canopy dies back . Over time, the trunk can exhibit cracks or distortions due to the underlying canker damage . In some cases, trees can decline gradually over years, whereas in other cases they collapse quickly when the compromised root system can no longer support the canopy (for example, during a heatwave or late summer) .

Waterlogging and Poor Drainage: Excess soil moisture is the single biggest contributing factor to Phytophthora root rot in olives. Phytophthora thrives in saturated, oxygen-deprived soils. Australian conditions have consistently found Phytophthora outbreaks correlated with waterlogged conditions, claypan soil layers, or generally poor drainage in groves. Even a short period of waterlogging (as little as 24 hours) in warm temperatures can kill fine olive roots and predispose trees to infection. Low-lying orchard areas, heavy clay soils that drain slowly, or sites with a high water table create ideal conditions for the pathogen. It’s important to note that while waterlogging is a common trigger, Phytophthora can sometimes cause problems even in well-drained soils if the pathogen is present and environmental conditions (temperature, soil moisture) become favourable. In high-rainfall climates or during unusually wet seasons, otherwise well-drained olive blocks may still experience Phytophthora issues if drainage cannot keep up with prolonged rainfall.

Susceptible Rootstocks: Most olive trees in Australia are grown on their own root stock (i.e., not grafted), but in cases where different rootstocks or wild olive (Olea europaea subsp. africana) seedlings are used, susceptibility can vary. Caution is advised when using feral/wild olive trees as rootstocks or nursery stock. These plants can originate from areas where Phytophthora is present in the soil and may introduce the pathogen or be less tolerant to it. There is currently no widely available Phytophthora-resistant olive rootstock, so all varieties should be assumed susceptible. Research by Spooner-Hart et al. noted that the emergence of Phytophthora problems in Australian olives has coincided with the expansion of plantings into non-traditional (non-Mediterranean) climates and heavier soils. This underscores the role of environment and rootzone conditions in disease incidence.

Warm, High-Rainfall Climates: Olives are traditionally adapted to Mediterranean climates (winter rain, dry summers). In parts of Australia with warm temperatures and summer-dominant rainfall (e.g., coastal Queensland and northern New South Wales), the risk of Phytophthora root rot is higher. The pathogen is widespread in soils and waterways in these regions and can easily infect olive roots when wet, warm conditions persist. Growers in such climates must be especially proactive with prevention measures. High humidity and frequent rain not only favor the pathogen but can also mask early drought-stress symptoms - an infected tree might not show obvious distress until a dry period or heat event reveals the extent of root loss.

Disease Spread: Phytophthora produces motile spores (zoospores) that swim in free water, so the pathogen spreads with water movement through soil and runoff. It can be introduced or spread in a grove via infected nursery stock, contaminated soil on equipment, flood irrigation water, or even the boots of workers moving from an infested wet area to a clean area. Once in the soil, Phytophthora can persist for years in root debris or as resilient spores. Thus, any practice that moves soil or water (e.g., tractor(s) and farm equipment, drainage flows) from an infected zone to an uninfected zone can facilitate the dissemination of the disease. Growers should avoid transferring mud and material from known infested blocks and ensure any new trees planted are from disease-free sources (pathogen-free).

Successful management of Phytophthora root rot in olives relies on an integrated strategy. This includes preventative chemical treatments, supportive nutritional therapies, and cultural practices to improve soil conditions and reduce pathogen spread. The goal is to protect healthy roots from infection, eradicate or suppress the pathogen in soil where possible, and help affected trees recover. Below are the current industry best practice:

Phosphorous acid (also known as phosphonate or phosphite) is a key fungicide for mana PhozGuard 620 Phytophthora in many tree crops and is a cornerstone of preventative treatment in olives. Phosphonate does not act like a typical fungicide that directly kills the pathogen on contact, instead, it works by inhibiting Phytophthora growth and stimulating the tree’s own defense mechanisms. This dual mode of action makes it most effective as a preventative treatment, applied before or at the very early stages of infection, to help the plant resist invasion. Phosphorous acid is available under various trade names (e.g., Phosguard620) with different concentrations of active ingredient. Always confirm that the product is permitted for use on olives and follow the label or permit directions.

Application timing and rates: On woody perennial crops like olives, foliar sprays of phosphonate are typically applied approximately every 6 weeks during the growing season for ongoing protection. This ensures a consistent level of the fungicide within the plant, as it is systemic and will move into the roots. Label rates depend on product concentration; for example, products with around 600 g/L a.i. are used around 2.5 mL/L, 400 g/L formulations at 5 mL/L, and 200 g/L formulations at 10 mL/L (when applied with an air-blast sprayer to fully cover the foliage). For young or small olive trees, high-volume spraying to runoff ensures good coverage. Crucial timing is just before periods of high risk - e.g., before winter rains or summer wet spells - so that the roots are protected in advance.

In situations where an olive tree has very little foliage left (severe defoliation from root rot), phosphonate can be applied as a bark spray or trunk injection. Spraying a ~10% phosphorous acid solution directly on the trunk or injecting the solution into the lower trunk can deliver the fungicide to the vascular system when leaves are insufficient. Trunk application is usually done in autumn or spring when the tree is actively translocating, to maximise uptake. Always exercise caution with concentrated trunk sprays to avoid phytotoxicity and adhere to recommended concentrations carefully.

Mode of action and benefits: Once absorbed, phosphonate is translocated downward with the sap flow, reaching the roots and inhibiting Phytophthora in infected tissues. It also primes the tree’s immune response. Treated trees often show not only disease suppression but also improved new root development in some cases. Phosphonate is valued for being relatively inexpensive and having low toxicity to humans and non-target organisms, making it a practical choice for routine preventative use. In warm, high-rainfall regions of Australia where Phytophthora is endemic, applying phosphonate prophylactically to young olive trees can protect them until their root systems establish. Many agronomists recommend an initial phosphonate spray or injection soon after planting in such regions, followed by periodic treatments during the wet season.

It’s important to remember that phosphonate is a suppressive, not an eradicant, treatment. It significantly reduces Phytophthora levels and activity in the tree but does not eliminate the pathogen from the soil. Therefore, repetitive or at least annual reapplications are needed to maintain protection. If treatments are stopped, Phytophthora can rebound if conducive conditions return. Also, phosphonate works best on preventing new infections and halting early disease - severely diseased trees (with the majority of roots already rotted) may not recover with fungicide alone. In those cases, phosphonate can only prevent further spread while other measures support the tree’s regrowth.

Other fungicides: Another chemical option is metalaxyl-M (e.g., Ridomil Gold), a systemic fungicide specifically targeting oomycete pathogens like Phytophthora. Ridomil can be applied as a soil drench or via injection to kill Phytophthora in the root zone. It has shown effectiveness in olives, but similar to phosphonate, it does not sterilise the soil and must be reapplied periodically to keep the pathogen in check. Phosphonate is often preferred for long-term management due to lower cost and resistance risk, but Ridomil drenches can be useful as a curative kick-start in heavily infested soils or to protect newly planted high-value trees. Always rotate or mix chemical modes of action as allowed, to prevent the development of fungicide resistance in the Phytophthora population.

As an example for conventional application... Calcium nitrate at 10 g/L plus Solubor (boron) at 1.5 g/L, mixed in water, applied as a fine foliar spray every 6 - 8 weeks. Calcium nitrate provides a readily absorbed form of calcium (along with some nitrogen to spur growth), and Solubor is a common soluble borate fertiliser that assists to correct boron deficiency. These can be tank-mixed and sprayed to cover the foliage; ideally, apply in the cooler part of the day (morning or late afternoon) to reduce the risk of leaf burn. Liquid boron applications like Agrodex Boron are usually recommended.

In addition to fungicides, nutritional support plays a critical role in managing Phytophthora root rot - especially for helping infected trees recover. Two nutrients in particular, calcium (Ca) and boron (B), have been observed to assist olive trees suffering from root rot. Calcium and boron are closely associated with the growth of new shoots and root tips; they are essential for cell wall strength (Ca) and cell division/floral development (B). Some olive varieties have relatively high requirements for Ca and B compared to other fruit trees, and deficiencies of these nutrients often manifest as dieback of shoot tips (boron deficiency can cause tip death and poor new leaf growth, while calcium deficiency leads to weak stems and twig dieback).

When roots are compromised by Phytophthora, the tree’s ability to uptake nutrients from the soil is severely impaired. Ailing roots mean even if fertilisers are in the soil, the tree may still suffer from nutrient deficiencies. Foliar feeding can bypass the damaged root system and deliver nutrients directly to the leaves and young shoots. Foliar sprays of calcium and boron have shown positive results in reducing twig dieback and stimulating new growth on moderately affected olive trees. The recommended practice (from field experience in Australia) is to apply calcium and boron together on a regular schedule during the active growing season:

It’s worth noting that while calcium and boron are the focus for tip dieback, other nutrients should not be neglected. Trees battling root rot might also benefit from magnesium (for chlorophyll), zinc (for hormone production), and other micronutrients if deficient. However, over-applying any one element can cause imbalances or toxicity (boron, for instance, can be toxic above recommended rates). Stick to label rates and recommended concentrations for all foliar feeds, and monitor leaf nutrient levels if possible. The Ca+B foliar program should be seen as one component of a broader nutritional management plan for stressed trees. Start with Soil and/or Leaf Analysis to ascertain data from your grove.

Beyond calcium and boron, a complete foliar nutrient program is advised for olive trees with significantly impaired root systems. Because root rot limits uptake of both macro- and micro-nutrients, foliar applications of a balanced fertiliser can supply the tree with essential nutrients until roots recover. Many agricultural suppliers offer soluble foliar fertiliser blends (NPK plus Trace Elements) that can be sprayed on the canopy. These blends often contain nitrogen, phosphorus, and potassium, as well as micronutrient like zinc, manganese, iron, copper, molybdenum, etc., in plant-available forms. Applying such a foliar feed can green up a chlorotic, declining tree and promote new leaf and root development while bypassing the diseased root system.

A suggested regimen is to spray a complete foliar fertiliser (for example, an NPK 20-20-20 with trace elements, or a product formulated for orchard foliar feeding) on a monthly or bi-monthly schedule during the growing season. This can often be done in conjunction with the calcium nitrate and boron sprays - either by alternating them or, if compatibility is confirmed, combining them in one tank mix. Be cautious when mixing fertilisers with fungicides: phosphonate is generally compatible with many fertilisers, but always jar-test combinations or consult product labels.

Foliar nutrient programs should be tailored to the grove’s specific deficiencies. If leaf analysis or visual symptoms indicate particular nutrient shortages (e.g., yellowing between veins might indicate magnesium or iron deficiency, small, distorted new leaves could indicate zinc deficiency), include or emphasise those nutrients in the foliar mix. Maintaining good overall nutrition will improve the tree’s resilience. Stronger, well-nourished olive trees have a better chance to compartmentalise Phytophthora infections and resume normal growth once conditions improve. Remember that these sprays supplement but do not replace soil fertilisation; once roots recover function, reinstating a normal soil fertiliser program (adjusted for any residual soil fertility and the tree’s regained capacity) is important for long-term production.

Cultural controls that improve the soil environment are fundamental to managing Phytophthora - no chemical or nutrient can fully substitute for a well-drained root zone. Growers should evaluate their grove for any conditions that contribute to waterlogging or poor root health and take corrective action:

Both phosphonate fungicides and calcium-boron foliar feeds are important tools in managing Phytophthora root rot, but they serve different purposes and have distinct advantages and limitations. It’s not an either/or choice - in fact, they are complementary in a comprehensive management program. Below is a comparison to clarify their roles for growers:

It’s also worth comparing phosphonate with the other fungicide option, metalaxyl (Ridomil). Phosphonate and Ridomil both suppress Phytophthora, but in different ways. Ridomil is more of a curative, directly toxic to the pathogen, whereas phosphonate has those immune-boosting properties. Ridomil can knock back an active infection faster, but it has a higher cost and a risk of resistance development in the pathogen population with overuse. In practice, phosphonate is often used for regular protection, and Ridomil (if used at all) might be reserved for spot-treating severe cases or as a pre-plant soil drench in known infested sites. Both chemicals require reapplication; neither provides permanent protection. Always follow an Integrated Disease Management philosophy when using these tools - they are most effective when combined with the cultural and nutritional strategies described above.

Managing Phytophthora root rot requires an Integrated Disease Management approach, especially in Australia’s warm, high-rainfall olive-growing regions. No single intervention is a silver bullet; instead, growers should implement a suite of preventive and remedial measures that together minimise disease impact. Below is a summary of IDM practices for Phytophthora root rot in olives:

Managing Phytophthora root rot in olives is challenging, but with vigilant management, it is possible to minimise losses and even restore affected groves to health. The keys are prevention (through site selection, drainage, and preventative fungicides) and support (through nutrition and careful cultural care for stressed trees). Australian olive growers should view Phytophthora management as an ongoing part of grove management, much like pruning or pest control, especially in regions prone to heavy rainfall. By implementing the integrated strategies outlined above, growers can significantly reduce the impact of Phytophthora root rot, protecting their trees and investment. Remember that every grove is different - monitor your olive trees closely and adapt these recommendations to local conditions, and always reference current guidelines from olive industry research and local agricultural authorities. With a proactive, informed approach, even the threat of “root rot” can be managed, and olive trees can continue to thrive and produce in the Australian landscape.

Introduction

Managing a professional olive production enterprise requires a holistic operational system that covers every aspect of grove management – from seasonal field practices to financial tracking and technology integration. This report outlines a comprehensive system designed for professional olive producers in Australia (with relevance internationally), detailing best-practice management structures, cost tracking methods, data monitoring and decision-support tools, forecasting techniques, and ready-to-use workflows and templates. By implementing a structured approach with clear planning, recordkeeping, and modern tech integration, olive growers can improve productivity, sustainability, and profitability. The following sections break down the components of this system with practical guidelines and examples.

Effective olive grove management is multi-faceted, involving year-round planning and execution of tasks. It is helpful to organise these tasks by season and category, ensuring nothing is overlooked throughout the year. Table 1 provides an overview of key seasonal activities in an Australian context (southern hemisphere), which can be adjusted for other regions (the timing of seasons will differ in the northern hemisphere ). Each activity should be supported by detailed record-keeping and adherence to best practices for orchard maintenance, irrigation, nutrition, pest control, pruning, and harvest.

Proactive seasonal planning is vital. By mapping out activities month-by-month, growers can ensure each critical task is done at the right time. Many producers use a yearly task calendar or planner to schedule operations. For example, the Australian Olive Association’s Yearly Orchard Planner outlines monthly tasks ranging from machinery servicing in the off-season to timely fertiliser applications and harvest prep. Such a planner ensures cross-over tasks (e.g. tractor maintenance benefiting both grove and other farm enterprises) are efficiently scheduled. It’s important to adjust the calendar to local climate patterns and whether the grove is in the southern or northern hemisphere. Regular planning meetings (e.g. before each season change) can help assign responsibilities and resources for upcoming tasks.

Accurate record keeping underpins all aspects of the operational system. Every activity – from spray applications to harvest yields – should be logged. This not only aids internal decision-making but also is often required for compliance (e.g. chemical use records) or quality assurance programs (such as the OliveCare® code of best practice ). Key records to maintain include:

General orchard maintenance activities ensure the grove’s long-term health and accessibility. These include ground cover management, upkeep of equipment, and maintaining the orchard environment:

Efficient water management is crucial for olive production, especially in Australia’s climate, where seasonal droughts are common. Olives are relatively drought-tolerant, but strategic irrigation greatly improves yield and oil quality in most Australian growing regions. Key components of irrigation management include:

Overall, irrigation in an olive operational system should be proactive and precision-focused. Given water scarcity concerns, Australian producers in particular benefit from these efficient practices – a fact evidenced by large groves like Boundary Bend investing heavily in irrigation technology research to “use less water but retain optimum productivity”. Well-managed irrigation not only saves water and energy, but also directly contributes to consistent yields and oil quality.

Proper fertilisation of olive trees ensures they have the nutrients needed for vegetative growth, fruiting, and recovering after harvest. The nutrition program should be based on soil and leaf analysis plus the grove’s yield goals. Key points include:

Pest and disease management in olives should follow an Integrated Pest and Disease Management (IPDM) approach. This means using a combination of monitoring, cultural practices, biological controls, and chemical controls when needed. Key elements for a professional group include:

Pruning is a cornerstone of olive grove management, directly influencing yield, tree health, and harvest efficiency. A well-structured pruning program in a professional system includes:

Harvest is the culmination of the season and requires careful logistical planning to execute efficiently and preserve fruit quality. A comprehensive operational system addresses harvest in several ways:

By detailing harvest logistics in the operational system, a grower ensures that this critical period is handled smoothly. It’s often said that in olives, “90% of the quality is influenced by what happens on the farm” – timely harvest and proper handling are a big part of that. Thus, the comprehensive plan treats harvest not as a rushed event but as a well-orchestrated project each year.

Understanding and controlling the cost of production is essential for a sustainable olive business. This part of the system involves setting up templates and tools to track all costs, from orchard inputs to labour and equipment, and calculating metrics like cost per hectare and cost per tonne of olives (or per litre of oil). A professional approach includes:

| Cost Category | Example Items | Cost (AUD/ha) | Share of Total (%) |

|---|---|---|---|

| Labour – Harvest | Picking crew wages or harvester contract, supervision, and fuel | $1,200 | 35% (highest single cost) |

| Irrigation | Water purchase, pumping energy (diesel/electric), irrigation maintenance parts | $600 | 18% |

| Fertilisation | Fertilisers (N, P, K), soil amendments, and application labour | $550 | 16% |

| Pruning | Labour or contract pruning, tool maintenance, brush mulching | $450 | 13% (varies by manual vs mechanical) |

| Pest & Disease Control | Pesticides, fungicides, traps, application labour (spraying) | $300 | 9% |

| Other Labour (non-harvest) | Irrigation management, mowing, and general supervision (portion of manager wages) | $200 | 6% |

| Machinery & Fuel | Tractor fuel, maintenance, depreciation (portion allocated) | $150 | 4% |

| Miscellaneous | Monitoring tech, insurance, admin, etc. | $100 | 3% |

| * Total (per hectare per year) | $3,550 | 100% | |

Table Note: The above breakdown is illustrative. Actual costs will differ by grove and system (e.g. superintensive groves might have higher harvest costs due to machinery leases but lower per-unit labour, etc.). The IOC study figures in the table (italicised) are from a traditional system example and show the relative importance of harvest, irrigation, and fertiliser inputs. Tracking your own costs allows you to refine these numbers for your operation.

Modern olive farming can greatly benefit from data-driven decision support, using sensors and information technology (the realm of IoT – Internet of Things and smart farming). Integrating such systems into daily operations turns raw data (weather, soil moisture, pest counts, etc.) into actionable insights. In this comprehensive system, the following integrations are recommended:

To run a sustainable olive operation, one must not only react to the present conditions but also anticipate the future. Forecasting tools help in predicting yields, planning resources and finances, and strategising for the long term. This section details how to incorporate forecasting into the operational system:

In the operational system, it’s wise to formalise yield forecasting. For instance, schedule a “yield forecast review” meeting mid-season (maybe 6–8 weeks post flowering) to discuss all available info (fruit set, tree health, etc.) and come to a forecast. Update it again just before harvest with more solid numbers (e.g. from sample picking an olive bin from a tree or small plot and weighing). Document these forecasts and later compare them to actual yield to improve your methods over time.

Forecasting is not only about yield – it’s equally about financials. A robust operational system will include:

By treating budgeting and financial forecasting as an integral part of the operational system (rather than an afterthought at tax time), professional growers ensure that agronomic decisions are grounded in financial reality. It also impresses stakeholders (banks, investors) when the business can show proactive financial planning.

Beyond the annual scale, a comprehensive system should guide strategic planning over the long term:

To translate all the above components into day-to-day action, the system should provide clear workflows and ready-to-use templates. These resources ensure consistency, save time, and serve as training tools for staff. Below are some of the key templates and checklists recommended, along with their purpose:

In the resources library of industry organisations, many of these templates are available. The Australian Olive Association, for instance, provides resources like the Yearly Orchard Planner, an IPDM manual, and other guides which include checklists and record sheets (often accessible to members). International bodies like the IOC or FAO have Good Agricultural Practices manuals that contain sample record forms. The key is to adopt and customise these to your farm’s needs, then consistently use them.

By having structured workflows and templates, the operation runs in a systematised way rather than relying on memory or ad hoc decisions. This reduces risk (e.g. missing a spray or forgetting to service something) and improves training – new staff can quickly learn the ropes by following established formats. Moreover, in the event a manager is away, the existence of clear checklists and templates means the team can continue to function with minimal disruption, since the “recipe” for tasks is documented.

To support the comprehensive system described, certain technologies and software tools are highly beneficial. Below, we provide recommendations for tools that are either commercially available or emanate from credible research institutions, ensuring they are reliable and suitable for professional use. These cover farm management platforms, specialised olive cultivation tools, and general agtech solutions:

In conclusion, a comprehensive operational system for professional olive producers weaves together agronomic best practices, detailed record-keeping, cost management, and technology integration and planning into one coherent framework. By implementing a structured management calendar, maintaining meticulous records of both activities and expenses, and leveraging modern sensors and software, growers can achieve a high level of control and insight into their operations. This system is designed to be holistic – covering the soil beneath the trees to the finances underpinning the enterprise – and adaptive, allowing for localisation (Australian conditions in this context, but with practices applicable globally) and continuous improvement as new knowledge or tools emerge.

Crucially, the system emphasises that planning and monitoring are as important as doing. Seasonal checklists and annual planners ensure proactive management rather than reactive firefighting. Cost templates and forecasting tools ensure that production is not just good in the grove but also economically sustainable. Meanwhile, data from IoT sensors and decision support models enable precision farming – applying the right intervention at the right time and place, which is both cost-effective and environmentally responsible.

Implementing this comprehensive system may require an initial investment in time (to set up templates, train staff) and capital (for technology or new equipment), but the returns are seen in higher yields, better quality, lower wastage of inputs, and improved ability to cope with challenges (be it a pest outbreak or a drought year). As demonstrated by progressive growers and supported by research, the integration of traditional olive cultivation wisdom with cutting-edge agtech forms the blueprint for the future of olive production.

By following the structured approach outlined in this report, professional olive producers in Australia – and those in similar olive-growing regions worldwide – can enhance the productivity and sustainability of their groves. They will be well-equipped to produce olive oil and table olives of the highest quality, with an operation that is efficient, resilient, and ready to capitalise on innovations and market opportunities. The ultimate goal of this system is to ensure that every aspect of the olive orchard, from bud to bottle, is managed with excellence and foresight – securing both the profitability of the enterprise and the legacy of the grove for years to come.

Sources:

SMART PRUNING FOR STRONGER, HIGHER-YIELD OLIVE TREES

By Marcelo Berlanda, Agronomist & Consultant for The Olive Centre

“Olive trees must put out fresh growth each year to produce fruit.”

Training shapes the tree to support efficient harvesting and encourage early production

When trees reach the canopy size best suited to their environment, yields may begin to drop. This often happens because the inner canopy receives limited sunlight, leading to leaf loss and a reduced Leaf-to-Wood Ratio. If a tree grows beyond its ideal size, it creates challenges for mechanical harvesters. Excess height and width, along with thick branches, can strain or damage harvesting equipment, reduce fruit removal efficiency, and slow the harvest. Because olive trees need to produce new shoots annually to maintain fruiting, consistent growth is essential—and pruning becomes an important management practice. Pruning improves fruit size, oil content, light penetration, and the Leaf-to-Wood Ratio. It also stimulates fresh growth and lowers water and fertiliser demand.

1- TREE TRAINING

Purpose: Establish early productivity with stronger yields, extend the productive lifespan of the tree, enhance fruit quality, and prepare trees for the harvesting system used in the grove.

Timing: Training occurs within the first three years of the tree’s development.

In the first year, pruning is minimal (assuming nursery trees arrive with a good structure). Remove lower or overly vigorous branches that compete with the central leader. The goal is to maintain an upright main trunk with outward-growing horizontal branches. Water shoots should be removed so they do not compete for nutrients and moisture.

During the second and third years, gradually remove lower branches below approximately 600–1000 mm.

A balance is essential. Removing too much canopy reduces the tree’s photosynthetic area, slowing its progress until new growth resumes.

Light pruning involves removing only small sections of foliage (such as a few short shoots), which keeps the tree stable. This can be done from August through late May.

Heavy pruning removes larger amounts of foliage, prompting a stronger regrowth response but also increasing frost risk. Heavy cuts should generally be delayed until late September unless conditions are warm enough to begin earlier.

Tree training may also include tying and skirting as part of shaping and preparation.

2- PRODUCTION

Young trees contain many non-productive branches because they are still actively growing. Once these branches mature and begin producing fruit, they eventually become exhausted and stop fruiting. At that point, they need to be removed to make room for new productive growth and renewal of the canopy.

LoIf the bloom is light, pruning should focus mainly on non-productive wood to preserve as much fruiting potential as possible. In years with heavy bloom, pruning can be more assertive without significantly reducing the crop.

Timing: From bud break through early December.

3- AFTER HARVEST (CLEANING)

The goal at this stage is to remove large damaged branches left behind after mechanical harvest. This step can be postponed by applying copper after harvest and waiting until spring to remove the affected wood.

Read More: ● Marcelo Berlanda ● Mechanical Pruning ● Mechanical Harvesting

Marcelo Berlanda’s “Pruning for Production” guide highlighted why olive pruning is vital to sustain yields. This article builds on that foundation, focusing on how to encourage the growth of productive fruiting wood in Australian olive groves.

Olive trees bear fruit on one-year-old shoots – the growth produced in the previous season. Ensuring a steady supply of these young, fruitful shoots each year is critical for consistent yields. Without renewal, canopies fill with aging wood that carries fewer leaves and buds, leading to lower productivity. Pruning is therefore geared toward a few fundamental objectives :

Understanding how and when olive fruiting buds form helps refine pruning practices. Unlike deciduous fruit trees, olives do not have a true winter dormancy – their buds remain in a state of quiescence and will grow when conditions permit. Flower buds initiate relatively late: studies have shown that olive buds begin differentiating into inflorescences about 2 months before bloom (around late winter/early spring in the local climate). This means the buds on this year’s spring flowering shoots were formed in the late summer or autumn of last year, on the previous year’s wood. Crucially, those buds needed sufficient resources and light while they were forming.

Several physiological factors influence fruitful bud development:

Takeaway: Productive fruiting wood arises from a balance – neither too vegetative nor too weak – and it needs sunlight. Pruning is the tool to create that balance by removing what’s unproductive and making space for fruitful shoots under the right environmental conditions.

Having set the physiological context, we now turn to pruning methods that encourage renewal of fruiting wood. The approach will vary with the age of the tree and the orchard system (traditional vs. high-density), but several general principles apply:

By applying these pruning techniques, growers encourage a continuous supply of young fruiting wood while avoiding the pitfalls of over-pruning. The result is a tree that renews itself gradually: always plenty of 1-year shoots ready for the next crop, and no big shocks to the tree’s system.

Olive orchards in Australia range from traditional low-density plantings to modern high-density (HD) and super-high-density (SHD) groves. The principles of fruiting wood renewal apply to all, but the methods and intensity of pruning are adjusted to each system’s needs :

In summary, the pruning strategy must fit the system: gentle but regular for intensive hedges, somewhat heavier but less frequent for large traditional trees, and always aimed at keeping enough young wood in the pipeline. Regardless of system, the fundamentals remain: capture sunlight, encourage new shoots, and remove what’s unproductive.

Pruning not only influences yields – it also plays a significant role in Integrated Pest and Disease Management (IPDM). A well-pruned olive canopy is generally healthier and easier to protect. Here’s how encouraging productive wood ties in with pest and disease considerations:

In summary, a sound pruning regimen is a cornerstone of IPM in olives. It reduces pest and disease pressure naturally by altering the micro-environment and improving the efficacy of other controls. Always balance the need for opening the canopy with the tree’s productive capacity – a healthy medium density (not too sparse) is the target, so that you don’t invite sunscald or stress. With those caveats, pruning is one of the most cost-effective pest management tools a grower has.

Beyond pruning itself, several environmental and cultural factors influence how well an olive tree can produce new, fruitful wood. Understanding these helps growers create conditions that favour the continual renewal of fruiting shoots:

In summary, productive fruiting wood is not just about cutting branches – it’s the outcome of the whole orchard management system. Pruning is the mechanical stimulus, but water, nutrients, and overall tree stress levels determine how the tree responds. The best results come when pruning is synced with these factors: prune to shape the growth, irrigate and fertilise to support it (but not overdo it), and protect the tree from stresses that could derail the process. By doing so, growers in Australia can maintain olive canopies that are youthful, vigorous, and laden with fruitful shoots year after year.

Encouraging productive fruiting wood in olives is both an art and a science. The art lies in “reading” the tree – knowing which branches to remove and which to spare – while the science lies in understanding olive physiology and applying evidence-based practices. In this follow-up to Marcelo Berlanda’s pruning guide, we have underlined the key strategies:

Sources: This article integrates findings from peer-reviewed studies and reputable industry publications, including research by Gómez-del-Campo et al. on light and yield distribution, Tombesi and Connor on pruning and olive physiology, Rousseaux et al. on bud dormancy and flowering, and Australian olive industry resources (NSW DPI, AOA IPDM manual) on best practices. These sources reinforce the recommendations above and ensure advice is aligned with the latest understanding of olive tree management.